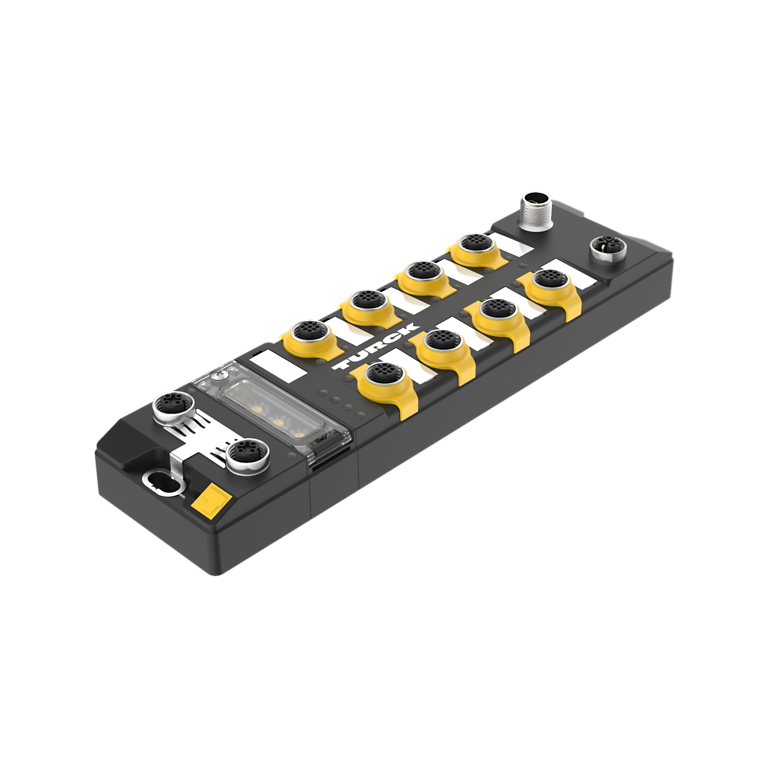

Processing safety signals from a press

The TBPN IP67 I/O module processes safe, standard and IO-Link signals directly on the manipulator's vacuum gripper

Benefits

Faster and safer commissioning thanks to stand- alone testing of the tool and simple wiring

Reduced programming effort thanks to simple IO-Link integration of devices in Profinet

