Error-free tool identification in metal presses

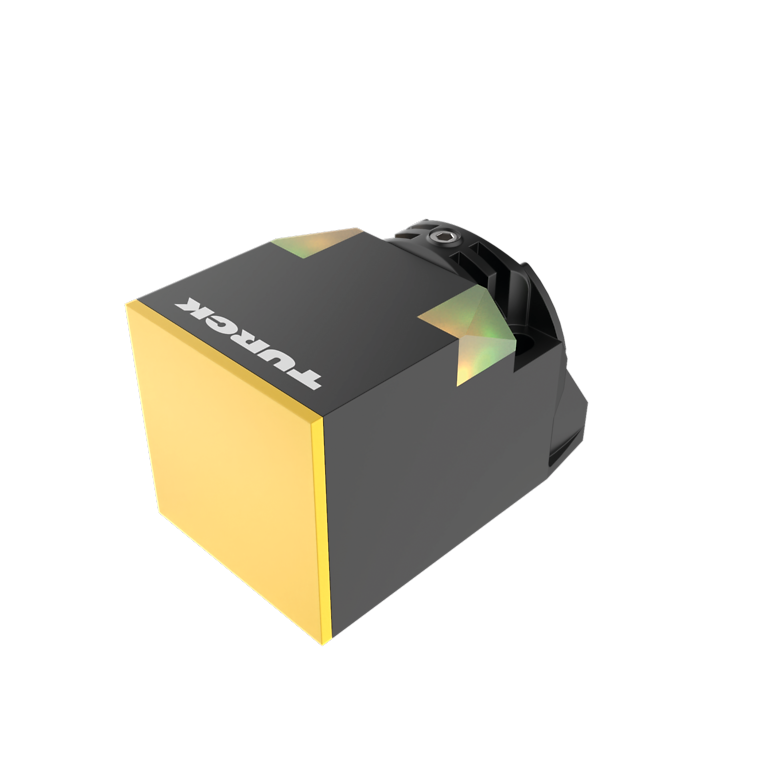

The RFID system BL ident and inductive proximity switches ensure tools can be changed and pressing processes can be carried out in sheet metal presses

Benefits

- The RFID system BL ident prevents production downtimes by uniquely identifying the correct press tools

- Inductive sensors check the presence and correct positioning of the inserted sheet metal

