Intralogistics

Automation solutions for logistics and intralogistics: digital, flexible and decentralized

Intralogistics systems never take a break. Likewise digitalization.

How can you achieve a smooth flow of materials in a digitalized supply chain?

By collaborating with a partner who provides scalable solutions to enhance the flexibility of your systems. A partner who does not tie you to a single ecosystem. A partner who understands your business and works with you worldwide to drive the automation and digitalization of your logistics processes.

Solutions for intralogistics

Discover the advantages of TURCK solutions in intralogistics systems: data-driven, digitally networked, and designed for maximum availability and smart processes.

Find your solutions

Automation solutions and products from TURCK increase the availability and efficiency of your machines and systems in numerous industries.

Insights for intralogistics

Discover relevant content for your industry, from trends and best practices to efficient automation approaches and innovative technologies that make processes more transparent, flexible, and secure.

RFID-based RTI management

With RFID-supported management of Returnable Transport Items (RTI), you always know where your material carriers or reusable containers are.

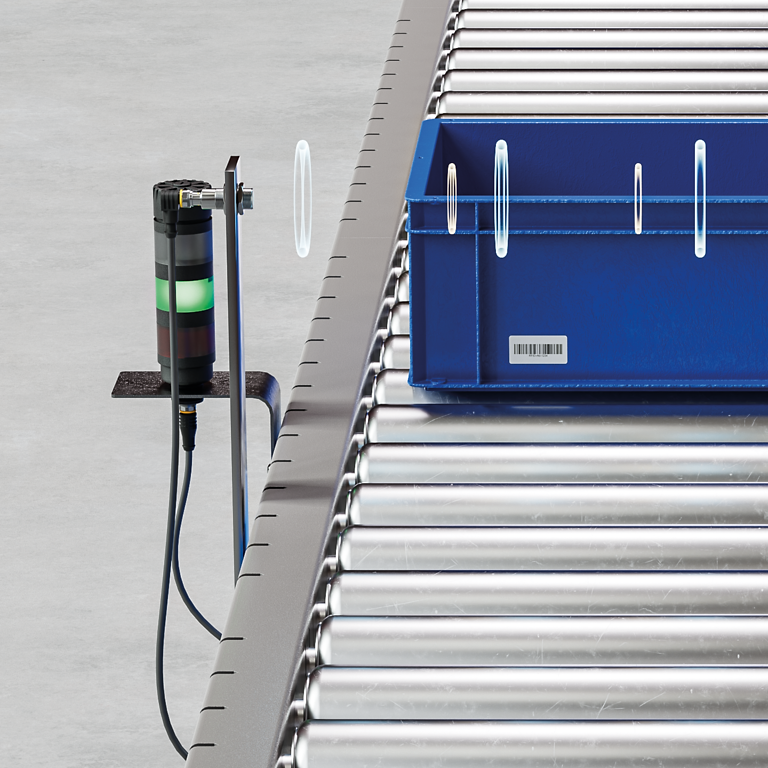

Decentralized conveying with no bottlenecks

To prevent package congestion on conveyor lines, modern conveyor technology controls packages and shipments intelligently and dynamically.