Cost reduction through the use of just one I/O component

Increased flexibility, as the tool can also operate independently

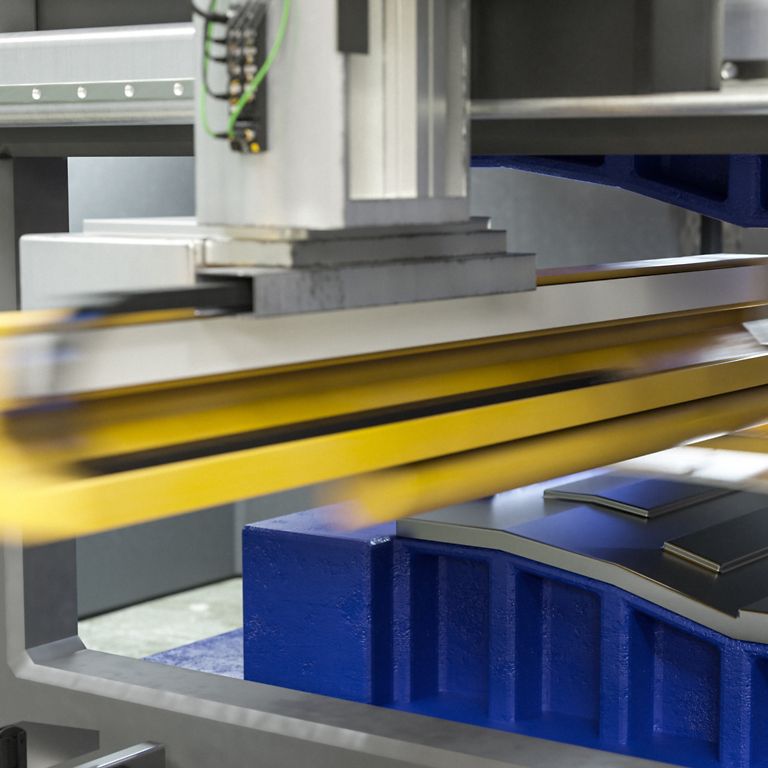

Challenge

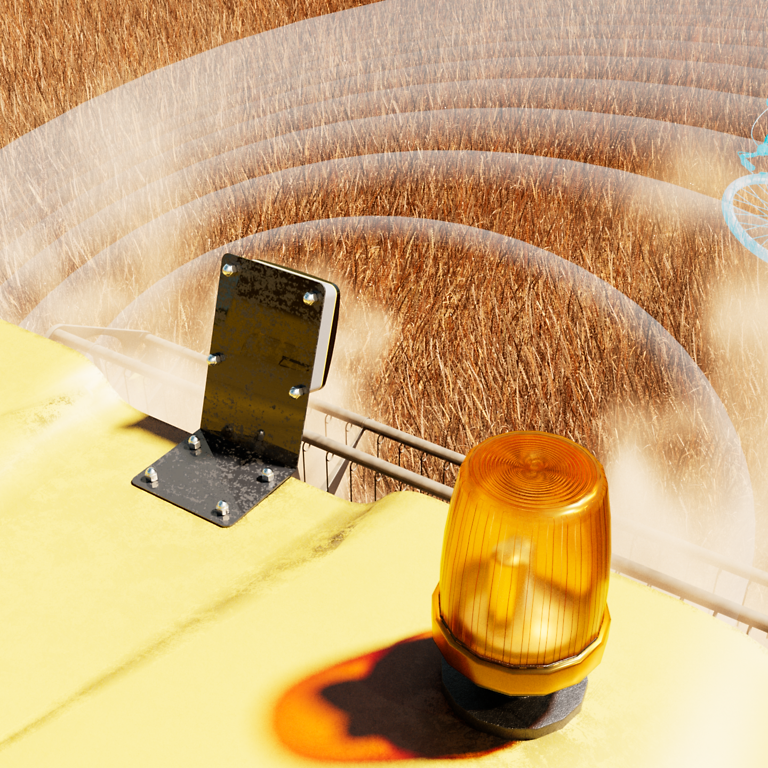

In car body manufacturing, manipulators with vacuum pickers must handle sheet metal parts safely to prevent accidents and production errors. The pressure of the vacuum pickers must be reliably monitored to ensure a secure hold. At the same time, end position and drive monitoring are required to safely shut down the handling system in the event of of danger. Until now, this required multiple I/O components, complex wiring and a separate safety controller.

Solution

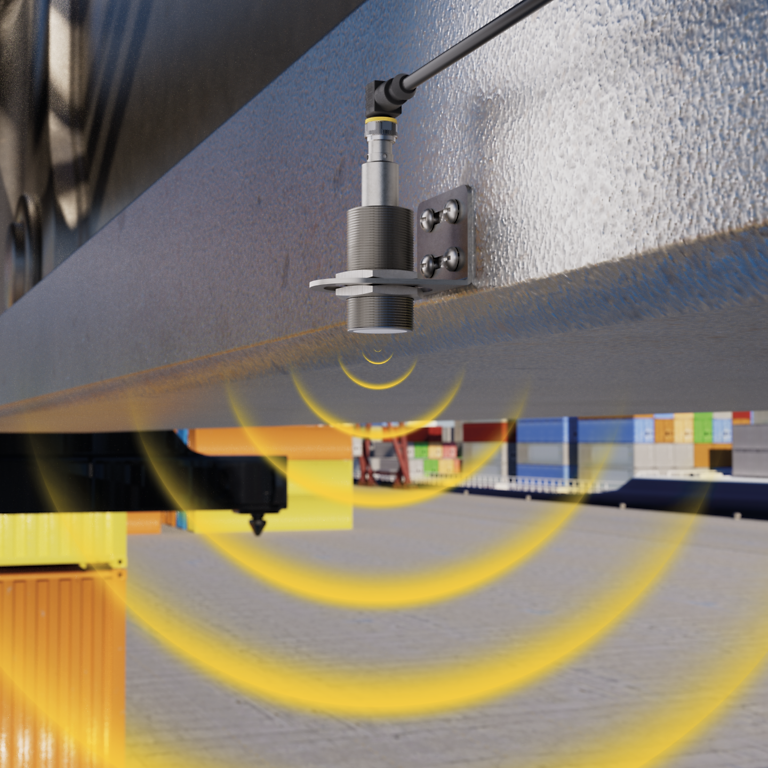

The TBPN hybrid IP67 I/O module offers Safety, Standard I/O and IO-Link ports. Two safe inputs monitor the emergency stop and pressure sensor of the vacuum pickers and forward the data to the Safety PLC. Standard I/Os detect the end positions of the sheet metal parts, while a pressure switch is integrated via IO-Link. In the event of a fault, the manipulator is safely stopped via the module's Safety outputs. One output initiates the braking process, while the second switches off the manipulator using Safe Torque Off (STO).

Thanks to the integrated Safety Controller, the system can also be tested without a higher-level Safety PLC, which speeds up commissioning. During operation, the central Safety PLC controls all safety functions. Simple IO-Link Device Integration (SIDI) also facilitates the integration of IO-Link sensors.

With IP67 protection, the TBPN is suitable for direct use on machines and significantly reduces wiring costs thanks to its decentralized architecture. This creates a compact, safe and efficient solution for presses in automotive manufacturing.

„Mit dem TBPN bringen wir Sicherheitstechnik direkt an den Manipulator – für eine kompakte und kosteneffiziente Lösung.“

Michael Flesch | Product Manager Safety Systems | TURCK GmbH