- This eliminates crashes and downtimes

Challenge

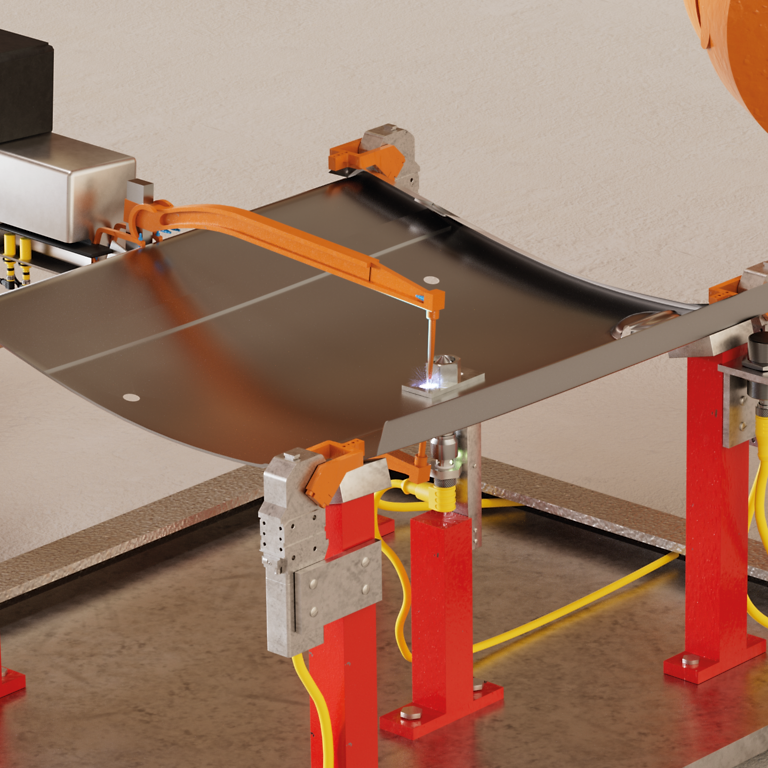

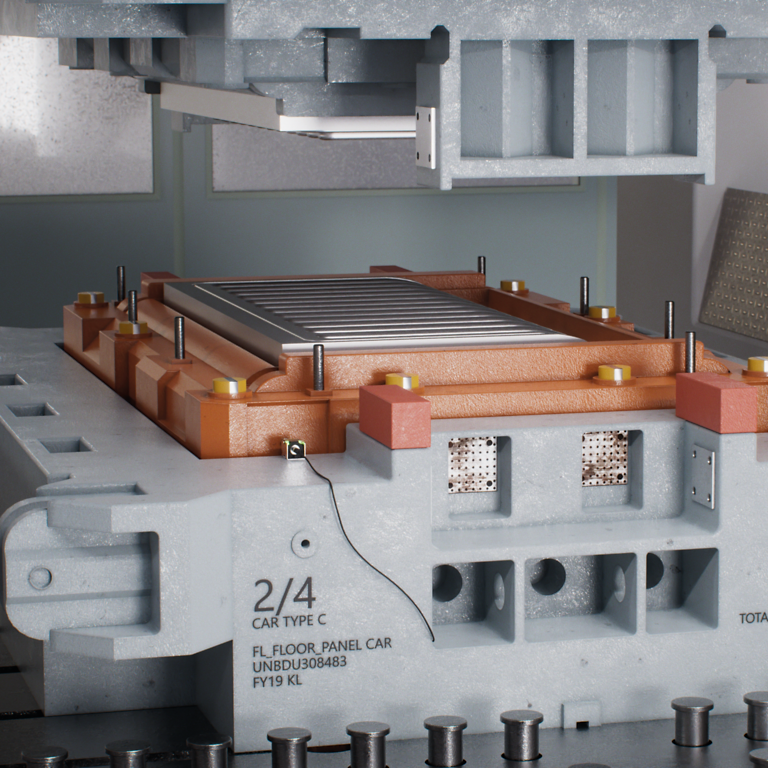

In metal processing, large metal presses must always have the correct tools inserted to ensure error-free production. Incorrect tool assignment can lead to scrap, machine damage and long periods of downtime. At the same time, it must be ensured that the sheet is precisely aligned before the pressing process starts. A reliable, automated solution for tool verification and checking the position of metal sheets is required.