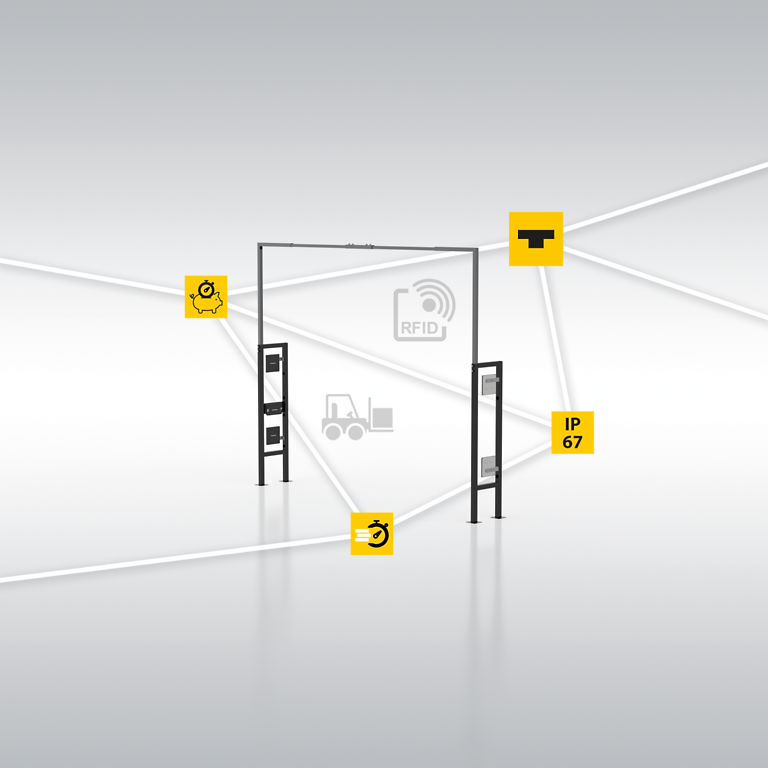

UHF RFID gates

At the interfaces of your intralogistics, RFID gates seamlessly detect products, packages and shipments — without slowing down processes.

Decentralized machine safety

Local protection of personal safety allows for short response times, high conveyor speeds and quick commissioning.

Fast turnaround times

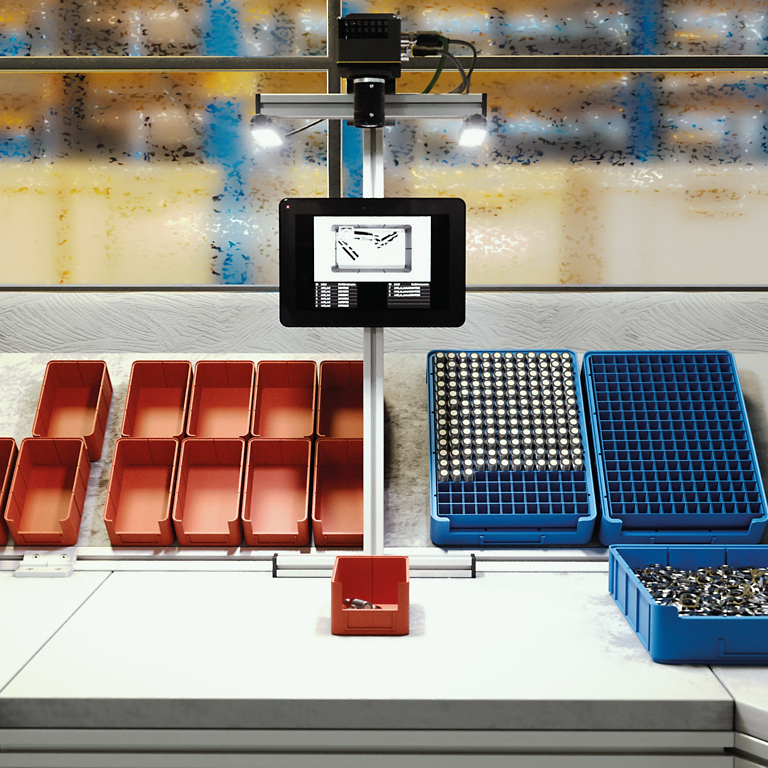

High-speed data communication, decentralized signal processing and control plus identification with RFID ensure a highly efficient flow of materials.

