This is how you automate your battery cell production

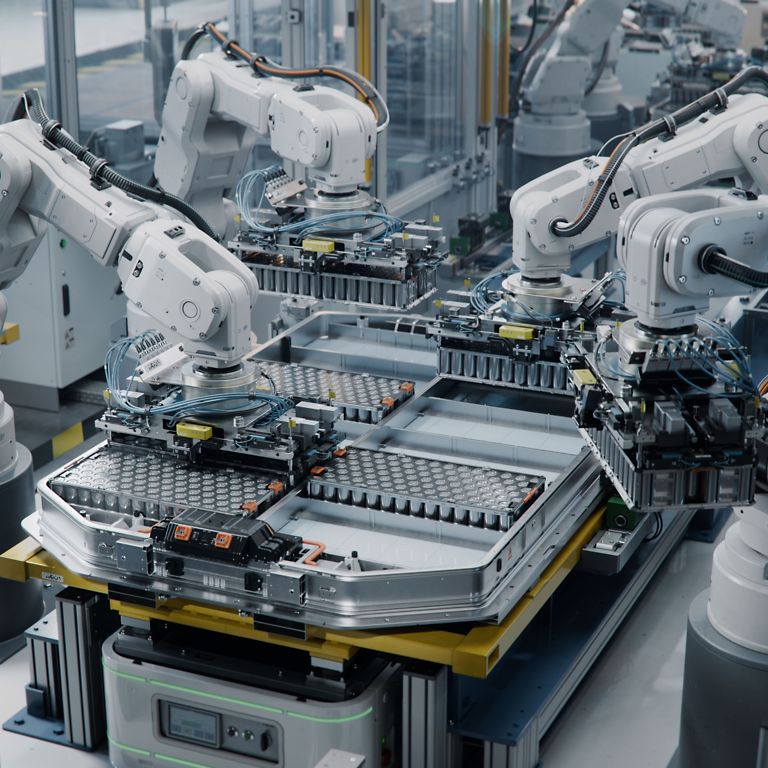

The most successful battery manufacturers rely on TURCK technology. Benefit from the data of your automation system for optimum production efficiency and highest availability with impeccable product quality.

Battery production is rapidly gaining momentum around the world. The energy and mobility transition are the drivers of this development. One thing is certain: the next 20 years of battery production will differ dramatically from the last 20 years.

