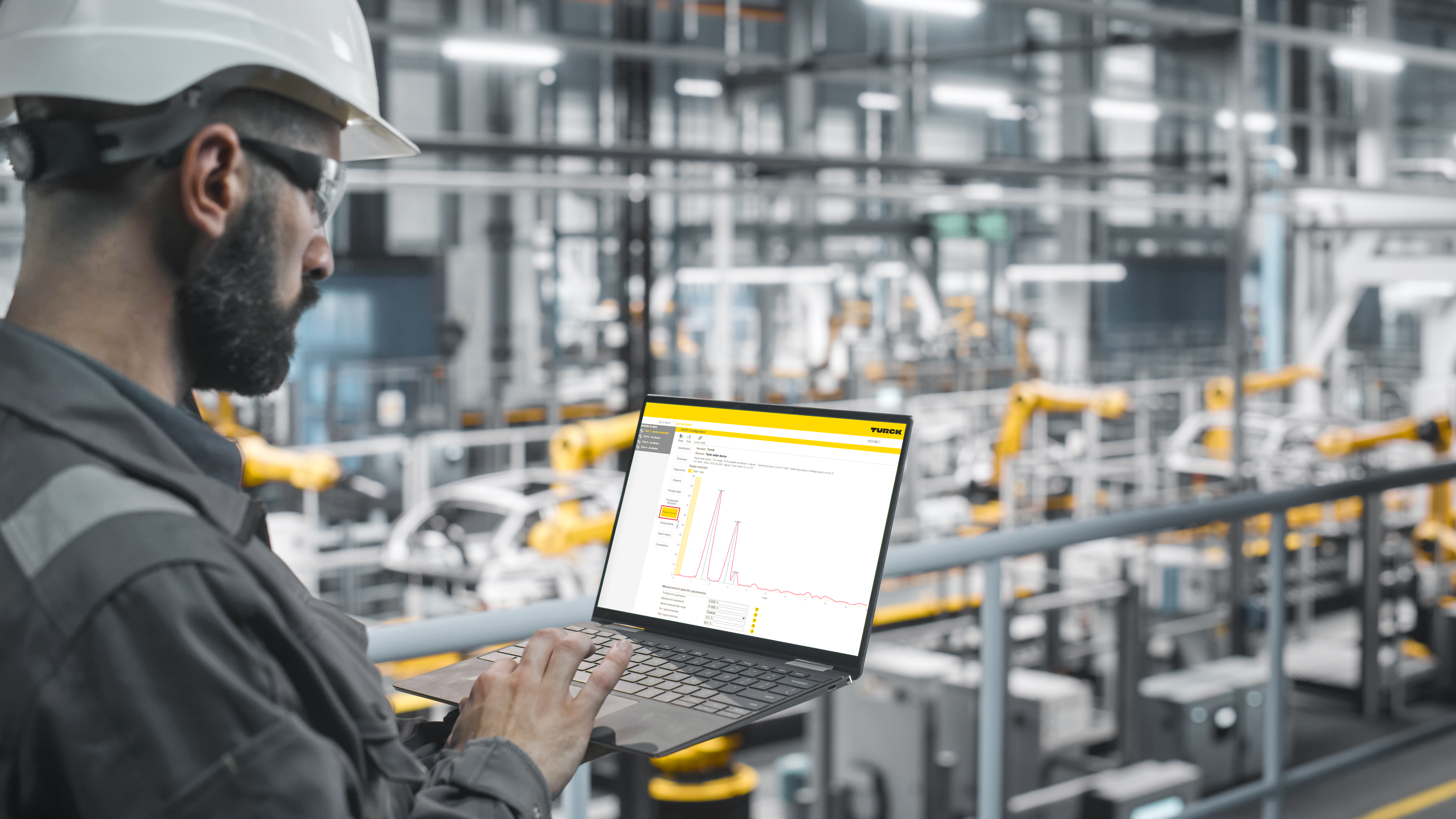

TURCK Automation Suite TAS

TAS is the IIoT ecosystem for smart automation. TAS facilitates the automation of your machine throughout its entire product life cycle – securely, scalably, and intuitively

The TURCK Automation Suite (TAS) IIoT platform connects the entire machine lifecycle – from concept to service, digitally and seamlessly

The TURCK Automation Suite (TAS) is a modular IIoT ecosystem that digitally maps all phases of the machine lifecycle – from proof of concept and commissioning to condition monitoring and remote service in the field. With four modules (Desktop, Cloud, Edge, Mobile), TAS combines configuration, networking, data analysis, and service in one suite. Batch functions, diagnostic and monitoring apps, role-based dashboards, secure remote access, and automatic device configurations ensure efficiency, transparency, and future-proofing – even in heterogeneous and brownfield environments. Machine manufacturers, maintenance technicians, production managers, and system integrators benefit from faster commissioning, fewer errors, greater transparency, and more efficient service processes.

The central idea behind the TURCK Automation Suite is as simple as it is consistent: Instead of combining stand-alone solutions for sensors, I/O, controller, network management and service, TURCK offers TAS, a suite that integrates all these functions throughout the entire machine lifecycle. TAS accompanies machine builders, system integrators, maintenance engineers and production managers from requirements testing to design and production to commissioning and ongoing operation. The four modules work seamlessly together to provide a true end-to-end data flow that eliminates media discontinuity and ensures data, configuration, and process reusability.