Solution

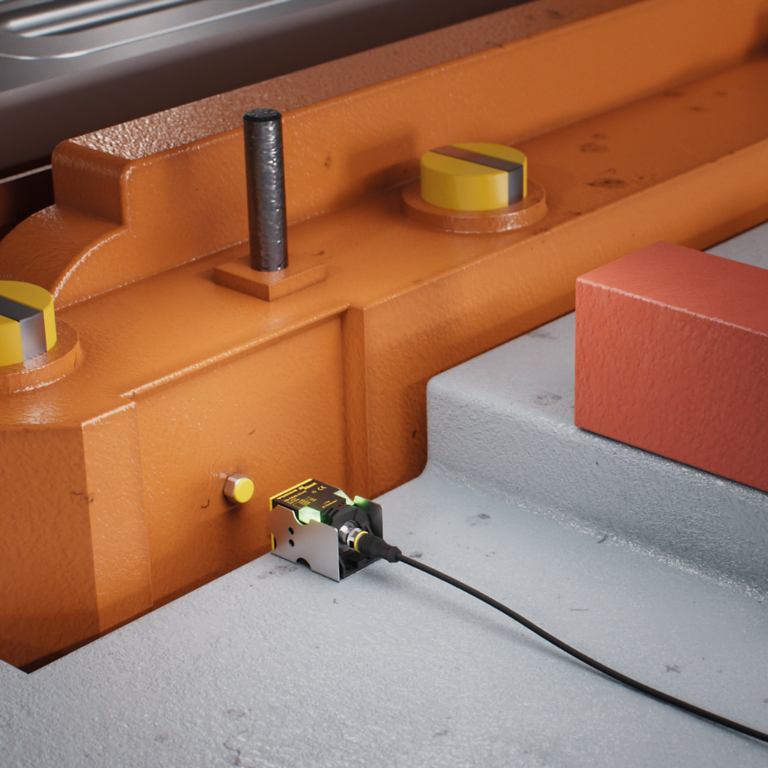

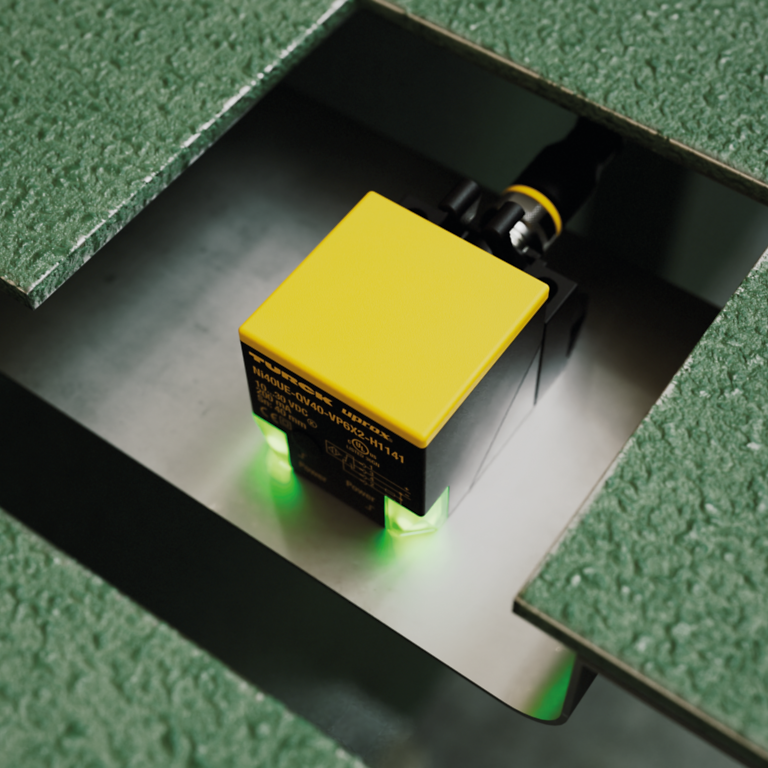

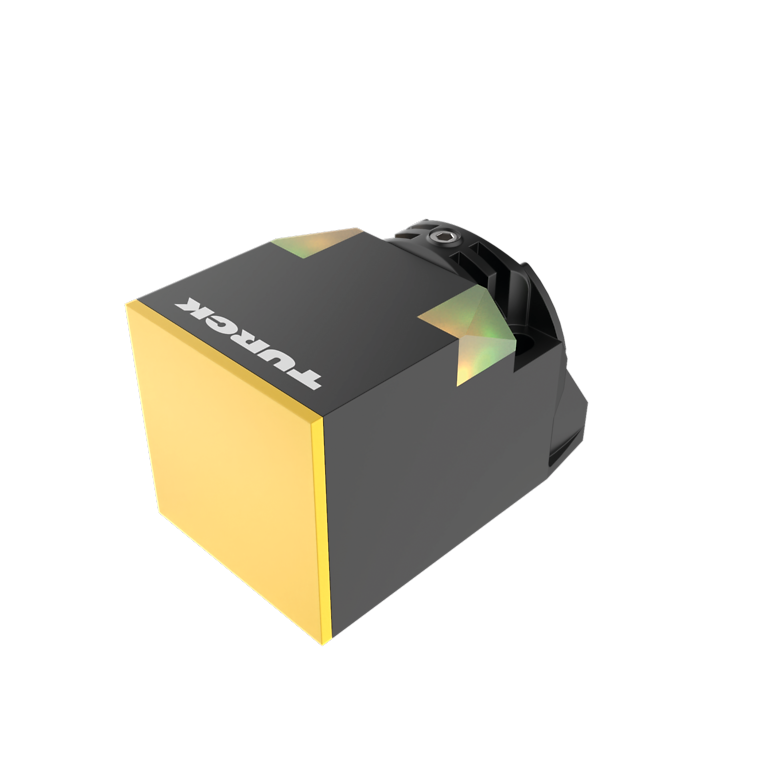

TURCK's BL RFID system enables error-free tool identification by ensuring that the correct pressing tool is always used. Each tool set is equipped with an RFID tag that is automatically read as soon as the tool is installed in the press. This prevents the use of incorrect or defective tools, avoiding scrap and machine damage.

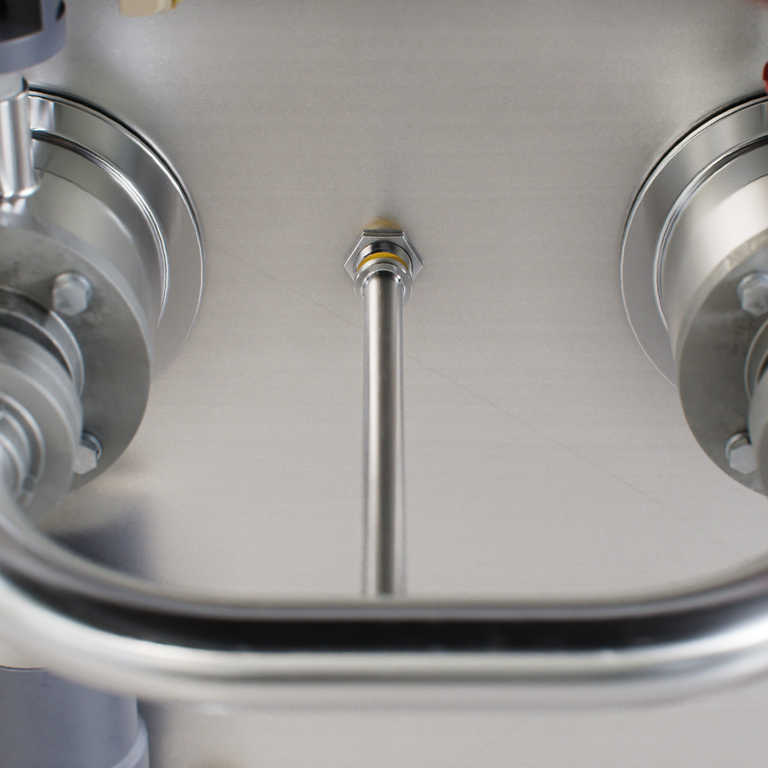

In addition, TURCK's inductive proximity switches are used to check the exact position of the raw metal sheets. These sensors are specially designed for use in metallic environments and are not sensitive to strong magnetic fields, which often occur in press shops. Thanks to their high switching distances, they reliably detect whether the sheet has been inserted correctly before the press is activated.

The combination of RFID tool identification and proximity sensors significantly increases process reliability and reduces unplanned downtime. Both systems can be integrated into the same TURCK I/O solutions, which simplifies installation and enables seamless communication. This makes production more efficient and economical.

"The combination of RFID and inductive proximity sensors ensures maximum process reliability and avoids costly downtimes."

Thorsten Enthöfer | Product Manager RFID HF Systems | TURCK GmbH

Erfahren Sie mehr über unsere Produkte