Radar Sensors for Precise Level and Distance Measurement

TURCK radar sensors for level and distance measurements allow factory and logistics automation to benefit from the advantages of this technology – including visualization using the TURCK radar monitor

The Fast Read

Whether it’s dip coating tanks or container ports, radar technology provides tangible advantages over alternatives such as ultrasonic or opto-electric sensors in many application areas. Despite this, radar sensors have rarely been used in production and logistics for distance or level measurements to date. TURCK now offers efficient solutions for demanding applications in these areas with its LRS+ and DR-M30 radar sensors as well. The browser-based TURCK radar monitor for the visualization of the signal curve for setting precise measuring ranges sets a new benchmark.

Most people associate radar technology with speed cameras on public roads. Over the past decade, this technology has been increasingly put to use in the car itself. Active distance control systems, known as adaptive cruise control (ACC), use radar to determine the distance to the car driving in front and its speed.

For a long time, radars were rather exotic in industrial automation. The processing industry, in contrast, has been using this technology for fill level measurement for a while now. Since radars reliably detect fill levels without any contact with media, even over long distances, in many applications they exhibit significant advantages over ultrasonic and opto-electronic technologies, or technologies requiring media contact. In production automation, the use of radars was, for many years, usually limited to safety sensors for detecting protective fields, for example on AGVs.

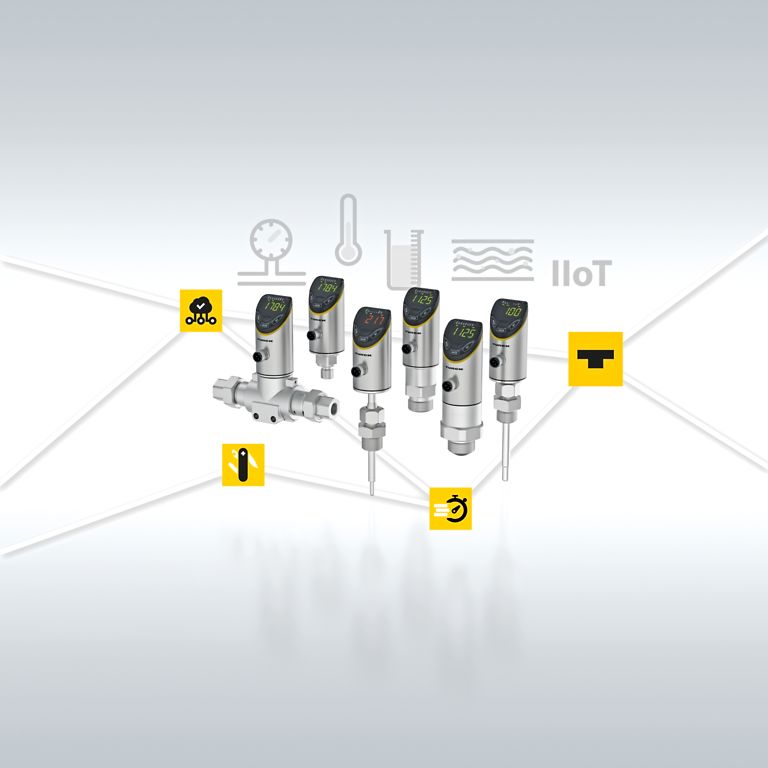

TURCK launched its first in-house radar sensor, the LRS+ fill level radar from the Fluid+ product family, in 2021. The IO-Link-capable radar sensors have been developed for level measurements within a range of 0.35 to 10 meters. The devices with protection class IP67/69K are therefore suitable for longer detection ranges and provide more detailed options for suppressing interference signals than the LUS+ ultrasonic level sensor, which is also based on the Fluid+ sensor platform.

