Control of roller conveyors

Decentralized I/O blocks decrease cycle times, shorten commissioning and reduce wiring costs

Benefits

Fast commissioning thanks to offline testing

Reduces wiring and a smaller PLC

Short response times enabled by decentralized control

Improved system performance through fast response times

Challenge

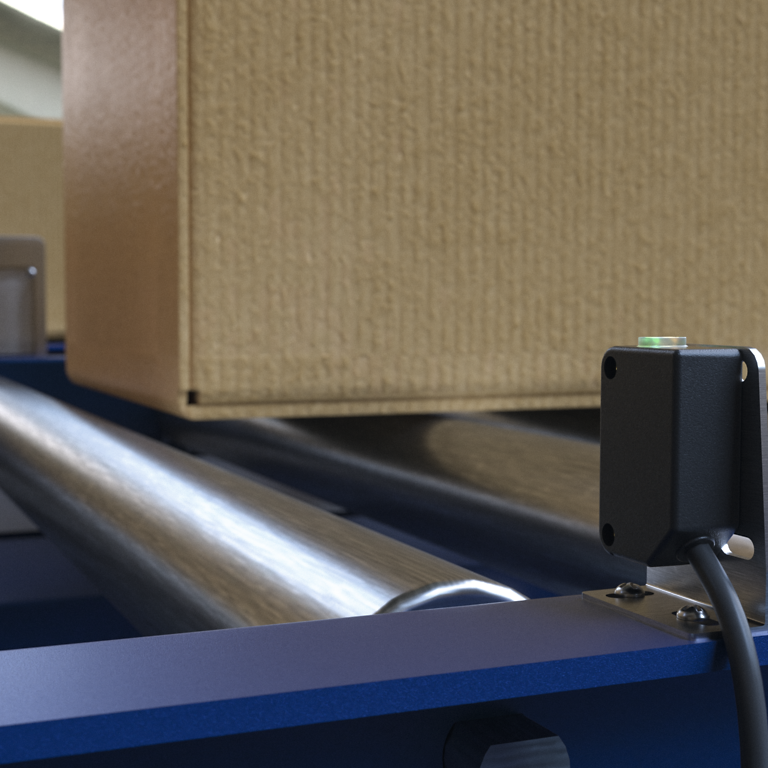

In large logistics facilities, roller conveyor modules must be controlled precisely and efficiently in order to transport cartons or reusable containers without disruption. Central control systems often result in long cycle times due to the large number of participants. This causes delays and congestion, requiring manual intervention and disrupting the flow of materials. A decentralized solution makes it possible to shorten cycle times and make the control of the conveyor modules faster and more reliable.

Solution

TURCK's decentralized I/O modules with integrated logic enable autonomous control of the conveyor modules on site. Sensors and actuators are connected directly to the IP67 I/O blocks, which offer a response time of just 2 milliseconds. Many decentralized controllers can be significantly faster than a central PLC. This prevents congestion and control errors that can occur with high cycle times. With the help of the programmable decentralized logic ARGEE, conveyor modules can be set up individually and without in-depth programming knowledge. The modules can be fully tested at the factory, which speeds up commissioning and avoids installation errors. The use of I/O hubs also significantly reduces wiring costs and lowers the cost of PLCs and installations. Thanks to IP67 protection, the modules are mounted directly on the conveyor tracks without additional protective housings.

"With the help of our decentralized I/O blocks, controlling roller conveyor segments can be made significantly more efficient and flexible."

Nitsche Frederik | Product Manager Factory Automation Systems | TURCK GmbH