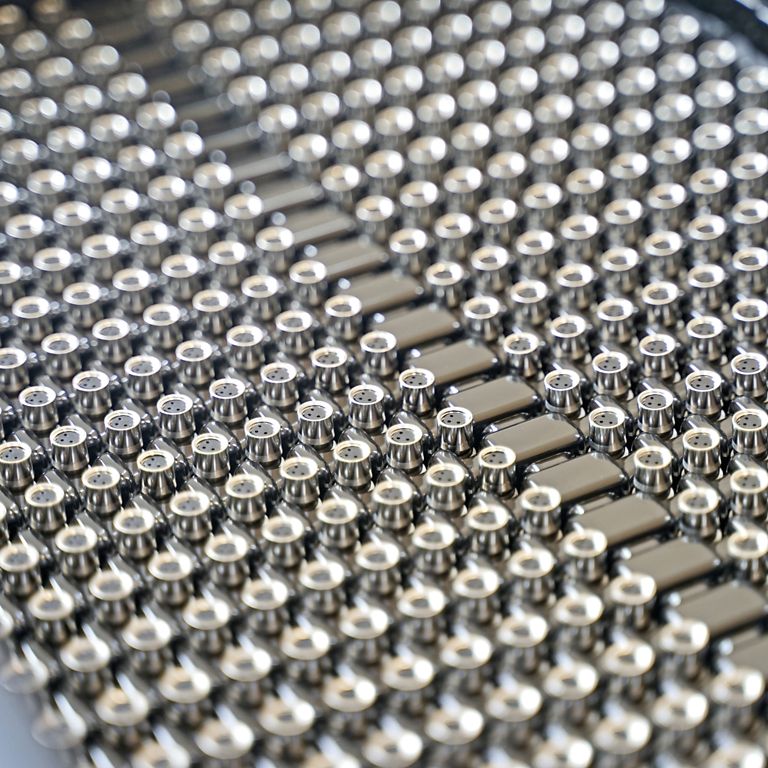

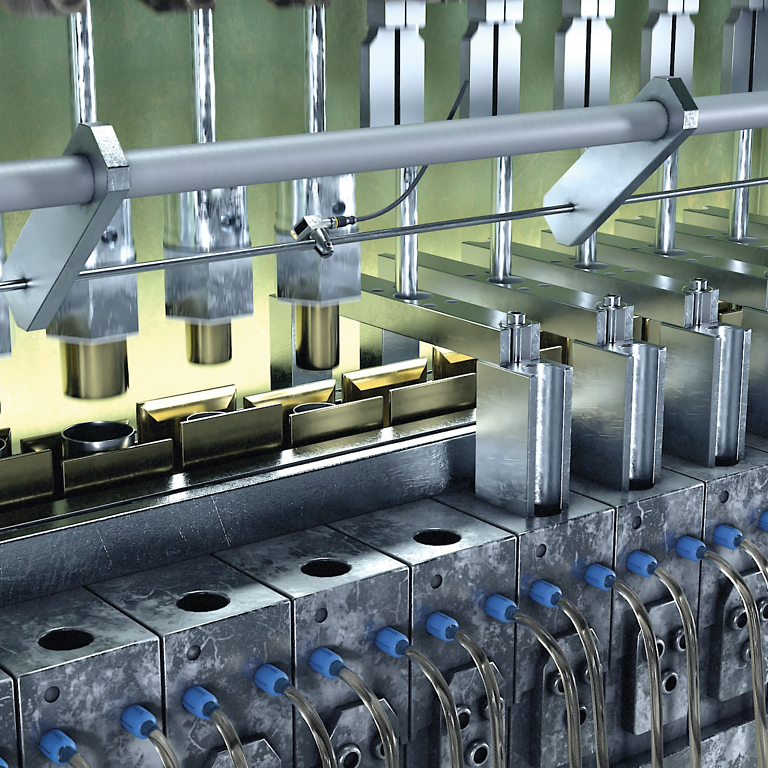

Detection of metal cylinders

Distributed signal processing on the I/O module enables fault detection within 10 milliseconds, even at the highest process speeds