Additional data for easier condition monitoring

One characteristic feature of the Fluid+ platform is the control unit with capacitive touch pads and a translucent front cap that the LRS+ uses to display distance, fill level and volumetric values. The lack of a metallic guide rod makes it suitable for use in hygienic areas and makes commissioning straightforward. LRS sensors are available with either two switching outputs, or with one switching output and one analog output. Their additional IO-Link interface and intelligent, distributed signal preprocessing mean all models can also provide plenty of additional information for processing in condition monitoring applications in the IIoT: Along with the signal strength, this also covers temperature values, operating hours or switching cycles.

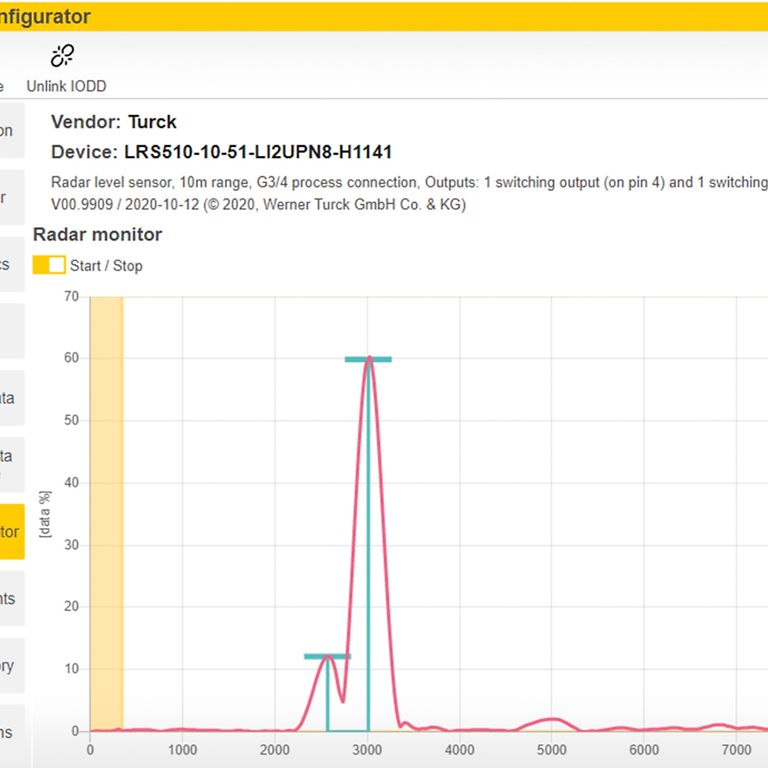

Radar monitor visualizes the signal curve

The TURCK radar monitor is a browser-based configuration tool that, among other functions, displays the radar’s signal curve and provides access to all relevant parameters in plain text. Until now, detailed analytical functions like this have been limited to high-end radar sensors used in the process industry. With its radar monitor and the visualization of the signal curve in particular, TURCK is also making it easier for its customers to configure production automation systems. A signal from a stirrer or grate that is causing interference, for example, is easy to suppress, or the sensor can be perfectly aligned using real-time feedback to maximize the reliability of fill level detection in challenging applications.

