RFID solution for data acquisition in stator production

Chinese electric motor manufacturer ensures quality and traceability in stator production by tracking workpiece carriers using TURCK’s RFID system

Quick read

A Chinese system integrator is using RFID technology to automate quality assurance and traceability in a customer’s motor stator production. The customer selected TURCK’s BL ident RFID system, which integrates seamlessly into existing equipment thanks to multi-protocol Ethernet. The solution enables flexible production on complex mixed-model lines, provides real-time data for production management and supports comprehensive production monitoring. TURCK’s robust RFID technology also ensures reliable read operations even in harsh conditions, increasing the productivity and efficiency of the production line.

With the rapid rise of electric vehicles in recent years, the automotive industry has undergone significant change. Electric vehicles are increasingly replacing vehicles powered solely by internal combustion engines and promise a more environmentally friendly, quieter and lower-maintenance driving experience. A key component of these vehicles is the electric motor, which consists of a stator and a rotor. Stator assembly requires the highest level of precision, particularly during winding and when connecting the cables. The materials and components used must be recorded throughout the entire production process and be traceable at all times. This enables verification that the correct materials are being used during production.

A Chinese automotive manufacturer therefore commissioned its system integrator to record this data for its motor stator production, to ensure motor quality during manufacturing and to document the use of correct materials over the long term. An automated identification solution was required that would guarantee seamless monitoring and documentation of all production steps.

The ideal solution: digital workpiece carriers

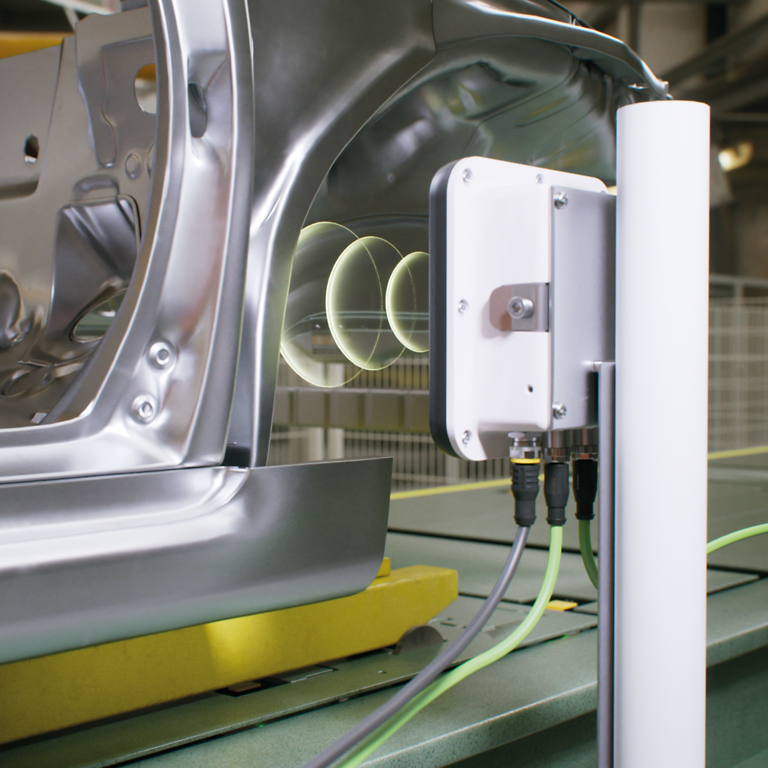

After carefully evaluating various technologies and comparing them with optical barcode identification, the system integrator ultimately chose an RFID solution to record data across the entire production process. To achieve this, the workpiece carriers are equipped with RFID tags so they can be recorded digitally.

Digitized workpiece carriers with embedded RFID tags proved to be the ideal solution. They enable unambiguous identification of the material on the carrier plate because they can be read and written contactlessly and reliably – even in demanding environments. RFID tags can also store larger amounts of data and are more resistant to contamination than barcodes.

This ensures flexible production on complex mixed-model lines, since information on each material and each stator is stored directly on the RFID tag of the respective workpiece carrier. This production data simplifies the control logic of the information management system by enabling continuous, accurate monitoring and adjustment of the production process.

Improved traceability and productivity

At the beginning of the assembly line, the relevant data is written to the pallet’s RFID tag. For this purpose, the Q80 HF read/write head with extended read range is used. As soon as a stator is placed on the pallet, the system writes a wide range of information – including the product ID – from the Enterprise Management System (EMS) to the RFID tag. Because this is a closed-loop application in which the workpiece carriers are reused within the system, no long-term storage of RFID data is required.

For efficient and reliable data acquisition, the system integrator selected a TBEN-S-RFID interface, which – as a TURCK multi-protocol device – also supports PROFINET and provides a 16 kB data buffer per channel for fast read operations. PROFINET capability enables seamless integration and high-speed data transmission within the production environment. The module offers a mode in which it automatically reports data to the control system as soon as a tag enters the detection range of the read/write head. This automatic data reporting function simplifies PLC programming and reduces the load on both the control system and the network during operation.

The Q80 HF read/write head with extended read range used in the system ensures reliable operation of the RFID system, even if a tag is not positioned exactly in the center of the read zone. For the tag, the system integrator selected the TW-R30-K2 FRAM chip, which supports up to 10 billion write cycles. Its 2 kB of memory capacity is sufficient for the process.

By implementing TURCK’s RFID system, the system integrator was able to ensure reliable traceability of materials throughout stator assembly. The production data recorded also provides a solid basis for identifying bottlenecks and sources of defects, enabling continuous improvement of production processes. With its robust IP67-rated RFID technology, TURCK ensures that the carriers can be read reliably even in harsh environmental conditions – boosting overall production line productivity and leading to a significant increase in operational efficiency.

Autor | Lin Qiang | Marketing & Product Management Department | Turck (Tianjin) Sensors Co.