Loading control with RFID on forklifts ensures error-free logistics

RFID solution with smart forklifts and IT integration via middleware from Turck Vilant Systems ensures reliable and fast goods flows in the Chinese automobile plant

Quick read

At the Chinese plant of a leading Japanese automobile manufacturer, the operator now automates the tracking of the logistics processes of finished parts with RFID. The new system ensures consistent transparency and thus smoother processes and more efficient operations. TURCK developed the RFID system solution based on the Turck Vilant solution for smart forklifts, which ensures greater transparency and better real-time availability of logistics data.

In order to meet the increased requirements, process optimization was required at the Chinese plant of a leading Japanese automobile manufacturer. Many processes in production and logistics of vehicle parts were still managed using paper Kanban cards and the movements of finished parts were recorded manually at nodes of the transport chain – a process that is prone to errors. The production and logistics data could not be synchronized in real time with information management systems such as WMS, MES or ERP. As a result, time-consuming and inaccurate inventory management often makes it impossible to deliver parts on time.

In order to achieve error-free and transparent logistics management, the customer now relies on RFID technology. By digitizing the information on containers and stamped parts, it was possible to automatically check finished parts in real time – across the entire process chain. The resulting transparency reduces errors and ensures more efficient operations.

Marriage of containers and finished parts

TURCK China developed a customized UHF RFID solution from Turck Vilant Systems for the customer. This system uses a passive UHF RFID tag with a unique EPC code to identify the finished part containers, which stores information such as item numbers and quantities of finished parts. The containers thus function as goods carriers in the tracking of the logistics process for the finished parts.

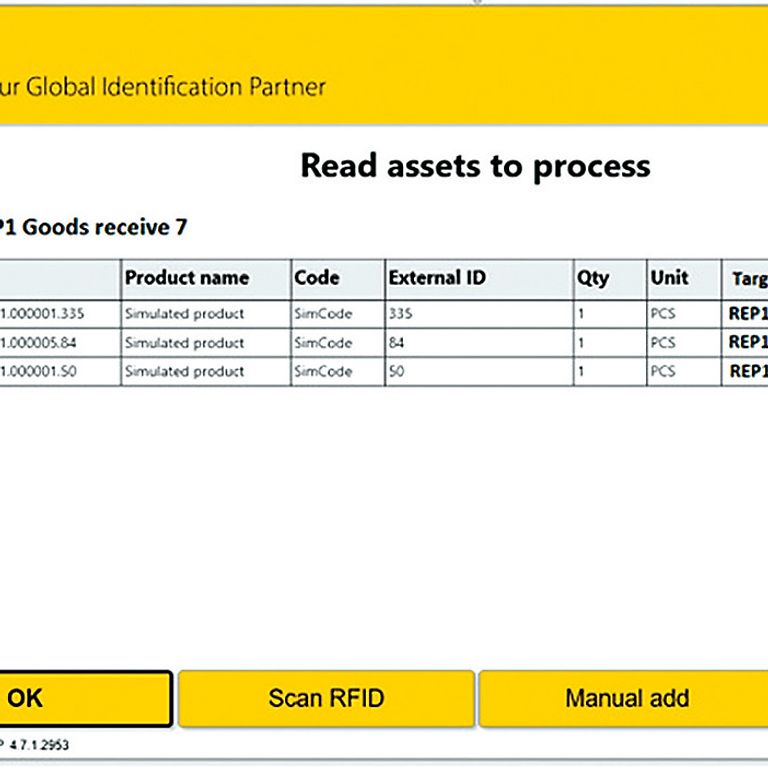

After production, the finished parts are placed in the container, both with the aid of robots and manually. A Q300 LNX RFID reader identifies the container ID. Containers and the finished parts they contain are assigned to each other in the WMS via the Turck Vilant Engine on the reader. This means that the objects can be identified quickly and reliably at all times. The containers are then transported to the warehouse using a smart forklift equipped with an RFID reader, monitor, and Turck Vilant Client. The UHF antenna on the forklift automatically identifies the container ID and updates the container and product location in the WMS as "stored."

The smart forklift is used to bring containers with finished parts into storage, to store finished parts and to transport finished parts and containers from station to station. The reliability and accuracy of the forklift is the basis of the system functionality. The advantages of the TURCK Vilant system on the forklift, such as standard data interfaces for easy connection of back-end systems, the landmark detection function for detecting the direction of movement, and the function for eliminating read errors, are indispensable.

For example, if a delivery order is received from the body shop in accordance with the production plan, the RFID forklift drives to the corresponding storage bin and picks up the container with the desired finished part. The Turck Vilant Client on the forklift detects the container and displays the current material information of the finished part on the forklift monitor. This makes it easy for the driver to check whether the order matches the requirement and avoid incorrect deliveries. Orders that have been checked for correctness are then distributed to the requesting stations according to the on-screen instructions.

Landmarks for detecting the direction of movement

The trucks with landmark detection deliver the requested materials to the corresponding stations in the body shop across several lanes. Ground location marks are arranged at the starting/entry points of the tracks in such a way that they detect the finished part outlet and the empty container inlet. The entire RFID system bridges the path between the shop floor and IT information systems, ensuring transparent information across the entire process chain. It not only improves efficiency and accuracy at the operational level, but also enables real-time tracking and planning.

Precision by eliminating read errors

The UHF RFID technology used allows multiple tags to be read simultaneously over long distances. However, as the smart RFID forklifts are used in storage areas where finished parts are stored close together, reading errors must be reliably ruled out. "Accurate detection of objects within the reading range is a major challenge for UHF RFID system applications," explains TURCK project manager Sun Zhenjun . "The reason for this is that the magnetic field range of UHF RFID is very wide and irregular. In extreme cases, several dozen tags appear simultaneously in the magnetic field of the intelligent RFID forklift. If it is unable to locate the correct target items, this leads to incorrect information and a large number of errors in delivery and dispatch, as well as incorrect inventory data."

Bridge between OT and IT

"With the introduction of the UHF RFID system, we have created information-based monitoring of the entire process for the user and automated the flow of goods,“ says Sun Zhenjun . "In particular, the RFID forklifts equipped with Turck Vilant Client are the key to success. Thanks to the landmark recognition function, they can automatically identify the correct direction for transporting goods. This means that the system does not require RFID gates, which significantly reduces the cost of setting up the system." If necessary, additional forklifts, RFID gates, E-KANBAN, and other devices can be connected to the IIoT platform Turck Vilant Visibility Manager, which connects the logistics location to the enterprise management system. As a bridge between OT and IT, it creates the basis for transparency and availability of logistics data in real time and enables high efficiency at the operational level.

Liming Hao is a Solution Design Architect at TURCK in China