In engineering and commissioning, TAS Desktop is the central tool. This is where configuration, commissioning and diagnostics come together. A network scan finds all TURCK devices in the network and displays device information. Batch functions allow IP addresses, firmware, programs and configurations to be rolled out simultaneously for many devices – an enormous time saving for FAT (Factory Acceptance Test), SAT (Site Acceptance Test), retrofitting or series machines, for example.

The Diagnostic View also provides a central overview of the status of all devices, including status messages and fault diagnostics. One click is enough for a comprehensive diagnostic report. Views/apps for IO-Link are available in parallel — including IO-Link web parts for parameterizing cross-manufacturer devices and graphical process data flows for fine tuning. Specific monitor apps (e.g. Radar, Vibration, Lichtvorhang) simplify sensor setup and feasibility testing in the application using real-time curves, filters and measuring windows.

TAS Desktop also addresses engineering sticking points directly: ARGEE turns TURCK'S TBEN I/O modules into robust IP67 field logic controllers for simple logic controllers on the machine; BEEP (Backplane Ethernet Extension Protocol) reduces IP addresses and binds up to 33 TBEN modules to one IP, which relieves the controller – everything can be managed centrally. And CODESYS programs can be loaded, backed up, started or stopped in control devices/modules in the network – also as a batch process.

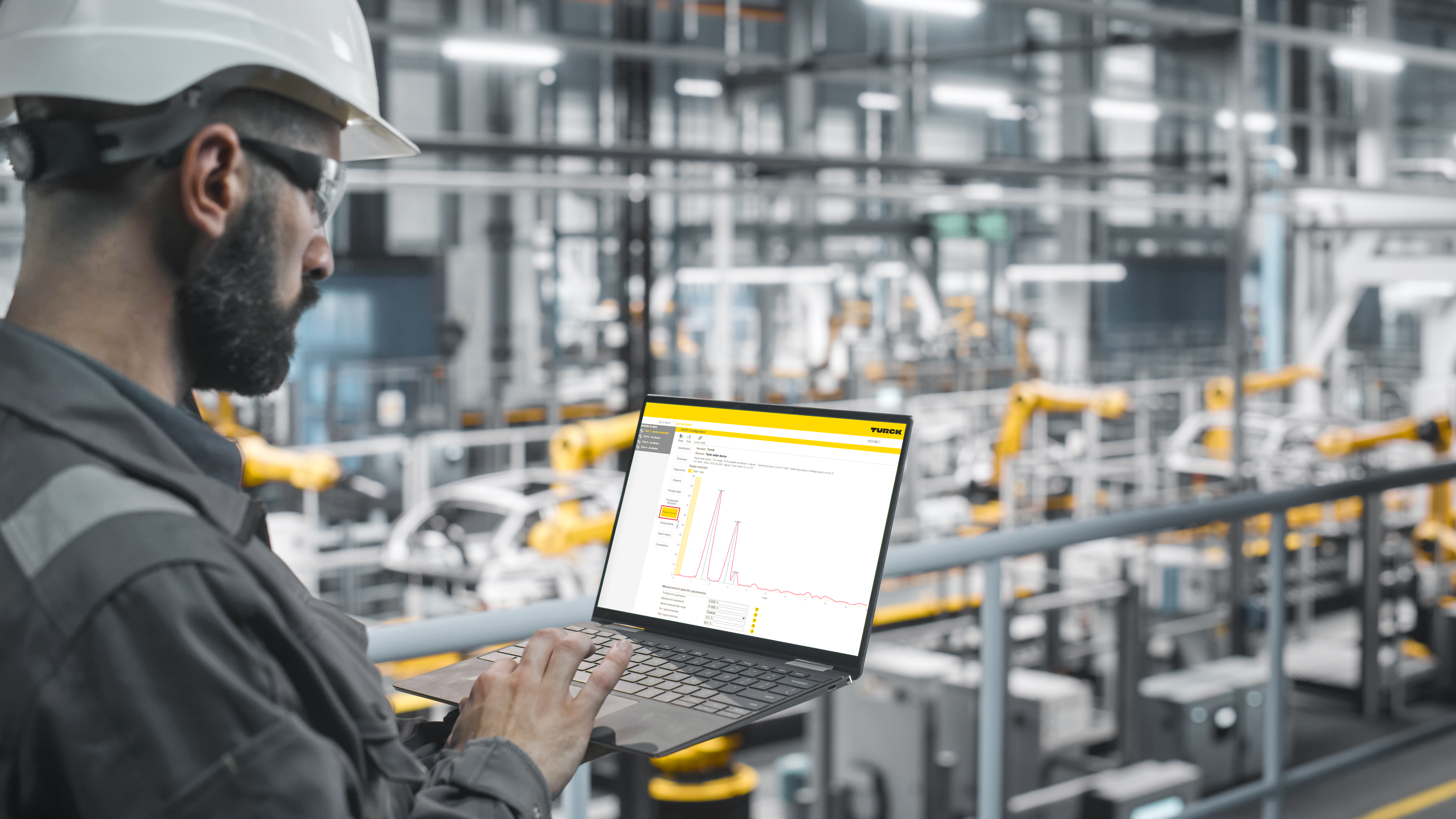

With TAS Cloud, the platform becomes an IIoT control center. Dashboards with widgets offer role-based, individually configurable interfaces for KPIs, condition monitoring, alarming, and streaming analyses – all without coding and transferable to any number of devices via templating. Continuous monitoring of the systems enables automatic reporting of critical conditions via dashboard, email, or SMS. Streaming analyses for limit values, mean values, standard deviations, and more support condition monitoring and are the gateway to the world of predictive maintenance.