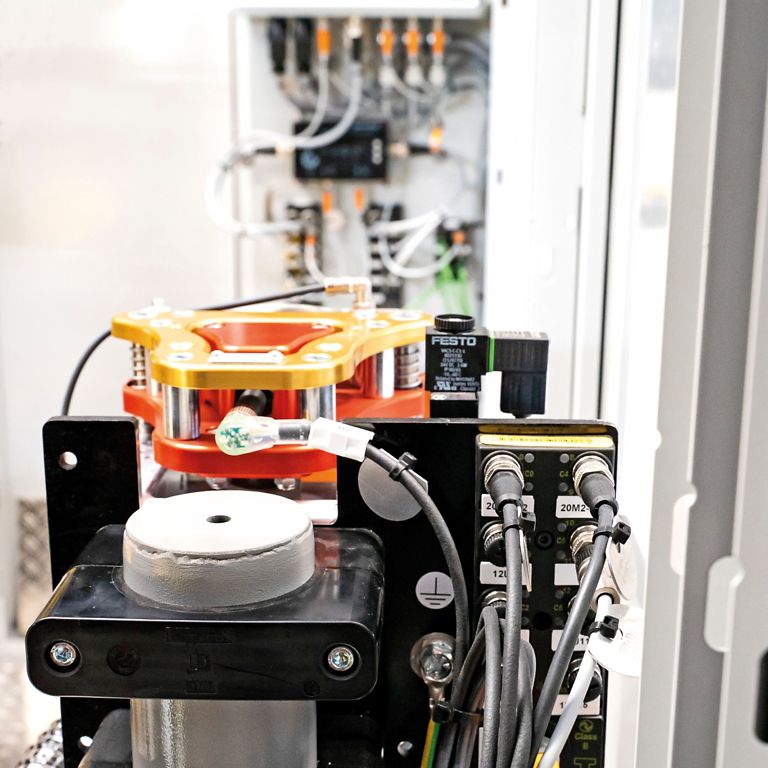

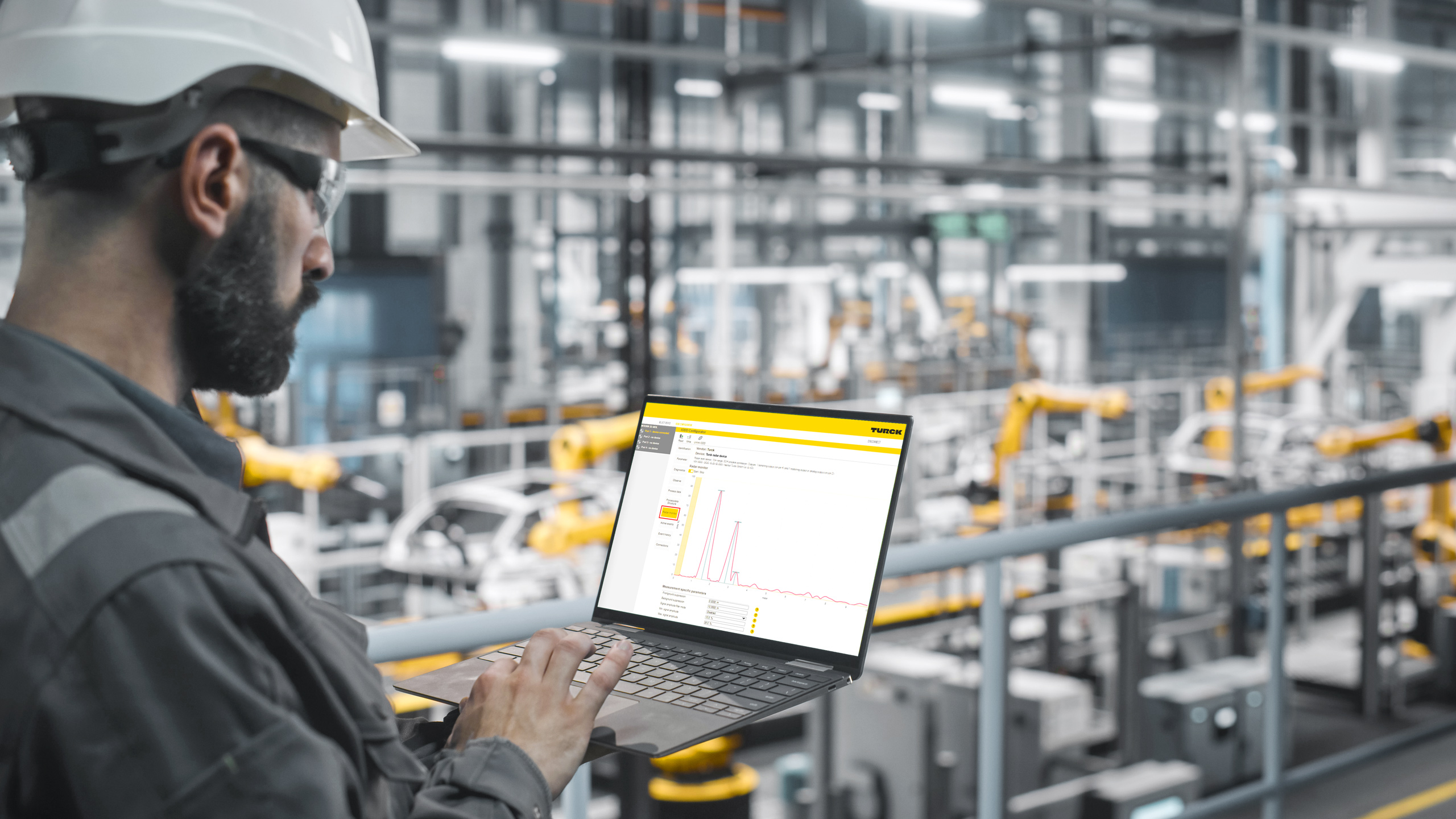

Maximum availability

Condition monitoring, predictive maintenance and robust sensor technology combined with IP67-rated I/O, control and identification technology prevent unplanned plant downtime.

End-to-end traceability

With track-and-trace systems ranging from tags to software, you have permanent access to every workpiece carrier, every product and every delivery.