Reliable AGV control enabled by a sensor-based, end-to-end solution

Proferro optimizes production and logistics efficiency as well as safety with automated guided vehicles—controlled around the clock by TURCK's sensor-based, end-to-end solution

Quick read

As one of the leading specialists in high-precision metal castings, Proferro supplies OEM manufacturers worldwide across a wide range of market segments, including agricultural machinery, construction equipment, compressors, textile machinery, and general mechanical engineering. To improve employee ergonomics and safety and to make production and logistics processes more efficient, the Belgian company has introduced a fleet of automated guided vehicles (AGVs). Turck Multiprox developed a sensor-based, end-to-end solution for autonomous and reliable control of the AGVs around the clock

With more than 80 years of experience, Proferro NV is one of the leading specialists in metal processing. Headquartered in Ypres, Belgium, the company manufactures custom castings and provides a comprehensive range of services, including cast iron production, machining, assembly and co-engineering for manufacturers of agricultural machinery or mining equipment, compressors, textile machinery and other industrial applications. With a strong focus on quality and innovation, Proferro is regarded as a reliable, long-term partner and a global supplier to OEMs. An extensive machine park—comprising more than 100 CNC-controlled machines—and a dedicated workforce of approximately 600 employees form the foundation of the company's success. Smart automation is a central element of its production operations.

To improve employee safety and ergonomics and to increase the efficiency of production and logistics processes, the company planned to introduce a fleet of automated guided vehicles (AGVs). These AGVs were intended to replace the previously used gas-powered forklifts. Forklift operators repeatedly had to search for the correct parts in the warehouse and perform extensive manual scanning, which often led to errors and delays. The AGVs are now intended to automate the inbound and outbound transport of castings to CNC machines and to operate as autonomously as possible to eliminate lost time and errors caused by manual activities.

"Two key elements were critical to the successful implementation of this solution: the software, which reduces complexity and enables easy monitoring, and the reliability of the sensors. Our experience to date has shown that TURCK components deliver exceptional reliability and require no maintenance at all. This makes them an extremely cost-effective and robust solution—exactly what we were looking for."

Mathieu van Den Berghe | Transformationsmanager | Proferro

Robust solution for dusty environments

One of the key challenges was the reliable control of the vehicle fleet, particularly within the dusty production environment of a metalworking company, which requires an especially robust solution. In addition to reliable sensor technology, a rugged system is required to capture, secure and transmit data to higher-level systems. "Our goal was an automated logistics solution that enables just-in-time delivery of parts to the machines in the adjacent production facility," explains Mathieu van den Berghe, . "A fully automated high-bay warehouse already ensures that the required parts are made available at the pickup stations. However, the production area itself has always been a particularly challenging environment due to dust and dirt exposure." A system for sensor-based data acquisition and wireless transmission would need to overcome these challenges and ensure the long-term, smooth operation of the automated guided vehicles.

Since an RFID system with vision cameras proved to be too costly due to the large number of parts, TURCK proposed an integrated solution using ultrasonic and photoelectric sensors, along with robust I/O modules, switches and an IIoT gateway. "The Turck Multiprox team quickly made it clear to us that sensors alone would not be sufficient. Although they can reliably detect signals, a complete solution is required to correctly transmit the data to the target software for AGV control," explains van den Berghe.

