RFID with HF bus mode monitors seed storage

KWS optimizes and secures its seed production with TURCK's BL ident RFID solution for wireless identification and temperature monitoring of silo boxes – including Profinet S2 system redundancy

Quick read

As the global market leader for sugar beet seed, KWS Saat SE & Co. KGaA supplies its customers with seed varieties specifically tailored to their requirements for conventional and organic farming. To achieve this, the seed must be propagated and processed under suitable climatic conditions. In this highly automated processing process for sugar beet seed, TURCK's RFID solution BL ident ensures the contactless transmission of energy, address data and measurement values from temperature sensors inside silo boxes, thus ensuring high system availability – also through Profinet S2 redundancy of the RFID interfaces. The option of automatic address assignment and TURCK's unique HF bus mode for connecting up to 32 HF read/write devices per port guarantee fast installation, efficient storage, and simple device replacement in the event of servicing.

As one of the world's leading seed specialists for maize, sugar beet and cereals, KWS Saat SE & Co. KGaA uses state-of-the-art plant breeding methods to increase farmers' yields and further improve the resistance of plants to diseases, pests and abiotic stress. To this end, the seed must be propagated and processed under controlled climatic conditions and in accordance with the highest quality standards. In sugar beet seed production at its Einbeck site, KWS processes sugar beet seeds in a highly automated, multi-stage process. Between the individual process steps, the seeds are transported fully automatically in boxes and stored in a dynamic high-bay system. To ensure seed quality, it is necessary to be able to determine and monitor the temperature inside the storage boxes – at any time and as accurately as possible.

High availability thanks to Profinet S2 system redundancy

The seeds must meet certain requirements, for example with regard to tolerance to various diseases or drought. The relevant data is exchanged and processed in the system between a server and the control system. "If silo data were lost as a result of a control system failure, it would no longer be possible to trace which seeds are stored in which box," says Christian Fricke, . In this case, there would be no other option but to dispose of the seeds that can no longer be assigned. This is obviously undesirable for a high-priced product that cannot be reproduced at short notice."

The required storage system must therefore guarantee maximum availability and data security. Profinet-based systems can be designed for this purpose with a redundant control system, referred to in the Profinet specification as S2 redundancy. TURCK's compact TBEN-RFID interfaces with Profinet S2 system redundancy for high-availability systems meet this requirement. In the event of a control-related failure, a parallel PLC automatically takes over process control without any loss of data. Another advantage is that the robust RFID interfaces with IP67 protection can be installed directly on site in the warehouse without a protective housing.

"This is the perfect solution for us. The measured values are transmitted wirelessly and the storage boxes are identified without contact."

Joris van Dort | Manager Technische Innovationen | KWS

Wireless energy and measured value transmission

During the processing stage, a robot dynamically removes and places the seed boxes on the respective shelf space. Based on the production team's previous experience, the focus of the new solution was on contactless energy and signal transmission: "In the previous system, signals were transmitted via contact pins under the box," explains Christian Fricke, describing the initial situation. "However, contamination on the contact pins or inaccurate placement of the boxes on the pins repeatedly led to downtime in production, which is why we were looking for an improved solution."

