Key technology for digitalization

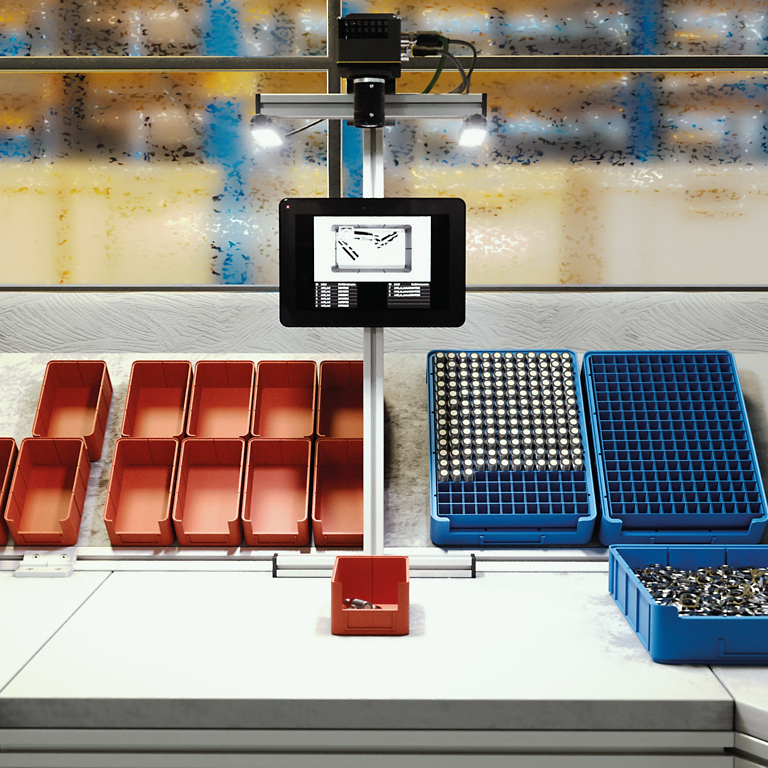

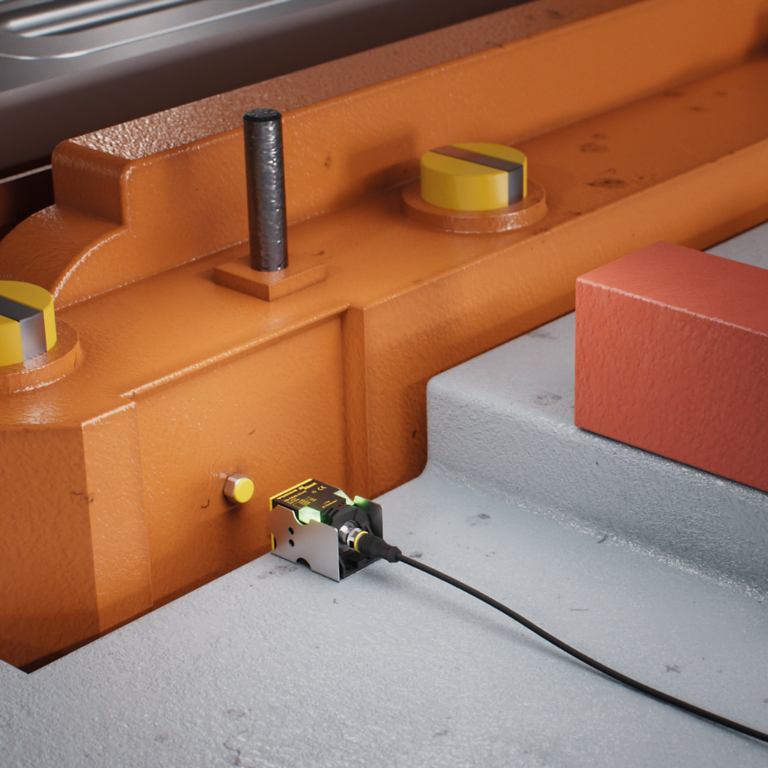

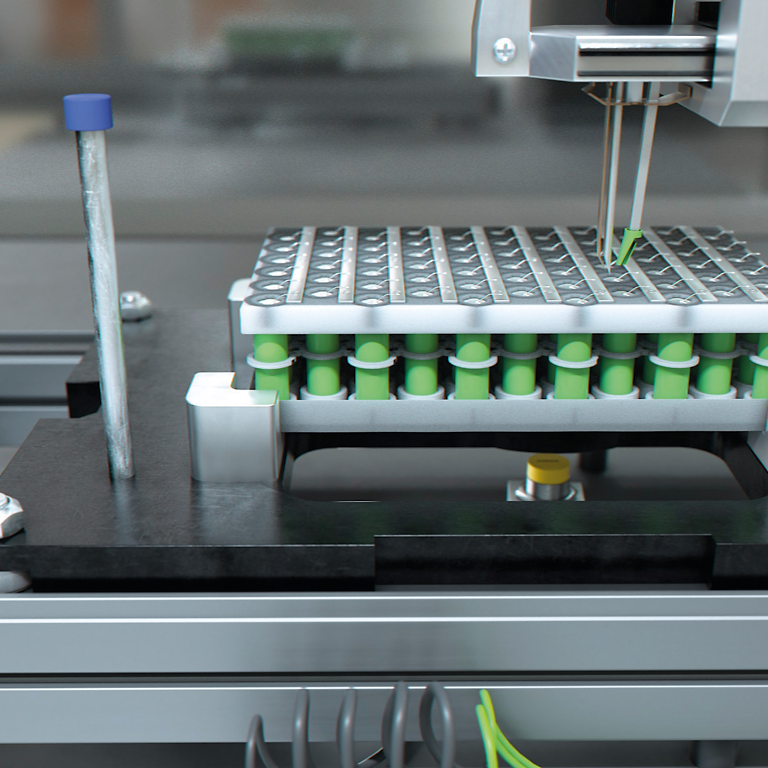

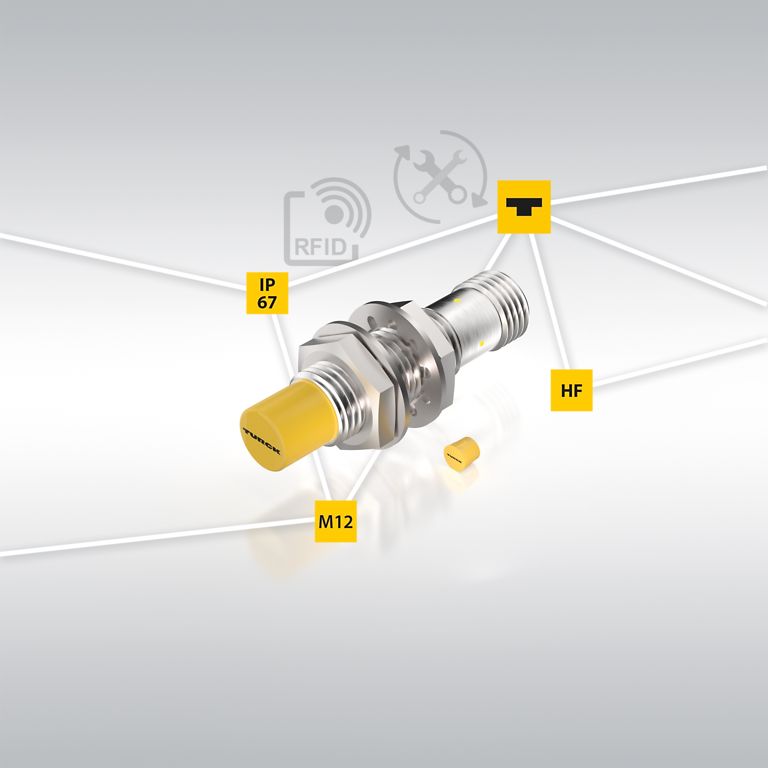

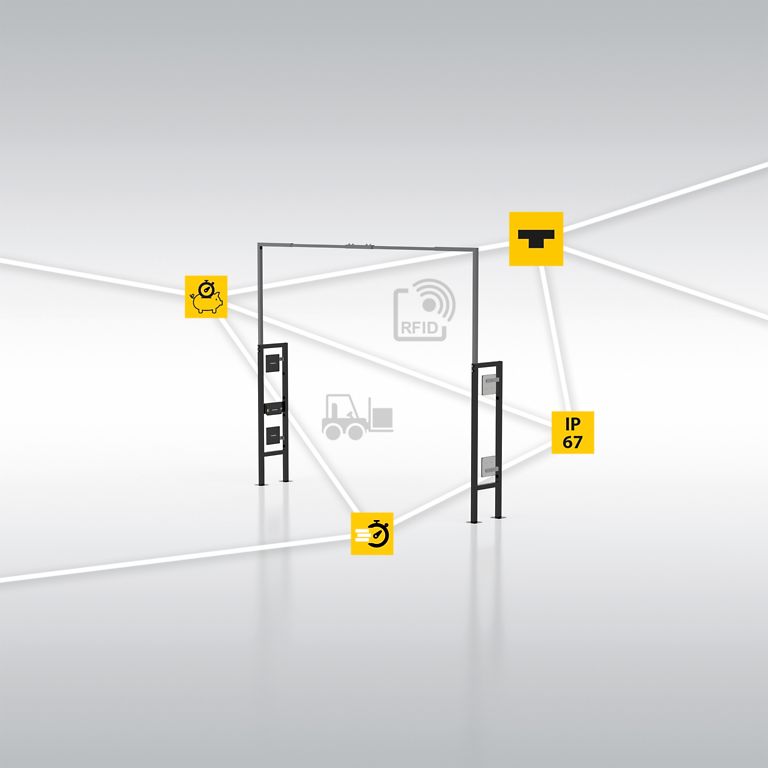

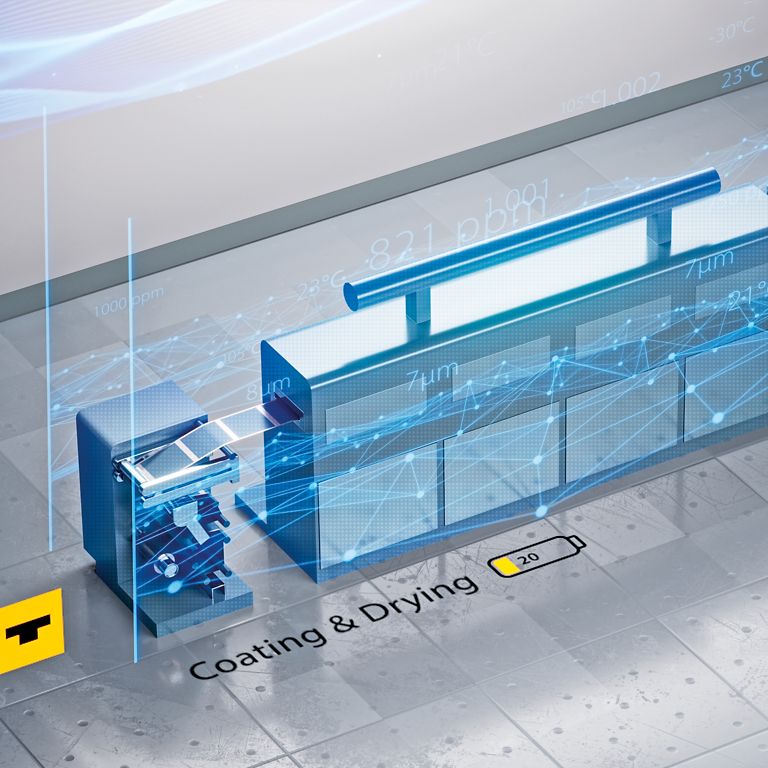

IIoT, the Industrial Internet of Things, requires the use of intelligent industrial components that allow physical objects in production logistics to be present