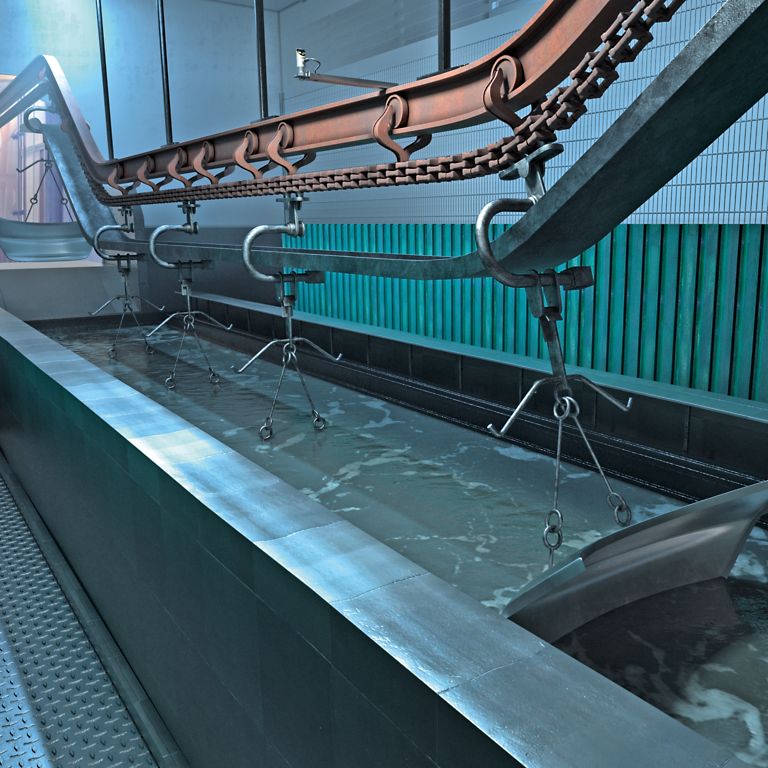

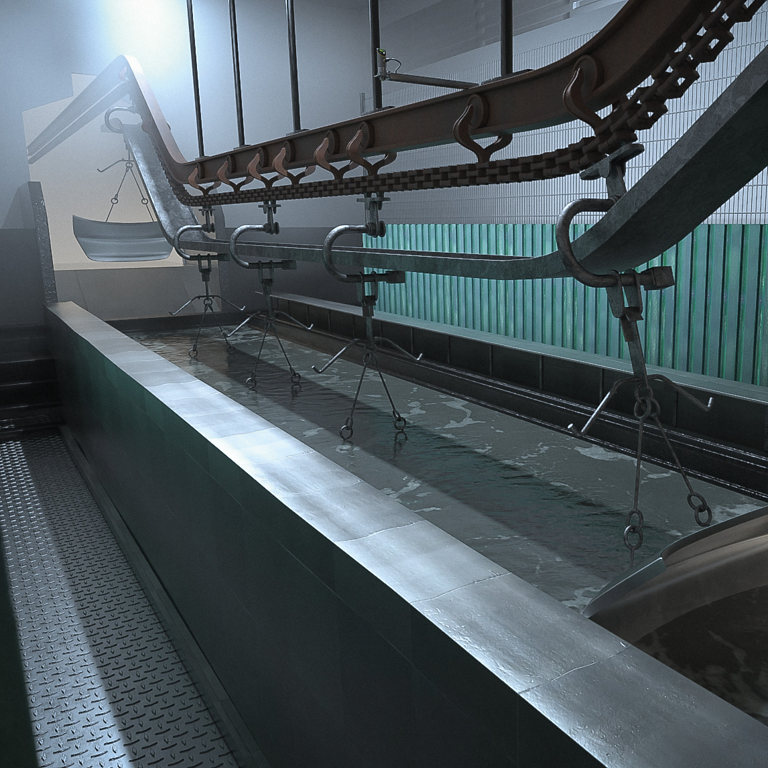

Application: level measurement in a dip coating bath

There's one application that makes the benefits of radar-based level measurement particularly evident, and it is the measurement of the fill level in dip coating tanks. In this process, body parts are coated using cathodic dip coating (CDC) – also known as cataphoresis. This involves using an electrical field to help attain a uniform and durable surface coating, even on workpieces with a complex structure.

Users need several items of information to immerse the workpiece, which is secured to a conveyor belt, fully and safely into the coating medium. On the one hand, this means ensuring that the conveyor belt is mounted at the correct height. On the other hand, it must be ensured that the fill level of the coating medium in the tank is correct. Added to this is the challenge that the high currents used in the coating process present.

Since immersion sensors only exhibit limited suitability for the cataphoretic process due to the high currents used for it, users generally employ non-contact measurements of the fill levels. Conveyor mechanisms and other structures between the level sensor and the immersion bath can, however, lead to unwanted signals and incorrect measurements of the immersion bath fill level.