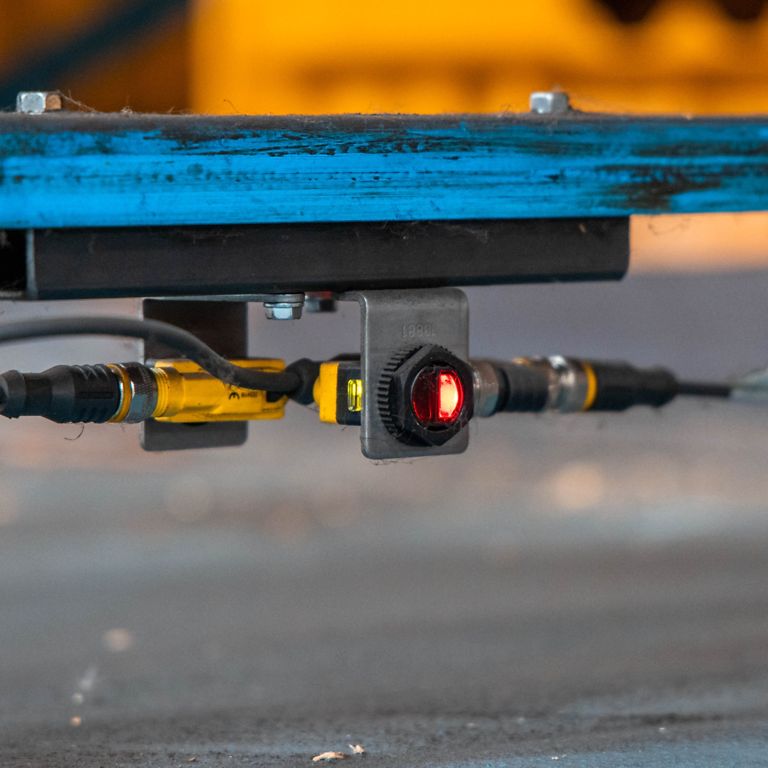

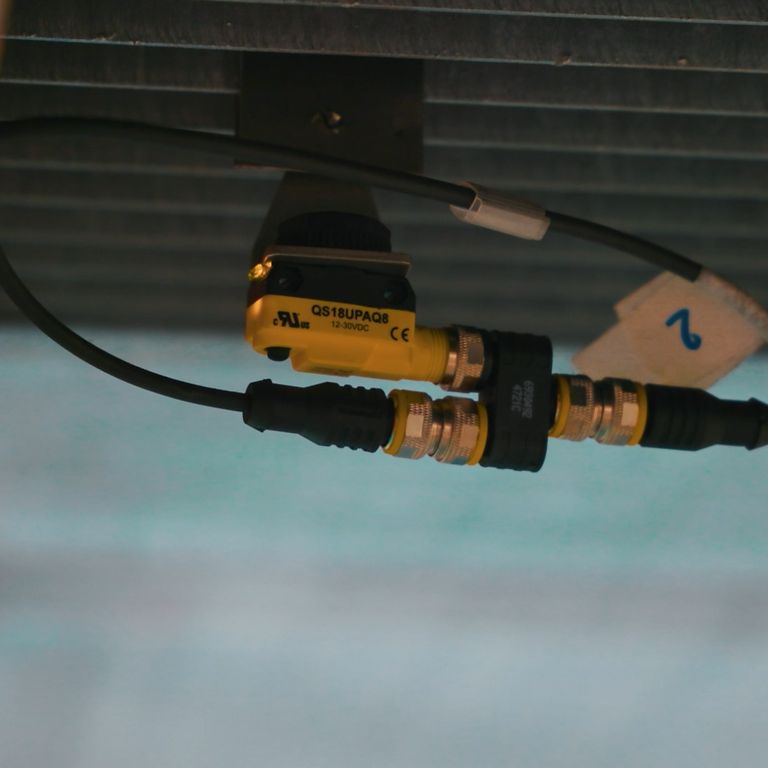

The proposed end-to-end solution impressed the user with its simplicity and robustness. It is based on retroreflective photoelectric sensors, QS18UPAQ8 ultrasonic retroreflective sensors with switching output and retroreflective laser sensors with adjustable background suppression. Mounting the ultrasonic sensors beneath the shelving proved particularly effective, as this prevented dust accumulation. In addition, photoelectric sensors and laser sensors are used to detect pallets on the floor.

Real-time data transmission and flexibility through TURCK multiprotocol technology

