Cloud-based level measurement in silos

Adfil demonstrates that sensor- to -cloud solutions do not have to be expensive or complex, using a smart level monitoring solution from TURCK that optimizes both purchasing and production at the same time

Quick read

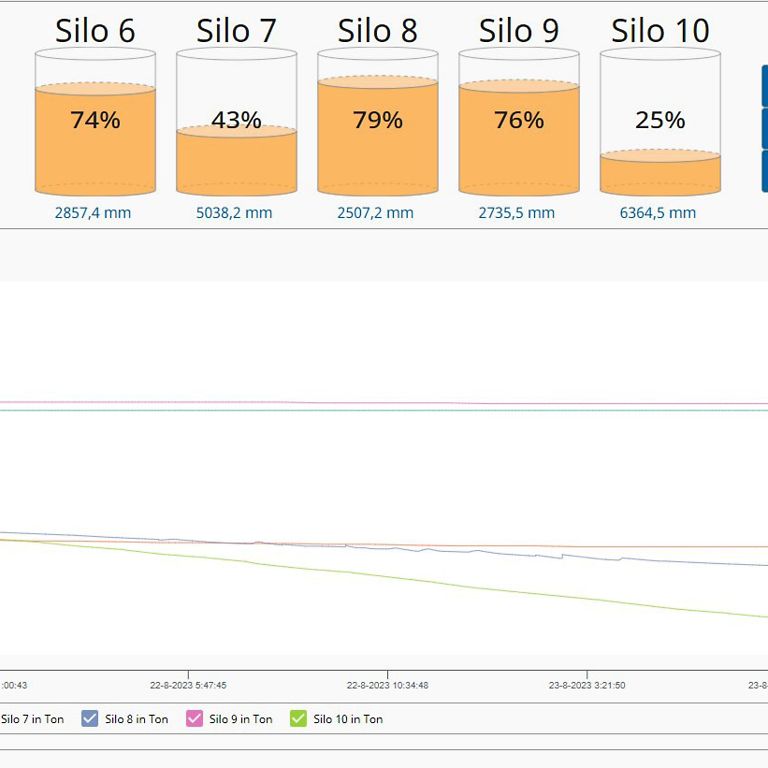

The correct supply of raw materials is critical in many manufacturing operations to ensure optimal production processes. This is also the case for Belgian synthetic fiber specialist Adfil , for which Turck Multiprox implemented a smart sensor- to -cloud solution that enables both purchasing and production to access real-time silo level data at any time. This ensures that the right quantity of raw materials is always available.

With more than three decades of experience, Adfil is a recognized specialist in the development and manufacture of synthetic fibers for concrete reinforcement. Headquartered in Zele, Belgium, the company produces the synthetic fibers in various versions for transport concrete, precast concrete and shotcrete. In its in-house engineering department, Adfil's specialists determine the exact fiber dosage for each concrete mix, which is used in a wide range of applications—from concrete floors and paving to tunnel linings and precast concrete elements for walls or fences.

Using synthetic fibers in concrete offers numerous advantages. For one, it saves time because no steel reinforcement mats are required—the fiber reinforcement is already integrated into the concrete. It also saves money, since the cost of steel reinforcement is significantly higher than that of fiber reinforcement. In addition, a considerable number of labor hours can be saved on the construction site.

"We are very satisfied with the solution from Turck Multiprox. At a very reasonable price, our employees in purchasing and production can now continuously monitor the granulate inventory in our silos and act quickly, so that supply is always tailored to our needs."

Guy De Vuyst | Maintenance Engineer | Adfil

Reduction of the environmental footprint

Choosing fiber-reinforced concrete is also a good step in terms of sustainability and reducing the CO₂ footprint. Independent reports show that using these fibers can reduce CO₂ emissions in structural reinforcement by up to 90 %. In addition to eliminating the need for steel, the significant reduction in vehicle movements—by avoiding transport of steel reinforcement mats—also has a positive impact on the CO₂ footprint.

In the past, electromechanical sensors were used to measure the level of granulate in the storage silos. However, this did not allow for continuous measurement. Operators on the production floor had to manually retrieve the level of each silo at the push of a button on a panel. The readings corresponded to a specific volume shown in a table on an A4 sheet displayed next to the panel. Although this approach worked, it was not ideal—partly because the measurements were not always accurate and the system often became mechanically jammed.

At lower utilization levels, it could therefore happen that the fill level of certain granulates was not measured frequently enough, creating the risk of a production stoppage due to a shortage of raw materials. For this reason, Guy De Vuyst , maintenance engineer at Adfil , decided to automate the level measurements. Finding accurate yet cost-effective sensors initially proved to be a challenge. Although specialized solutions were available, their prices were outside the planned budget.

