Operator assistance system based on cascaded pick-to-light modules

KEB Automation has optimized four workstations with an operator assistance system for manual order picking—intuitively guided by a ready-to-connect pick- to -light solution from TURCK

Quick read

To improve quality and efficiency in manual order picking tasks, KEB Automation tested a light-guided assistance system at a packaging workstation. TURCK supplied the drive and control technology specialist with a pick- to -light solution based on the PTL110 product series from its photoelectric sensor partner, Banner Engineering. The ready-to-connect system package—comprising the power supply, connecting cables and bus-capable PTL modules such as indicators, pushbuttons and sensors—stood out for its simple installation and selective wireless communication. At its headquarters in Barntrup, KEB now uses the system at four packaging stations. The next step is to deploy it to optimize assembly operations.

System providers supply their customers with complete solution packages, from the initial concept through to implementation. Compared with a business model focused on niche components, this approach reduces dependence on other market participants—most importantly, however, end customers receive a solution consisting of products that are fully coordinated with one another. When these products are largely manufactured in-house and are available in many variants, the systems business quickly becomes a challenge for employees in assembly and logistics. Portfolio diversity is then reflected in a wide range of different work steps, along with high paper usage for orders and instructions. In addition, there is a need to train new employees, for example when positions must be filled at short notice due to vacation or illness.

This was also the experience of the medium-sized company KEB Automation, a specialist in drive and control technology with an international presence that relies on consistency across its product portfolio—whether supplying control systems, HMIs and frequency inverters for machine builders or electromagnetic systems for starting, stopping and positioning wind turbines.

Potential analysis at the Smart Factory OWL

"We're talking about several hundred device variants per workstation," explains Phillip Hannesen, project engineer in electronics manufacturing at KEB's headquarters in Barntrup. "Among them are variants that are built so rarely that a newer employee may not even be familiar with them yet." With numerous order lists and, in some cases, lengthy onboarding times, the decision gradually took shape to introduce an operator assistance system for manual tasks in production and packaging areas. A first example was found right in the neighborhood: on the demonstration platform at Smart Factory OWL in Lemgo. There, KEB engineers tested an assembly station with light-controlled, paperless operator guidance using pick-to-light. For Hannesen and his team, this marked the starting point for a pilot project that the East Westphalian company implemented together with TURCK.

"We now use around 250 PTL110 modules, and with them we can implement everything we had envisioned. They all run just like they did on day one."

Phillip Hannesen | Projektingenieur in der Elektronikfertigung | KEB Automation

Bus-capable system instead of cable clutter

A key requirement for the operator assistance system was seamless integration with the company's in-house SAP environment, since the goal was to avoid having to maintain every bill-of-materials change in two separate databases. Using its in-house expertise, KEB developed a computer-based user interface for touch monitors and then began searching for a suitable pick-to-light solution with illuminated pushbuttons or sensors. The first insight was clear: "We definitely wanted to use bus-capable components to reduce installation effort at workstations with many compartments. Otherwise, we would have ended up with a lot of cable clutter on the shelving," reports Hannesen. The market launch of the PTL110 product series from TURCK's optoelectronics partner Banner Engineering therefore came at just the right time—cascadable standalone devices featuring a multifunction display, an optional touch button, an optical sensor and an alphanumeric display. The modules communicate with one another via a Modbus-compatible protocol.

To enable simple on-site integration of the PTL devices, TURCK developed a ready-to-connect system package powered by compact IP67 switch-mode power supplies and interconnected using preassembled cables on both ends, along with connectors at defined points and Y-splitters for delivering the supply voltage. Communication with the computer is handled via an RS485-to-USB converter. Using these new technical capabilities, KEB continued to develop the operator assistance system and also involved its employees in the development process from the very beginning.

Cascading of 115 PTL modules

Before integration into more complex manufacturing areas, a packaging workstation initially served as the pilot project's test environment. During shift changes, employees there perform final assembly tasks on large units—for example, attaching housing covers or nameplates. In addition, accessories are picked from shelf bins and packed together with the unit in a single carton. To improve quality and efficiency, KEB initially installed 115 pick-to-light units. These are mounted above the shelf bins and are also used to acknowledge work steps on the monitors or to signal to the system that a carton containing the product and accessories has been placed at one of the loading stations.