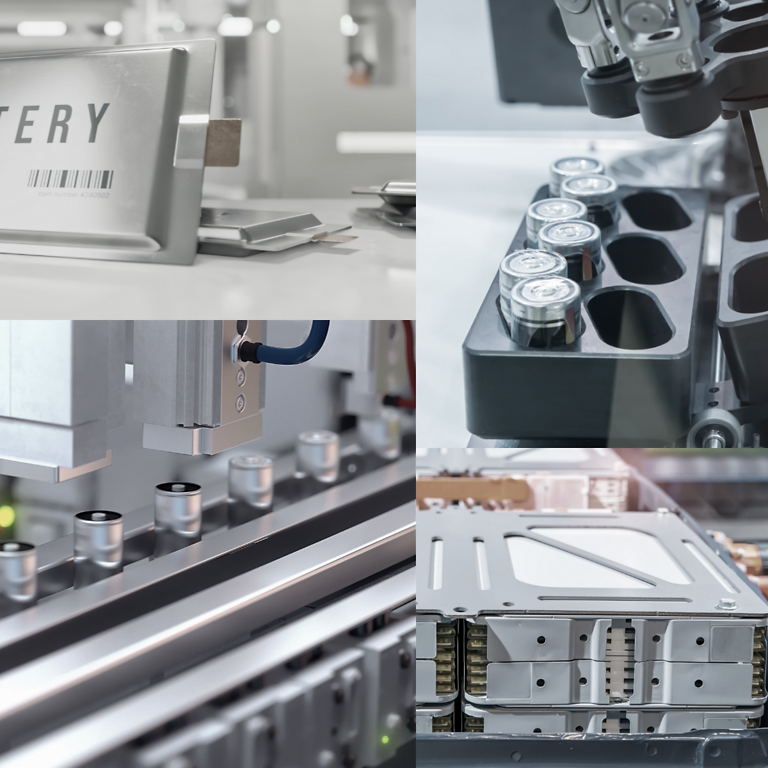

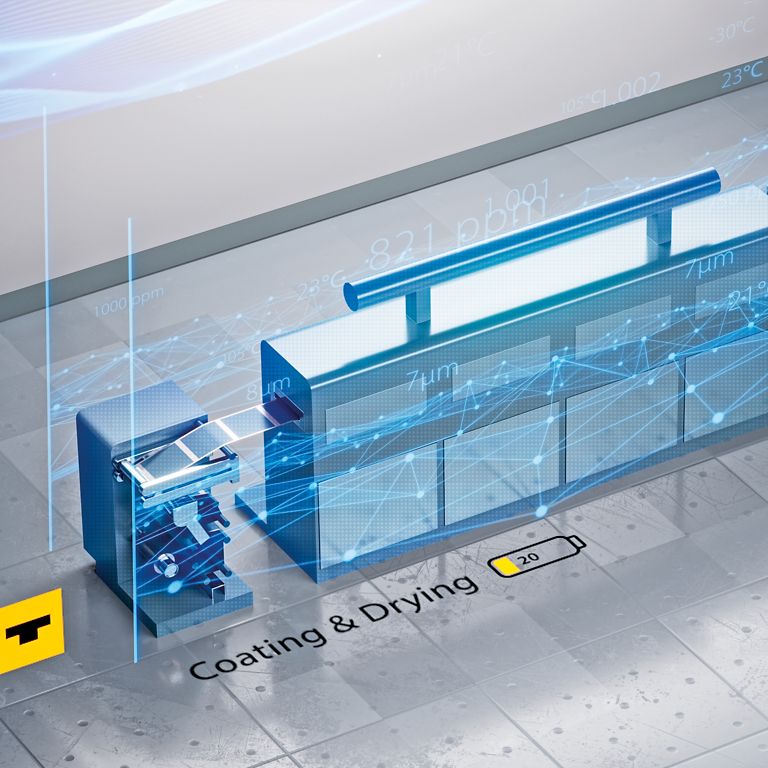

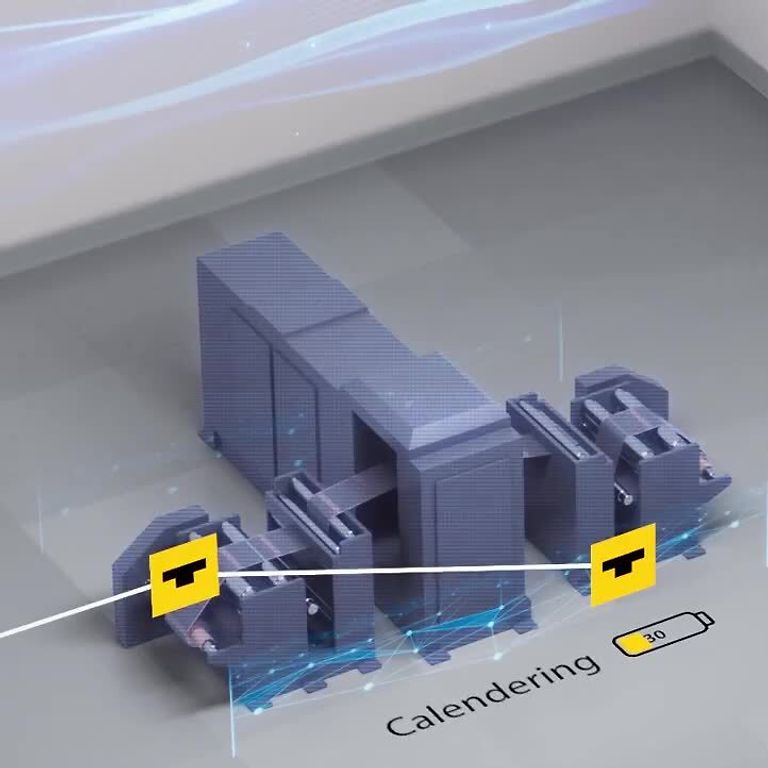

The processes and technologies for the production of battery cells will continue to develop in the coming years. New raw materials, changed mixing and coating processes or new processes for calendering and winding, there will be changes. But how can battery cell manufacturers prepare existing and future production plants for this dynamic phase and dramatically shortened innovation cycles?