Secure remote access to web interfaces, HMIs, and controllers (SSH, VNC, VPN) is provided directly from the cloud, with role-based access control. Client and role management ensure clear structures for OEMs, resellers, and end customers, while white labeling enables adaptation to corporate designs and individual domains. CSV export simplifies documentation, collaboration, and quick coordination. TAS Cloud thus brings transparency and controllability to operations – from individual machines to global fleets. Condition monitoring, predictive maintenance, and remote service become the standard, not the exception.

TAS is the IIoT ecosystem for smart automation. TAS facilitates the automation of your machine throughout its entire product life cycle – securely, scalably, and intuitively

TAS Edge is the link between OT and IT and the data supplier for machine and production data, which is used in new and existing systems for analysis, improved transparency, efficiency, and data-driven decisions. It ensures that data is collected, filtered, pre-processed, and converted into IT formats such as MQTT or OPC UA directly at the machine. This means that the data is available centrally in TAS Edge and can be forwarded directly to any IT and Cloud systems, as well as to the TAS Cloud for decentralized further processing, for example for alarming or predictive maintenance. TAS Edge also provides relevant data and future data models to enable Factory Acceptance Tests and, in the future, AI-based anomaly detection. When devices are replaced, the correct configuration is automatically imported – without manual effort or expert knowledge.

TAS Edge is platform-independent and can run on TURCK hardware as well as Windows and Linux servers, making it ideal for brownfield integration. The result is relevant, pre-processed data streams instead of uncontrolled data floods, i.e., smart data instead of big data. Production managers get KPI dashboards, integrators get simple data paths, maintenance personnel get early warnings, and IT gets clean interfaces in standardized protocols.

TAS Mobile turns your smartphone or tablet into a display replacement and service tool. Where devices do not have their own HMI or there is no view of the control cabinet or HMI, TAS Mobile enables parameterization, diagnosis, and quick help directly on site – without additional hardware. This reduces response times in the event of a malfunction and facilitates service calls in the field.

The four TAS modules form an integrated digital lifecycle in which each phase seamlessly follows the next. In the proof of concept, sensors and modules can be configured directly at the desk, initial data can be collected and clearly visualized using Edge and Cloud. During design, the focus is on the pre-configuration of controllers and IO-Link devices as well as the definition of device classes and naming schemes. In production, batch configuration makes it easier to set up sensors and I/O modules. If necessary, CODESYS and ARGEE programs are loaded centrally and test runs can be conveniently documented via Desktop or Cloud. During commissioning, users benefit from the automated assignment of IP addresses and programs as a batch process using Edge data for Factory Acceptance Tests and anomaly detection and using Mobile as a flexible tool directly on the line. During operation, TAS ensures an integrated data and process flow: Condition monitoring, predictive analytics, remote service with role management and VPN as well as the automatic device configuration during replacement reduce the engineering effort, shorten ramp-up times and make service processes more efficient and transparent.

Whether machine manufacturers, maintenance engineers, production managers or system integrators – many practical scenarios demonstrate the benefits of the TURCK Automation Suite. TAS offers the right tools for each role and phase. Machine manufacturers benefit from integrated engineering, worldwide delivery, secure remote service, one-click VPN and client structure for OEMs and resellers. Maintenance personnel can quickly access devices via Mobile, configure and diagnose devices even if they do not have a display, and receive quick help in the event of faults. Production managers use KPI dashboards, data-based process optimization, streaming analytics and direct control from the dashboard. System integrators benefit from batch processes for IP addresses and control programs, centralized management, and a scalable structure for large plants.

TAS creates an integrated IIoT ecosystem that reduces the complexity of automation, shortens ramp-up times and professionalizes service processes. The interaction of the modules is decisive: From fast setup and smart data to the visible effect in Cloud and Mobile. The suite grows with the requirements, remains open to new functions and reduces complexity in everyday life. Regular updates expand functions and apps, the modular architecture enables lean entry and subsequent scaling up to global deployment. Brownfield integration and optimized data delivery to IT systems reduce integration risks, while role-based access control and flexible organizational structures ensure secure data management. If you build, operate or further develop machines today, TAS provides you with a platform that connects engineering and operation into a digital circuit – from the sensor to the cloud, from the first idea to the last service deployment.

Christoph Rose is Product Manager for Cloud and Software

Christoph Schmermund is Product Manager for RFID Systems and TURCK Automation Suite