Benefits

Distributed signal processing within 10 milliseconds for high process speeds

Improved system availability as machine damage is avoided

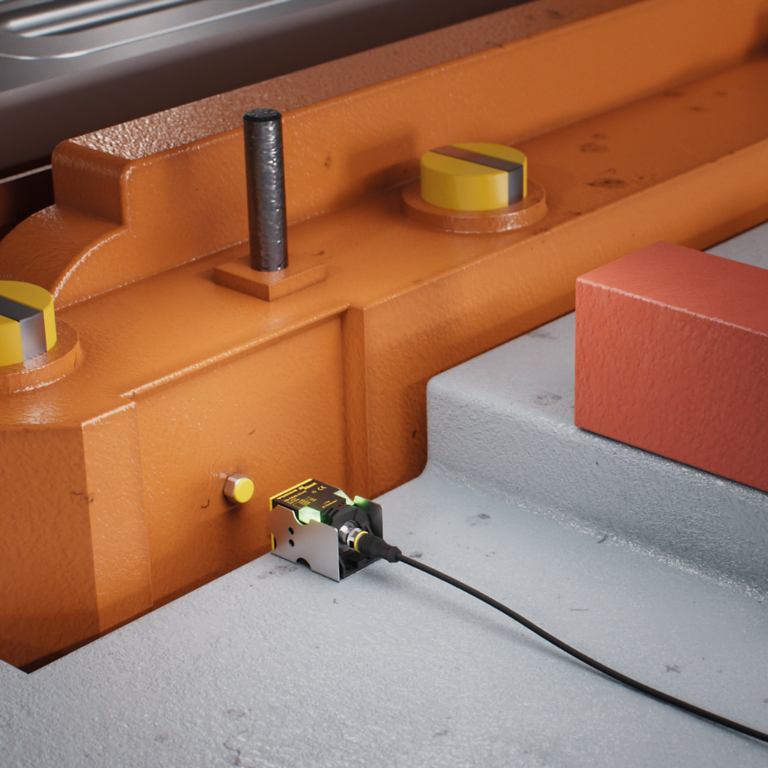

Minimal wiring effort thanks to IP67 IO-Link master

Plug-and-play sensor replacement as sensor parameters are stored in the IO-Link master

Challenge

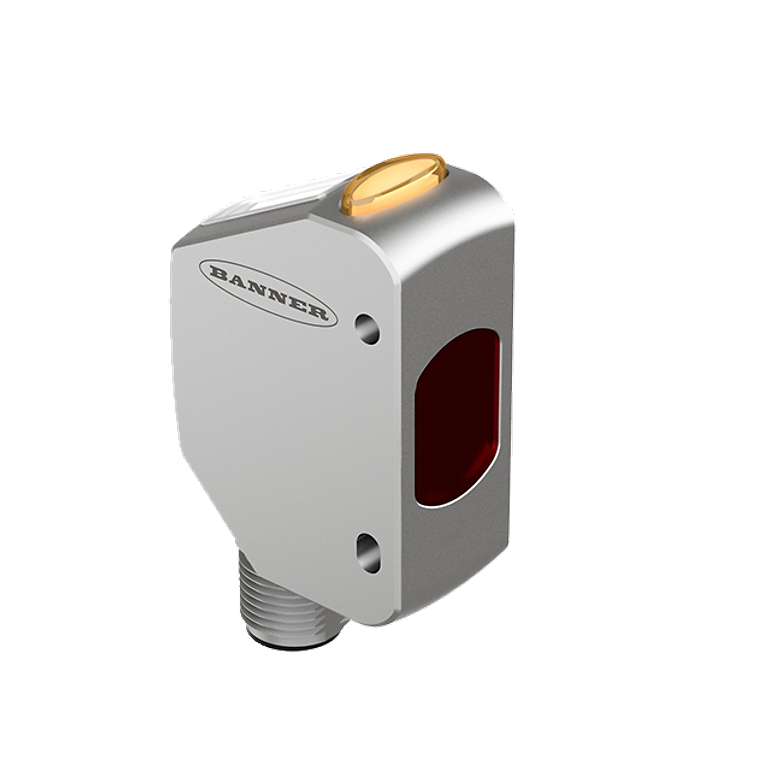

The detection of shiny sheet-metal cylinders in presses for battery production poses challenges for optical sensors — especially at high process speeds. Mechanical sensors often require intensive maintenance and are prone to malfunctions. The Q4X laser sensor from Banner reliably detects shiny objects. Decentralized signal processing on the IO-Link master TBEN-S enables error detection in just 10 milliseconds, effectively preventing machine damage.

Solution

The Q4X laser sensor from TURCK's photoelectric-sensor partner Banner Engineering detects shiny sheet metal-cylinders in just 10 milliseconds. This is essential to prevent costly machine damage in battery production. To enable the high process speeds, the sensor signals are processed decentrally on the IO-Link master TBEN-S. Three to four Q4X sensors are connected to a master that adds up the signals. In the event of an incorrect checksum, the controller immediately stops the process. Parameterization is simple via Turck's web-based ARGEE tool in the flowchart, without programming. In addition, IO-Link simplifies the sensor change: The parameters are stored in the master, so that a replacement sensor is ready for use immediately. The robust IP67 design allows the I/O module to be mounted directly in the machine, minimizing cabling overhead. As a multi-protocol device it can be flexibly integrated into Profinet or Modbus TCP networks.

"The combination of the Q4X laser sensor and the TBEN-S IO-Link master ensures fast and reliable detection of metal cylinders — a decisive advantage for highly dynamic production processes."

Markus Bregulla | Director Product Management Banner Products | TURCK GmbH

Learn more about our products