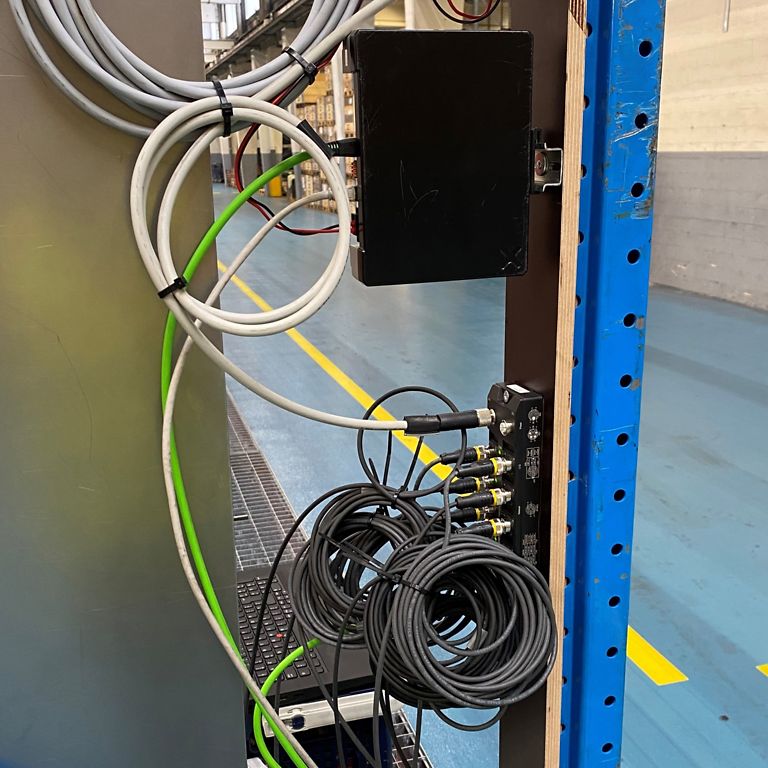

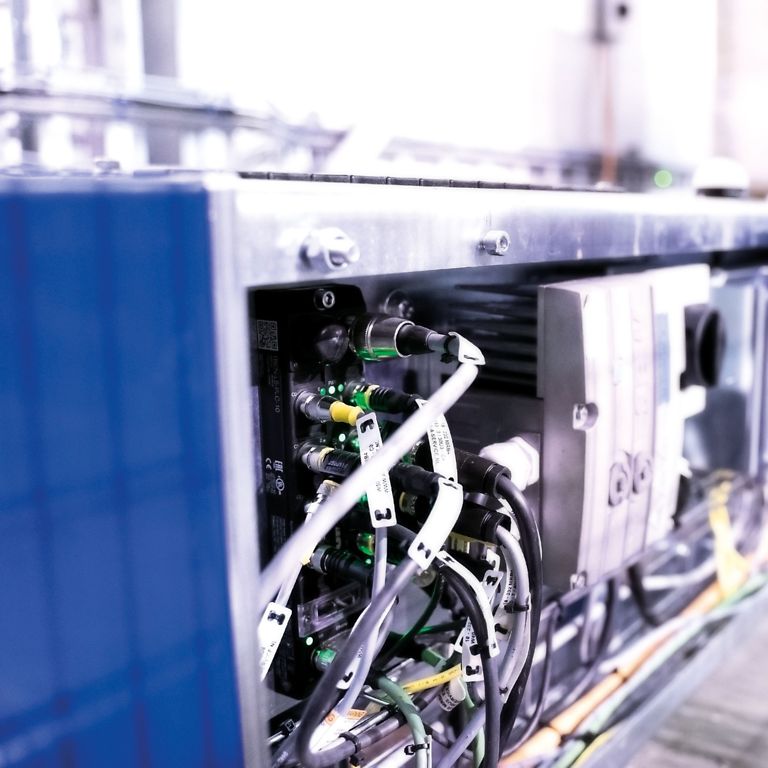

The sensors reliably detect whether a pallet is present and continuously transmit this information to the TBEN-LL-16DXP, the heart of the system. This compact block I/O module features 16 universal digital channels that can be configured as inputs or outputs. It aggregates the sensor data and transmits it to the controller in real time. With its IP67 rating, the module is protected against water and dust, allowing for field installation without an additional control cabinet. This makes it particularly well suited for the intended use in the demanding production environment of a metalworking application, where reliability and durability are critical.

Another key advantage of the block I/O modules is the TURCK multiprotocol concept. This allows the modules to automatically adapt—without any user intervention—to the Ethernet protocol used in the network, whether Ethernet/IP, Profinet or Modbus TCP. As a result, they can be flexibly deployed in a wide range of systems without complex modifications. This versatility not only simplifies integration into existing infrastructures, but also makes TURCK's end-to-end solution future-proof by ensuring compatibility with a broad variety of systems.

Robust network infrastructure and efficient data transmission

To create a robust network infrastructure, TURCK supplied industrial managed Ethernet switches of the TBEN-L5-SE-M2 type. The compact 10-port switches with a Gigabit high-speed backbone ensure short cycle times and reliable operation at the highest IIoT data rates. The high-speed link-up function supports fast tool changes in less than 150 ms, enabling extremely short cycle times. Thanks to the option for decentralized, field-level installation, the switches also reduce wiring effort.

In addition to the switches, the TX700Q was implemented as an IIoT gateway. It serves as the interface between the sensors and the higher-level system and, as a PLC, controls data transmission and processing, thereby reducing overall system complexity. The TX700Q is particularly well suited for less complex applications, as it allows for simple integration into existing infrastructures. With three RJ45 Ethernet ports and one serial interface, it provides sufficient connectivity for communication with various devices and systems. In addition, the gateway supports programming of logical functions using CODESYS, which simplifies adaptation to specific application requirements and shortens implementation time.

Combining the TBEN-L5-SE-M2 switches with the TX700Q IIoT gateway ensured reliable and efficient data transmission within the production environment. "In addition to the hardware, Turck Multiprox also provided a CODESYS software solution to enable integration with our WMS system. Thanks to TURCK's solution, our AGVs are controlled autonomously and reliably," explains van den Berghe.

Autonomous AGV control around the clock

With the new solution, Proferro is now able to reliably detect whether pallets are present and to transmit this data wirelessly to higher-level systems. This information forms the basis for autonomous AGV control and thus enables smooth, around-the-clock operation.

"Two key elements were critical to the successful implementation of this solution," summarizes Mathieu van Den Berghe. "The software, which reduces complexity and enables easy monitoring, and the reliability of the sensors. Our experience to date has shown that TURCK components deliver exceptional reliability and require no maintenance at all. This makes them an extremely cost-effective and robust solution—exactly what we were looking for."

Customer | www.proferro.be

Bart Baert is a sales manager at Turck Multiprox in Belgium