The TURCK radar monitor helps the user to suppress interference pulses caused by metal supports or the car body itself. The graph with the signal curve clearly shows a large peak emitted by the main goal, the immersion bath, as well as smaller peaks, caused by the transport hooks that pull the body parts through the immersion bath, for example. These interference pulses are very easy to suppress by defining an individual measuring window.

The easiest way to access the TURCK radar monitor is by using TURCK’s IO-Link master. No additional software is required to open the radar monitor by using the IODD configurator. The TURCK IO-Link masters automatically download the IODDs of the radar sensors.

Another useful feature of the LRS+ radar level sensors is the alphanumeric 2-color display that the sensor has in common with the other products in the Fluid+ family. To improve the visibility of critical fill levels, the display can be configured so that a change of color from green to red occurs. This allows every employee in the field to see immediately, even from a distance, when critical fill levels are reached.

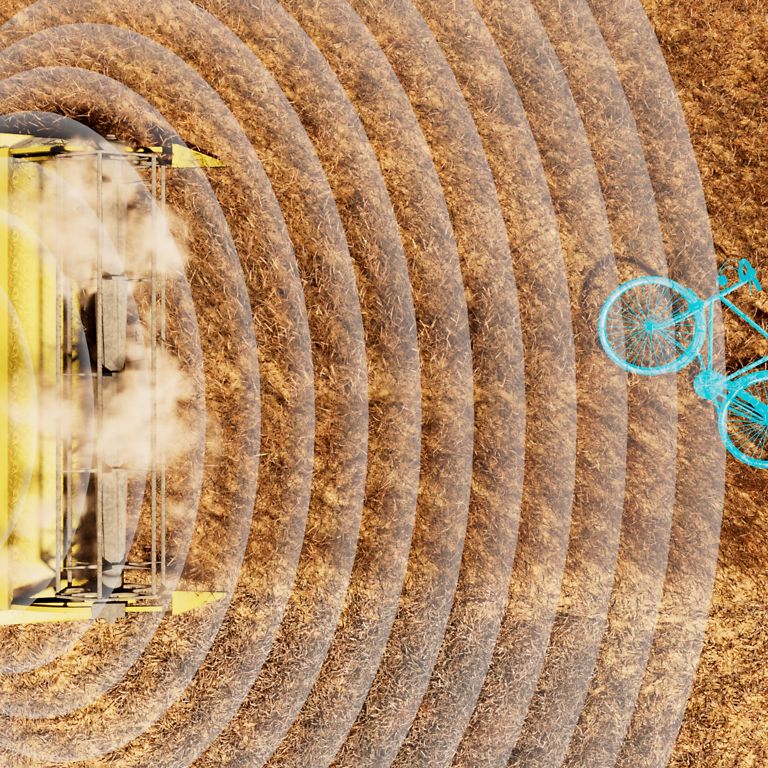

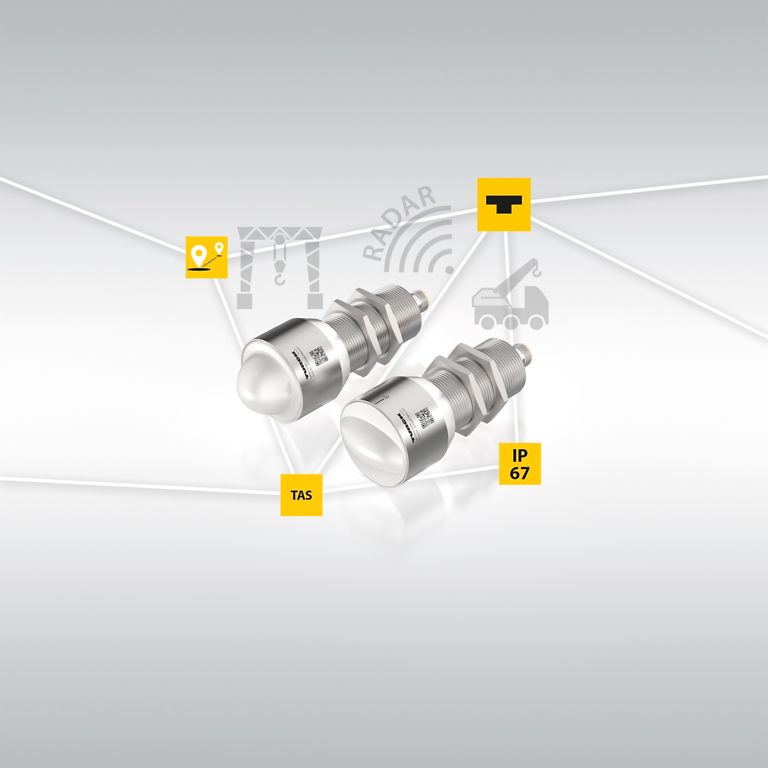

DR radar sensor for outdoor distance measurements

Once the level measurement radar sensor had been developed, it seemed obvious to adapt the technology for applications that do not require a display and an operating menu on the sensor – namely for distance measurements. Consequently, TURCK is now introducing the DR-M30-IOL distance radar sensor. With ranges from 0.35 to 15 meters, a stainless steel housing and shock resistance of up to 100 g, it is also designed for use in extreme environments. The sensor shares the same radio frequency of 122 GHz as the FMCW radar, along with the IO-Link interface and protection class IP67/IP69K with its LRS technology counterpart for level measurements.

Its properties not only allow its use in harsh factory automation applications, but also in mobile or outdoor applications. This makes the sensors ideal for distance measurement in port logistics, for example, for which opto-electronic or ultrasonic sensors are often unsuitable due to their limited range or due to interference from factors such as dust, wind, or light.