Continuous level measurement using a laser sensor

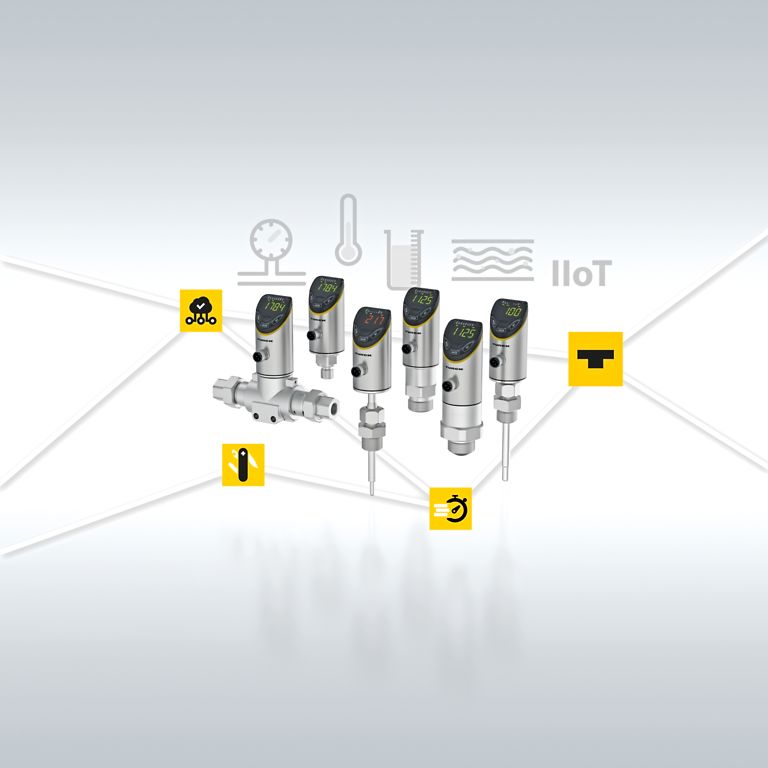

It was different with Turck Multiprox. TURCK's Belgian subsidiary was able to offer a solution that was not only a perfect fit in terms of price: the LTF12 laser sensor from TURCK's optical sensing partner Banner Engineering. This laser sensor with an IO-Link output has a range of up to 12 m and a resolution of 0.3 to 3 mm. The sensor's measurements remain accurate and reliable even over long periods of time. Because the sensor is so powerful, the lenses do not need to be kept clean with high pressure to ensure correct measurements, making the LTF12 ideal for this application.

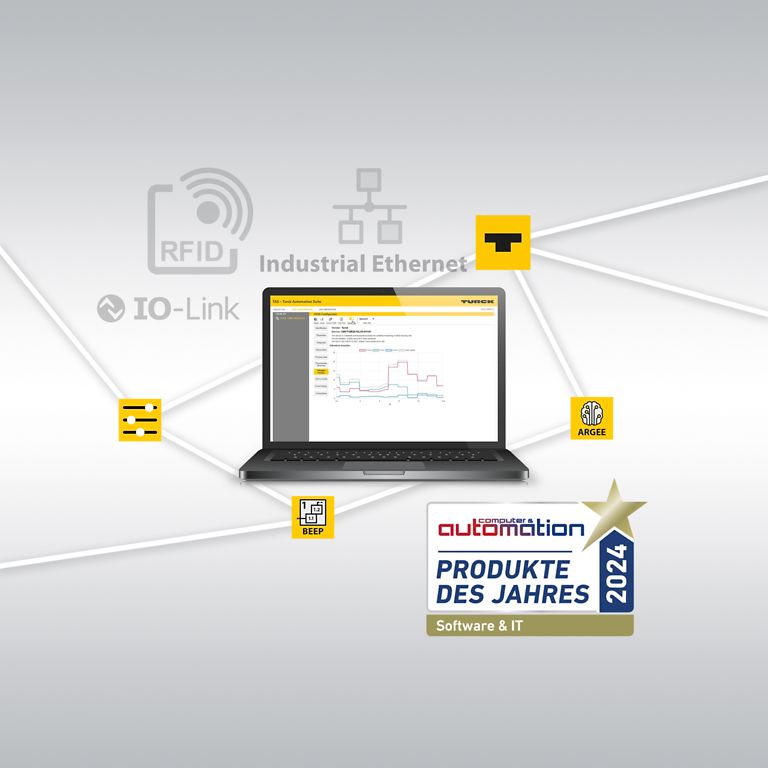

Another benefit of Turck Multiprox's involvement was the development of a flexible, end-to-end solution. They supported not only the selection of the most suitable hardware but also component configuration and the programming of certain parts of the code. The IO-Link sensors were connected to TURCK's FEN20-4IOL, one of the most compact IO-Link masters on the market. This multi-protocol I/O station with four IO-Link master channels also offers a high degree of flexibility, since it can be used as an EtherNet EtherNet/IP device, a Modbus TCP server and a CANopen server. The IO-Link masters are connected via Profinet to a Siemens PLC. From there, the data is visualized locally on HMIs in WinCC. In addition, the data is forwarded via OPC UA to the Ignition SCADA system

Sensor- to -cloud solution supports procurement service

For Adfil's purchasing department as well, it was important to be able to act quickly and correctly based on the measurement data—even when not on site. Delivering to the production facility too quickly can lead to excess inventory in one of the silos. Delivering too slowly can result in a shortage of raw materials and, in the worst case, a production stoppage. Turck Multiprox developed a cloud solution for this purpose that allows employees in both purchasing and production to monitor the correct fill level in each silo at any time.

TURCK's dual-core TX700 IoT gateway with a CODESYS V3 controller is used for this purpose; it reads the IO-Link masters in parallel via Modbus/TCP. The TX700 is a true Swiss Army knife, offering a wide range of communication, visualization and programming options. The device is future-proof and a perfect fit for modern companies' Industry 4.0 strategies.

Summary

As this example shows, digitizing a comparatively simple task can also deliver enormous efficiency gains. With this admittedly straightforward and cost-effective IIoT application, Adfil now benefits from continuous measurement data available everywhere—data that makes optimized purchasing and production processes possible in the first place. Guy De Vuyst confirms this:: "We are very satisfied with the solution from Turck Multiprox. At a very reasonable price, our employees in purchasing and production can now continuously monitor the granulate inventory in our silos and act quickly, so that supply is always tailored to our needs."

Customer | www.adfil.com

Hans De Craemer is a marketing manager | Turck Multiprox in Belgium