In the video: operator assistance system based on cascaded pick-to-light modules

Acknowledgment via touch or optical sensor

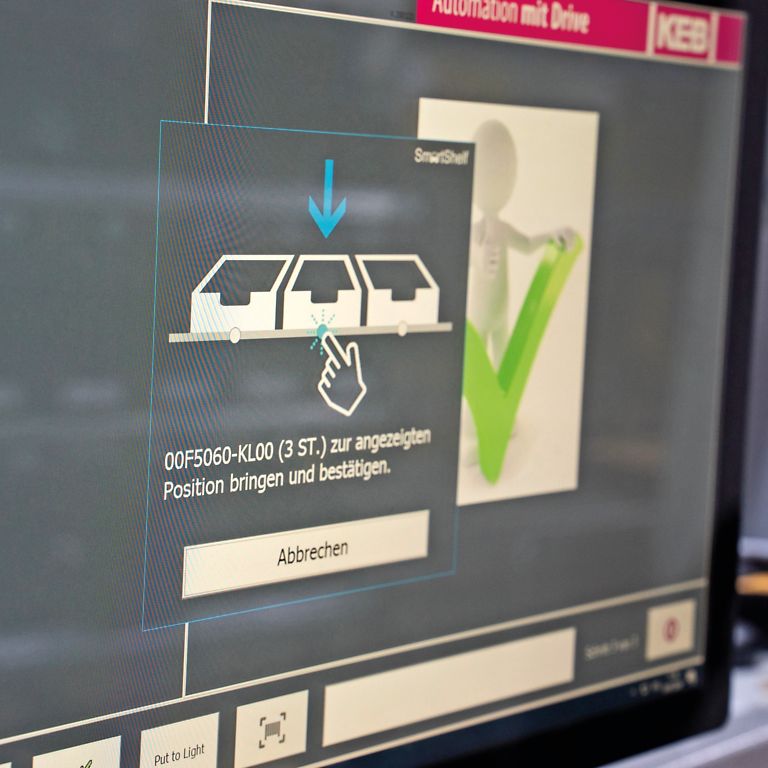

Employees start each process by scanning a device serial number. The corresponding SAP routing automatically appears on the screens; a nameplate is also printed automatically and the bill of materials is called up. While the monitors display illustrated instructions, a PTL110 module guides the operator to the corresponding pick location. In this case, it lights up green and briefly flashes yellow once the pick has been acknowledged via the capacitive pushbutton. The situation is different in the loading area, where pallets are staged on low rack frames and the PTL devices are therefore not mounted at head height. "It occurred to us that the tailgates of some cars can be opened with a foot movement," recalls Hannesen. As a result, KEB engineers selected PTL modules with contactless detection for the compressor stations. Employees now set packages down gently using both hands and simply need to hold a foot beneath the optical sensor to acknowledge the action.

Put-to-light at the short-term shelf

In the pilot project, Hannesen and KEB's tooling and equipment engineering group were less driven by ‘necessity is the mother of invention' and more by the aim of exploring the new operator assistance system's full capabilities. "That's why we deliberately chose the fully equipped version of the PTL110 devices," says Hannesen. That includes indicator lights with 14 different colors and, if required, animation functions. This proved valuable in a shelving section used to store special materials that are needed only infrequently. KEB calls this system "Smart Shelf": the computer automatically requests a material bin from the high-bay warehouse that is then made available temporarily at the packaging workstation. Employees place the bin in the designated short-term area—marked in this case by a blue light because it is a put-to light operation. The system sends an instruction once the bin is no longer required.

Wireless communication for remote areas

Especially in goods packaging, workstations can be spread out—for example due to long conveyor lines, different shelving areas or remote loading stations. In the pilot project, a forklift travel path between the core work area and additional drop-off locations for goods ready for shipment had to be crossed. Instead of laboriously cabling the PTL modules over several meters, the East Westphalian team used wireless communication via Banner's DX80 wireless system. Transmitters and receivers were installed within 30 minutes. "It was essentially plug-and-play," says Hannesen. The wireless solution has since also impressed KEB colleagues in the United States, who used it to test a mobile order picking cart with 60 pick-to-light modules. Looking ahead, wireless communication is also being considered for interaction between the operator assistance system and intralogistics industrial trucks.

Additional workstations equipped

"Packaging first, then assembly"—that was KEB's roadmap for developing the operator assistance system. Status update after a little more than a year: At the Barntrup site alone, the 1500-employee company has now equipped four packaging workstations with pick-to-light and put-to-light and has installed more than 250 PTL110 devices. The transition to two assembly stations is currently underway. "In our discussions with TURCK, we came up with many good ideas—everyone involved was highly engaged and motivated," notes Hannesen. For use in manufacturing, the operator assistance system would need to be expanded again. In addition to the PTL modules, further slave devices are to be added, including intelligent assembly units for screwing operations as well as cameras that check whether components or cables are in the correct position.

Customer | www.keb-automation.com

Author | Patrick Flatt is a sales engineer at TURCK