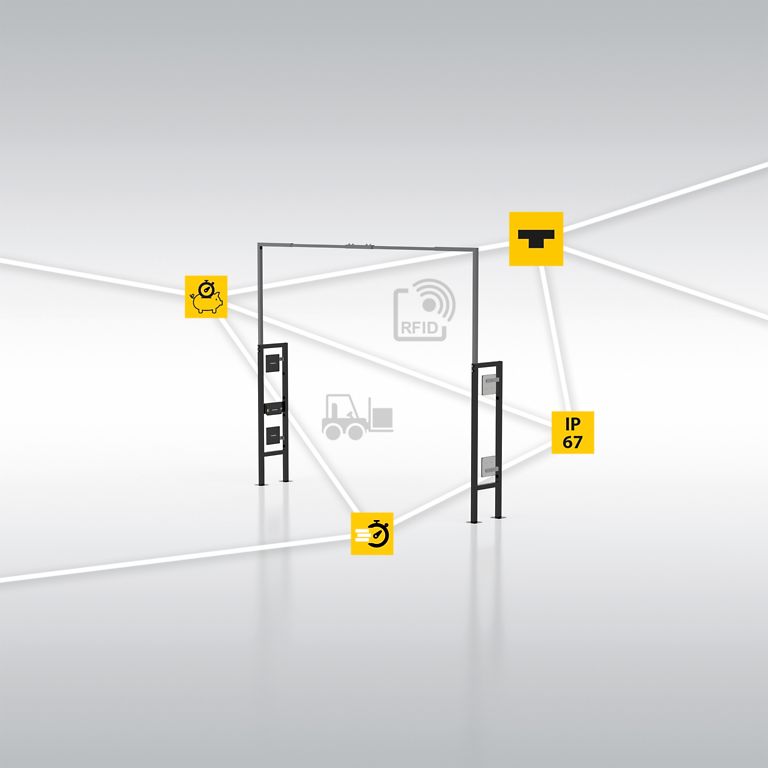

RFID in supply chains: digital supply chains ensure error-free processes, high ROI and optimum sustainability