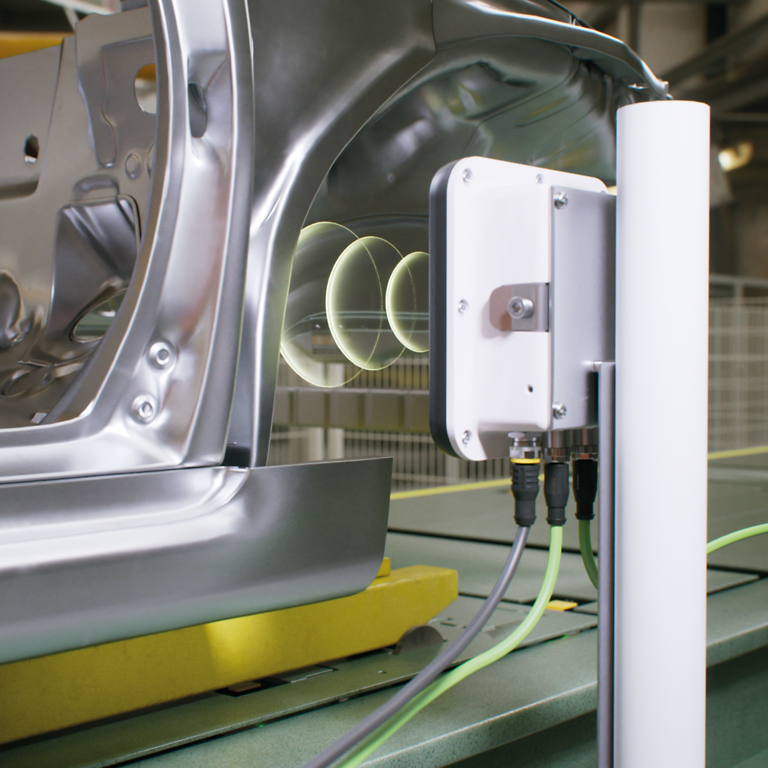

TURCK's RFID solution provides RFID tags with a connected sensor element on the underside of each box that measures the temperature inside the storage container. Each shelf space is equipped with an RFID read/write device that reads the tag on the box as soon as it is stored. In addition, the read/write device supplies the temperature sensor with energy via the voltage induced in the tag. This completely eliminates the need for maintenance for a battery-powered solution.

The fact that the TURCK solution uses the HF bus mode was a major advantage for us. This meant that we could install the RFID read/write devices on a rack level without much effort and only had to connect the pre-assembled cables with T-pieces

Christian Fricke | Team Leader Technische Innovationen | KWS

Automatic identification of seed storage boxes using RFID

The boxes are managed by the high-bay supplier's control system. At the same time, a process control system receives the booking telegrams from the control system. If, for example, a box is moved to a new position, the process control system adjusts the entries in the database. "The storage system remembers where a box has been stored," explains Christian Fricke.

RFID technology enables clear and seamless monitoring of all boxes during transport and storage. The ID stored on the RFID tag on the underside of the box can be used to check at any time whether the box is on the correct shelf space. If discrepancies occur, a warehouse reconciliation is carried out. The RFID system thus provides the basis for verifying the database information. "This is the perfect solution for us," says Dr. Joris van Dort, Technical Innovations Manager at KWS. "The measured values are transmitted wirelessly and the storage boxes are identified without contact."

Fast commissioning thanks to HF bus mode

One of the main requirements of the new system was to avoid the complex geometry of the old solution and its high cabling and wiring costs. TURCK's RFID interfaces impress with a feature that is unique on the market: the HF bus mode. This function allows up to 32 HF read/write devices to be connected per port. This significantly reduces wiring work and costs in applications with many write and/or read positions. Temperature values and IDs are read cyclically. This ensures continuous temperature monitoring. In addition, the values read out can be assigned to the containers at any time. "The fact that the TURCK solution uses the HF bus mode played right into our hands," says Christian Fricke. "This meant that we could install the RFID read/write devices on a rack level with little effort and only had to connect the pre-assembled cables with T-pieces."

Advantages of automatic addressing

The automatic addressing of RFID read/write devices is a major advantage of the TURCK solution during both commissioning and servicing. After connection to the T-pieces, the devices are automatically assigned addresses that have been activated in the web server. If a device is defective and needs to be replaced, the TBEN registers which read/write device is missing after removal. When a new module is connected, it automatically receives the address of its predecessor. This eliminates the need to store preconfigured replacement devices or to laboriously address replacement devices during servicing.

Customer| www.kws.com

Thorsten Enthöfer is Product Manager for RFID HF Systems