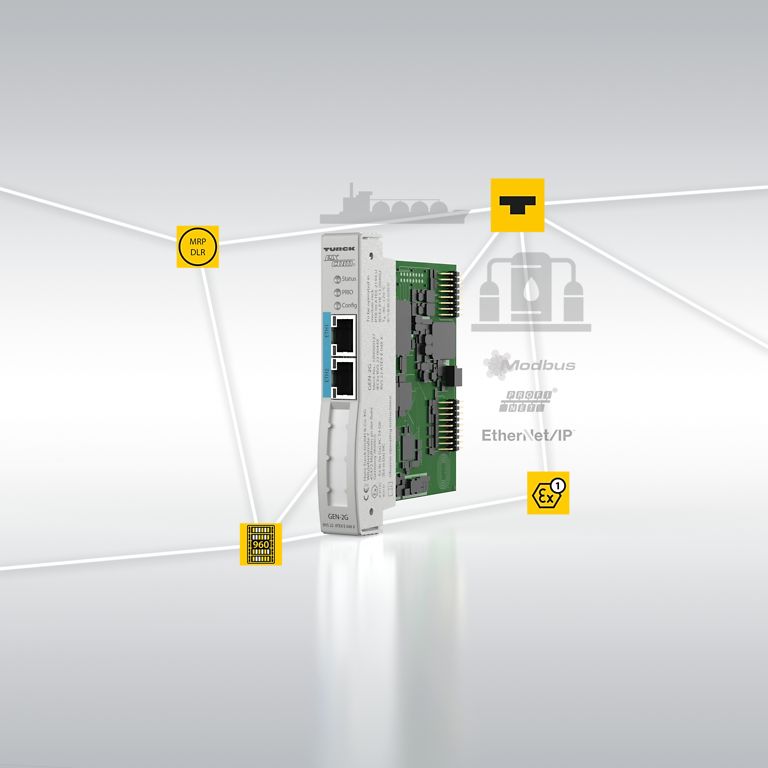

Ethernet communication for skids in Ex areas

The compact excom® I/O system is easy to combine via Ethernet gateway up to Zone 1

Benefits

Maximum packing density saves space

Ethernet enables connection to other skids and control systems

Parallel data access for in-depth process analysis and optimization

Multiprotocol Ethernet (PROFINET, Ethernet/IP, Modbus TCP) makes it suitable for use worldwide

Intrinsically safe Ethernet up to Zone 1

Challenge

Modular skids used in the process industry should be flexible to allow production capacities to be adjusted quickly. This requires a standardized, easily scalable communication interface. Point-to-point connections are often impractical because they take up a lot of space and are difficult to expand. While being compact, the solution must also have directly integrated Ex isolation for intrinsically safe signals and be easy to network via Ethernet.

Solution

The excom® I/O system with Ethernet-Gateway has been specifically optimized for use in modular skids. It enables the connection of intrinsically safe devices up to Zones 1 and 0 without the need for an additional barrier, which saves valuable space on the process modules. Its high packing density makes excom® ideal for remote installations directly on the skid. The Ethernet connectivity allows the individual modules to be quickly and flexibly networked with each other and the control system. The Ethernet gateway also enables parallel data access. The control system handles process control, and sensor data can be evaluated in external IT systems for analysis and optimization. This data is read-only for added security. The multiprotocol technology makes it possible to seamlessly integrate excom® into PROFINET, Ethernet/IP and Modbus TCP networks.

"TURCK's excom® solution enables flexible and secure networking of modular process skids via Ethernet for maximum scalability and easy integration."

Jorge Garcia | Product Manager Processautomation Systems | TURCK GmbH