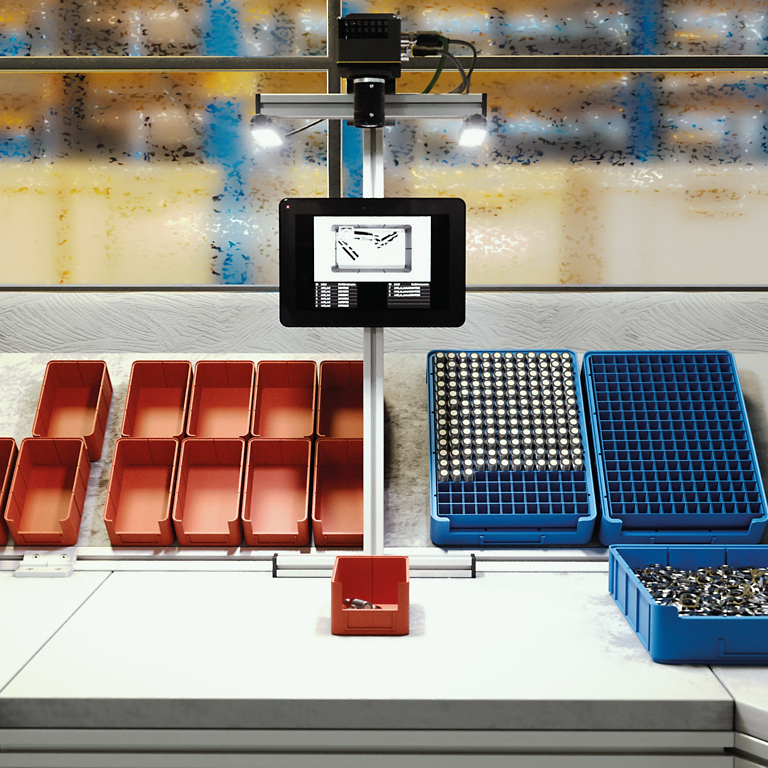

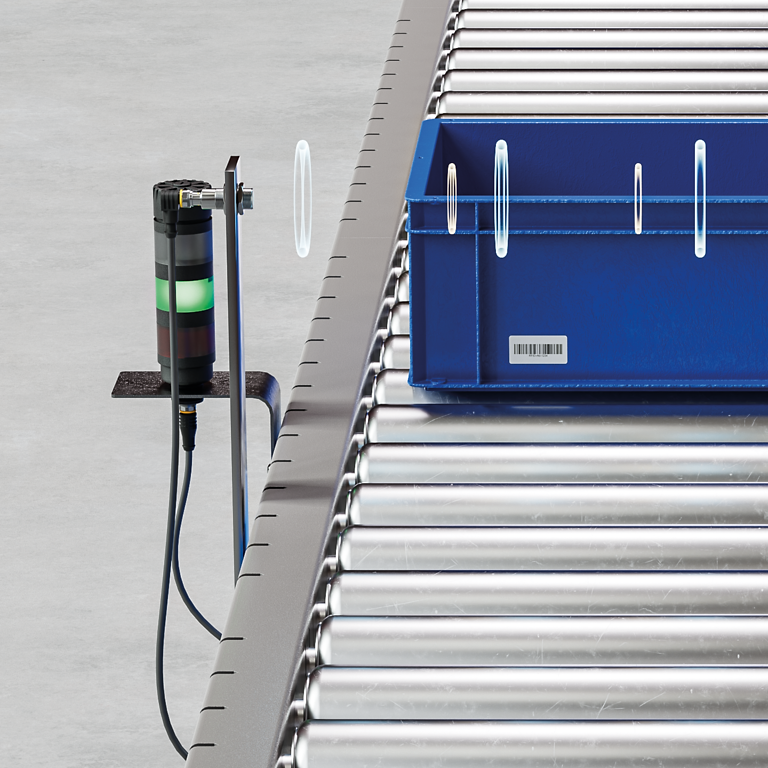

Delivery errors in non-transparent supply chains are a problem for all parties involved: the shipper must search for and have missing products subsequently delivered; the recipient must pause or reschedule processes. Logistics and transport service providers must integrate the subsequent delivery into their planning at short notice or organize additional trips. Errors often occur during picking or loading into transport vehicles. A technical solution must therefore reliably monitor both processes without delaying them.

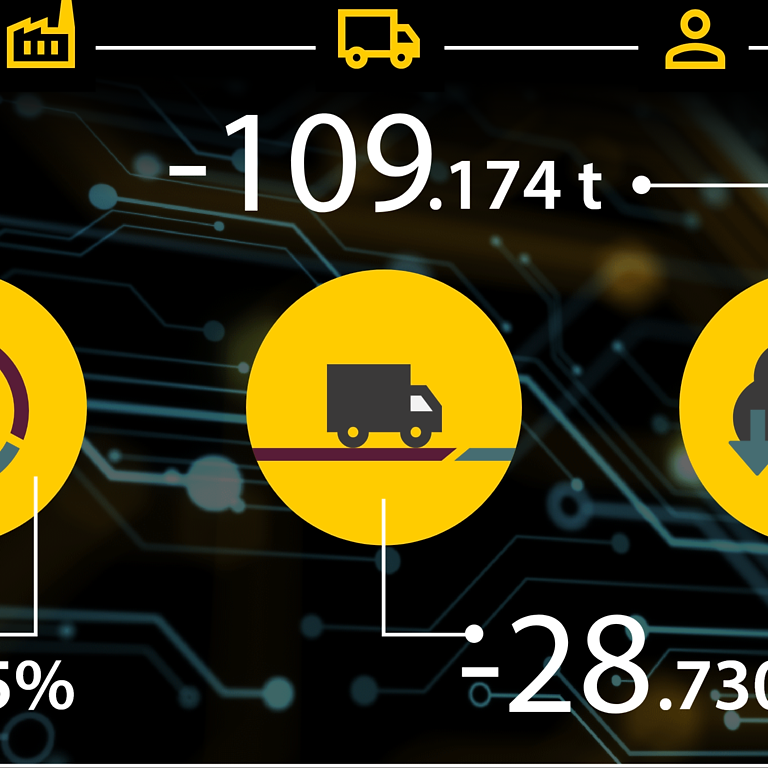

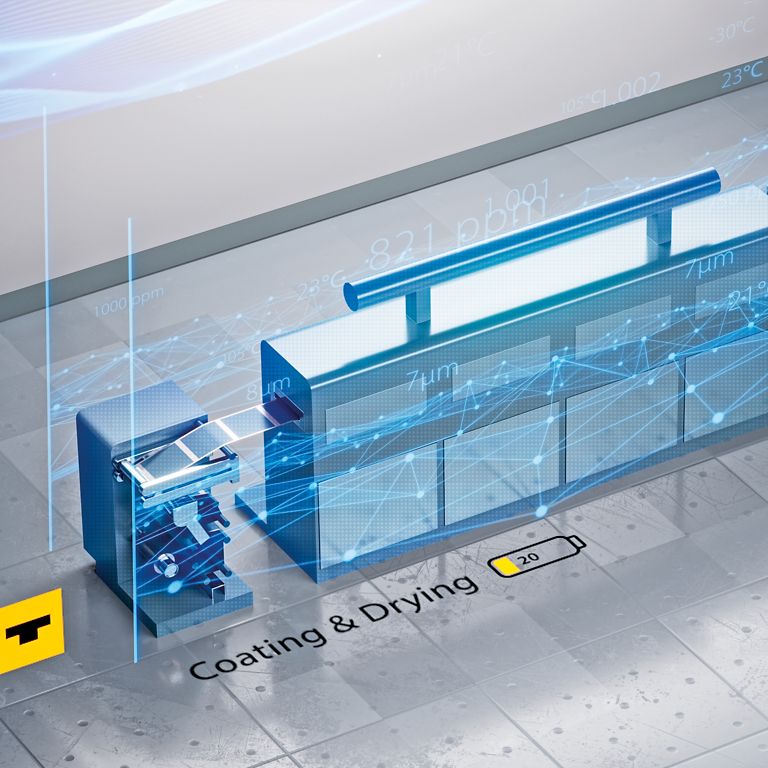

RFID technology with intelligent logistics software reliably prevents delivery errors and quickly pays off for all parties involved in the supply chain: the shipper saves on any recourse costs, searches and administrative costs. The recipient can rely on timely and error-free delivery and plan with confidence. By sending notifications, all parties involved can avoid additional trips and waiting times, which effectively reduces CO2 emissions in the supply chain and thus protects the climate and budgets.