over the Internet. Regardless of whether these are containers with raw materials, components, preliminary products or finished products — equipped with RFID tags, all components can communicate with each other as smart objects in the network. This makes RFID a key technology of the IIoT.

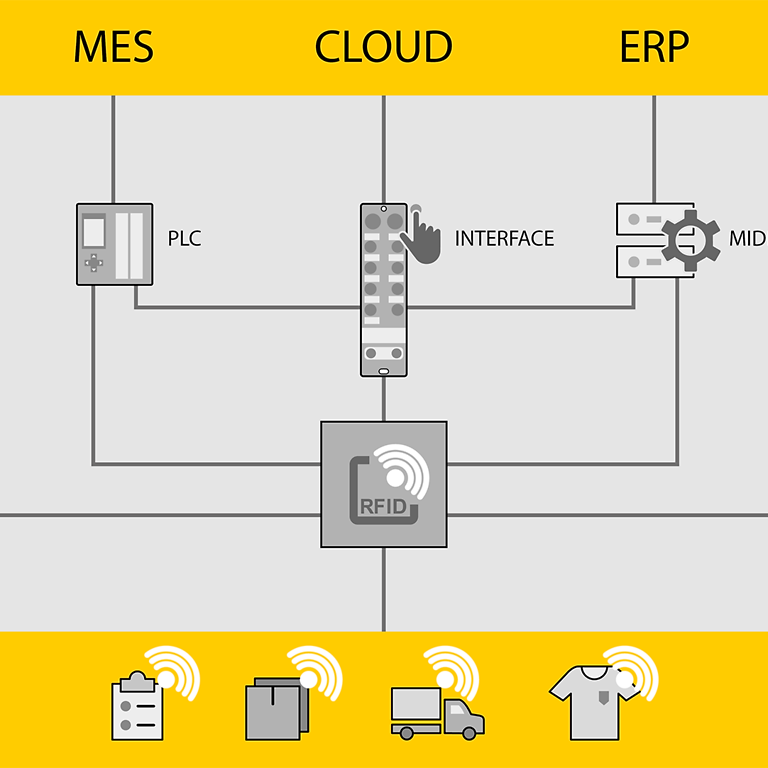

Information generation in a suitable context

The information of each Smart Object is obtained via strategically placed reading points. Depending on the application, they are forwarded directly to higher-level systems such as an ERP, or they are transferred via an interface to the PLC or the Turck Vilant Middleware. In this way, Turck's system solution brings the data of the Smart Objects to the level of enterprise applications and plant automation systems. Here, relevant information for your processes and decisions is generated in a suitable context.