As is the case with the level measurement radar, the TURCK radar monitor also makes device configuration easy for the distance radar by using the real-time display of the signal curve – especially when setting filters to suppress signals causing interference or in tricky installation situations. Alternatively, IODD interpreters such as PACTware can be used to configure the IO-Link devices. When mounted in close proximity to each other, the FMCW measuring principle used by the devices prevents signals from affecting each other. In addition to IO-Link, all DR-M30-IOL sensors feature an analog and switching output, whereby the analog output can also be configured as a second switching output.

Application: distance measurement on container bridges in port logistics

This can be a real help in industries such as port logistics, for example. Sensors for distance measurement on container bridges are suitable for this area of use. Grippers that are used to transfer ISO containers from ships to trucks or rail wagons are held with spreaders, as they are known. The distance between the spreader and the container must be continuously detected to prevent any collisions and to control the speed. Its stainless steel housing allows the DR-M30-IOL to also withstand harsh, salty coastal air. And because things sometimes get a little rough in port logistics, the shock resistance of 100 g has real benefits in this field of application.

The spreaders aim for the container in the near field using what are known as flippers. These mechanical guide tools ensure precise docking of the container down to the last centimeters, so that the spreader reliably grips the transport lugs. However, the fully extended slippers also widen the dimensions of the container. The plant control must offset this information from the distance signal provided by the distance sensors in order to prevent collisions in tightly stacked container towers as well. The distance sensor is also ideally suited for measuring the distance between the individual container bridges.

Models with an alternative lens configurations for longer distances

Along with the DR-M30 with a standard lens that is now being showcased, TURCK will be adding models featuring alternative lens configurations to its product range in the coming months: A sensor version with a long and narrow detection field is ideal for larger distances of up to 20 meters, as are encountered in port facilities. An additional lens configuration enables a wide field with a short range, for example of the type used for object detection for collision protection.

Raphael Penning is Product Manager for Radar and Ultrasonic Sensors at TURCK