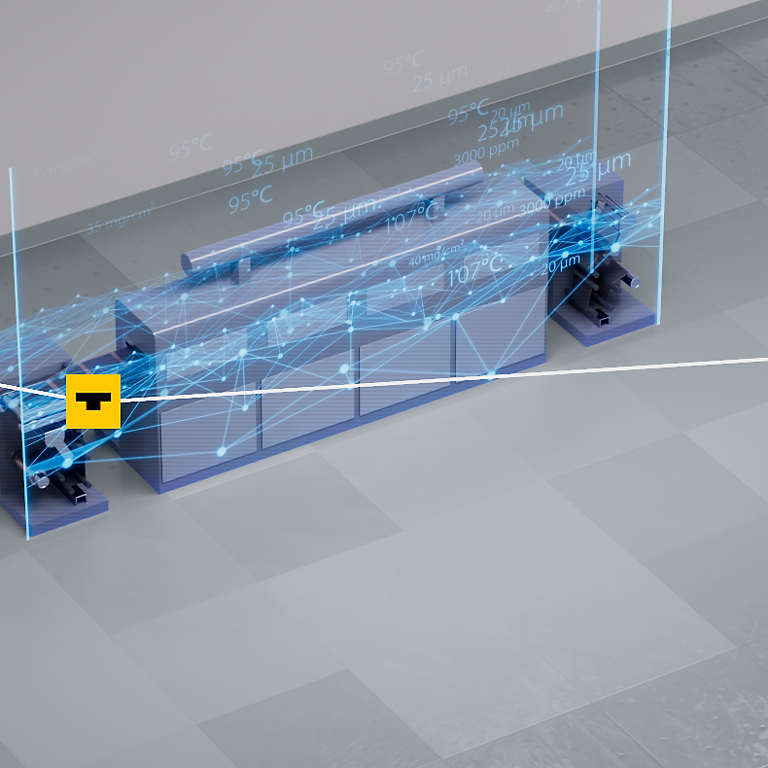

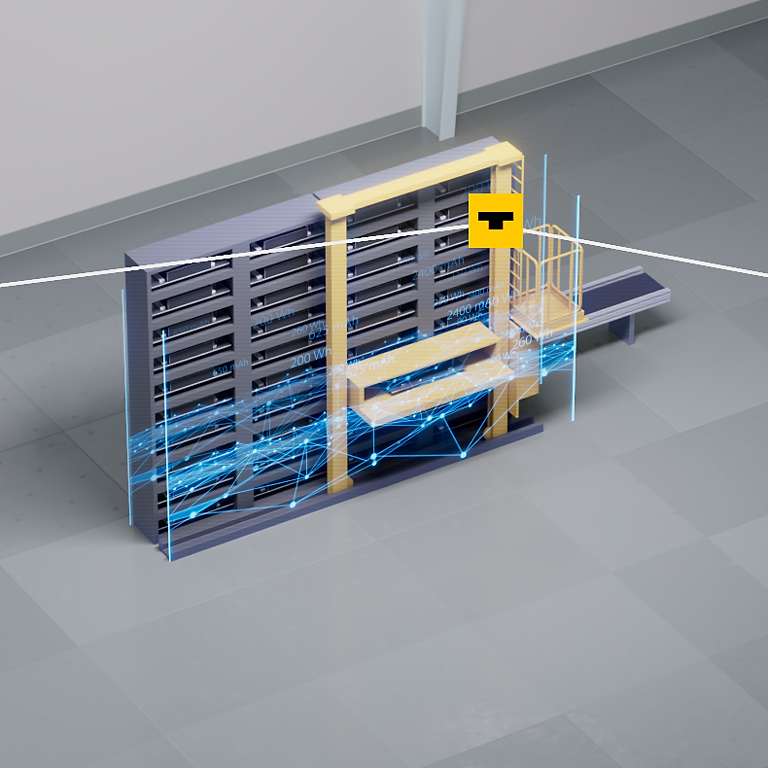

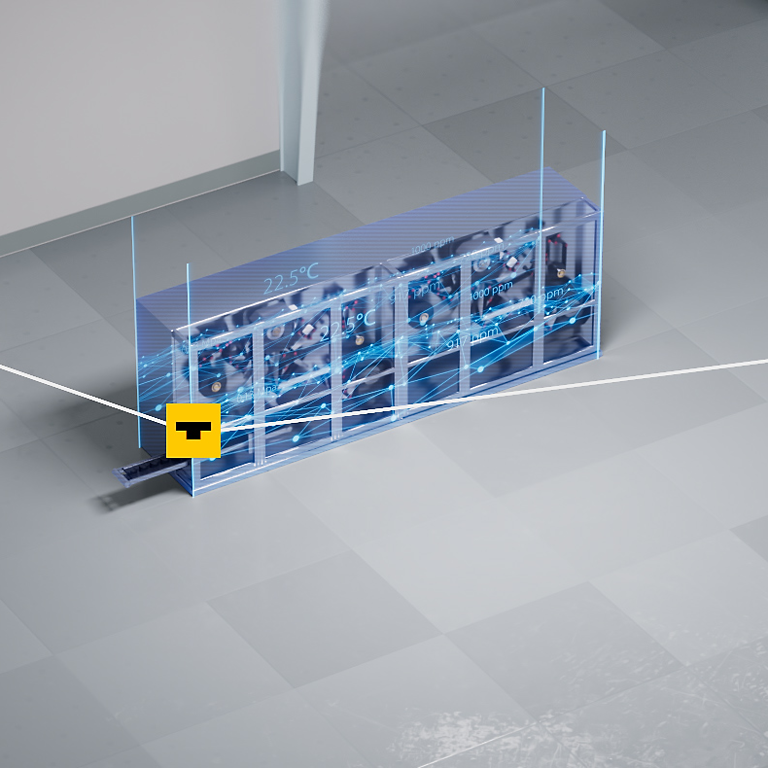

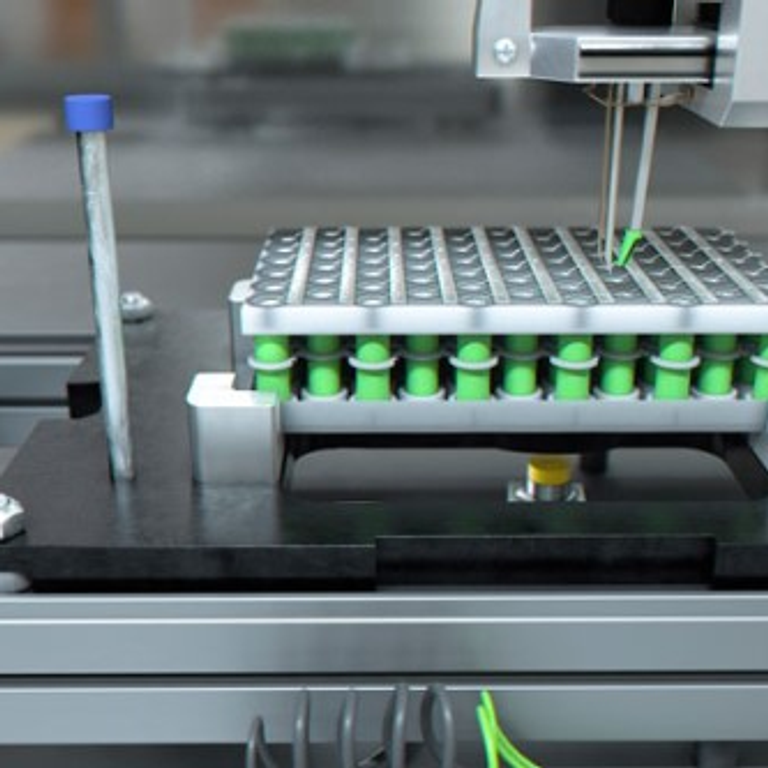

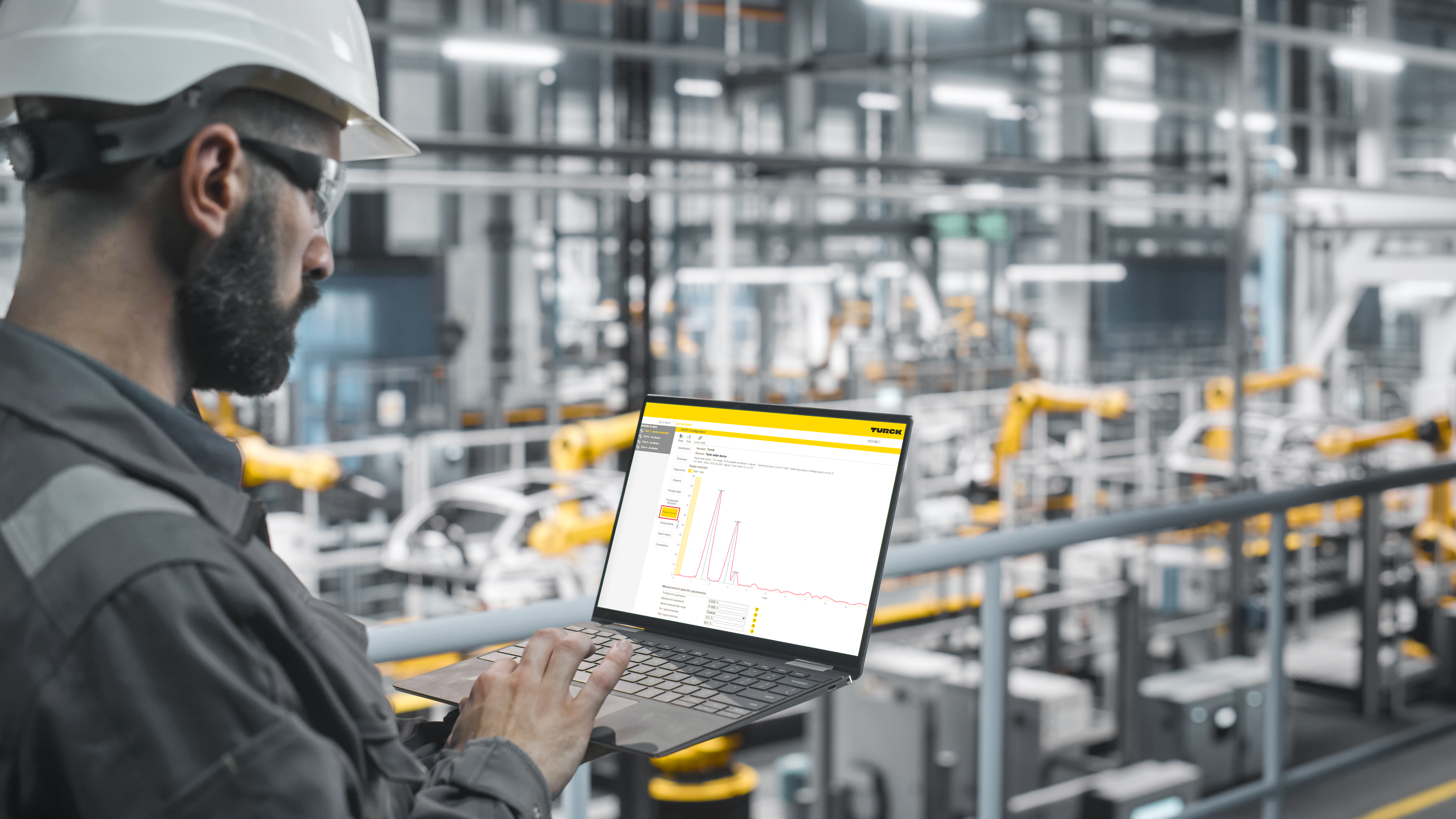

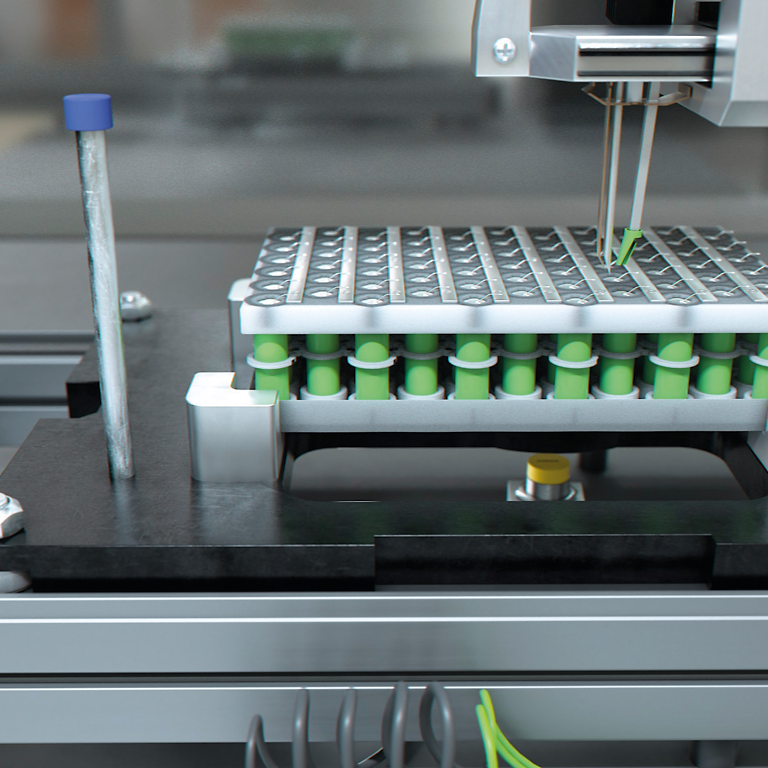

TURCK's response: with smart automation technology, data-driven process optimization, and flexible production facilities. RFID identification technology helps increase the output of existing systems while improving process reliability and product quality. Smart automation with condition monitoring detects problems at an early stage, enabling predictive maintenance that permanently increases availability and, in turn, overall equipment efficiency (OEE). Decentralized automation technology with robust, non-cabinet-bound IP67 systems makes it easier to set up modular production systems where machines can later be regrouped or capacities relocated.