Decentralized I/O modules for mobile fuel cell test rig

Turck's TBEN block I/O modules with their own LabVIEW driver improve the flexibility and mobility of the systems in test benches for fuel cells from FutureE

Quick read

Hydrogen could become one of the key enablers of a CO2-free energy supply. Companies such as FutureE in Nürtingen are constantly working on optimizing fuel cell technology to ensure this is a success. Turck's decentralized IP67 block I/O modules TBEN-S are used on a fuel cell test rig. The integrated LabVIEW driver of the modules allows direct signal connection in the test room. This speeds up the setup of the test rig and makes it considerably easier to extend the test rig and use it on the move.

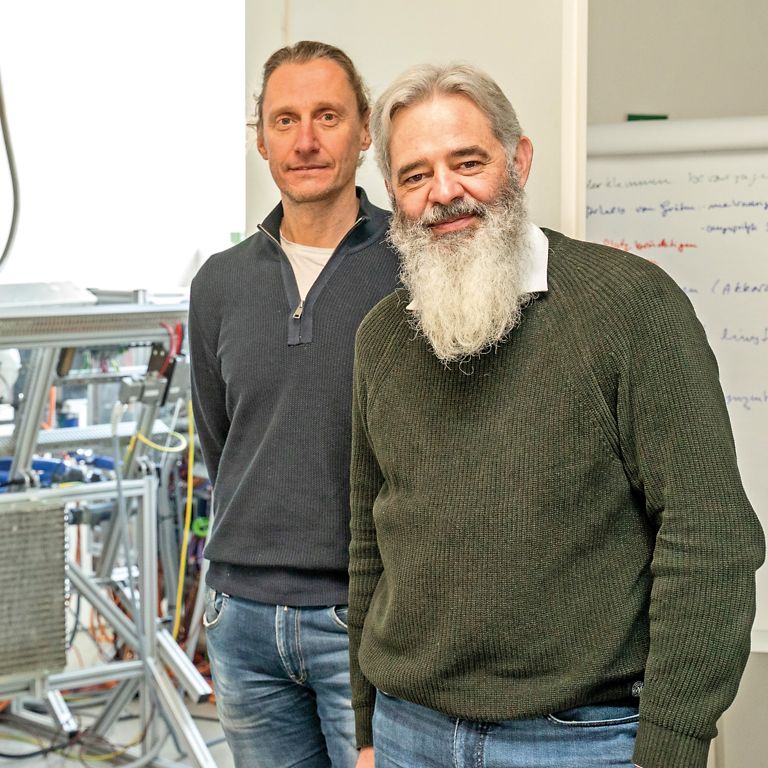

"The battery alone will not do it," says Siegfried Limmer with a view to the energy revolution. "We will need both hydrogen and battery technologies in the future." He is already experiencing on a daily basis that the demand for fuel cells is also growing as a result of this development. As managing director of the development service provider FutureE in Nürtingen, Limmer is working with its employees and partners on fuel cell systems. Its customers come from the material handling industry, the automotive and commercial vehicle industry, but also from the energy or building sector.

Potential for optimization: fuel cell system

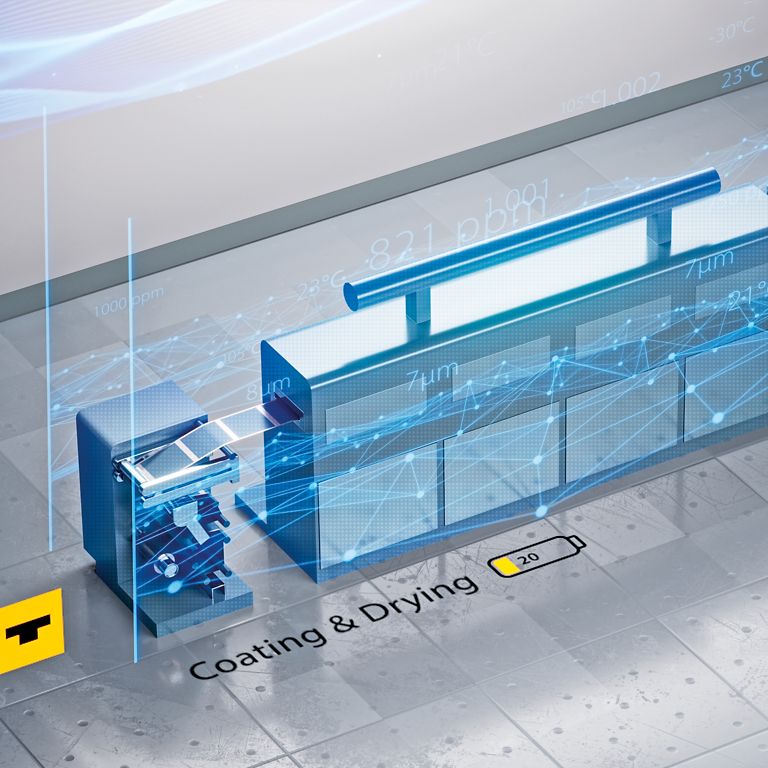

"The topic of fuel cells will grow and I assume that we will grow along with it," says the Managing Director confidently. There is every reason for this, because the use of hydrogen in a fuel cell still offers optimization potential. In this electrochemical process, hydrogen gas oxidizes at the anode, while water is formed at the cathode under oxygen supply. The electrons released in this way can drive electrical consumers. However, similar to the combustion engine, which has been continuously improved since its invention, fuel cell technology still has a lot of potential for optimization. In addition to temperatures, pressure and other conditions of the reactants, the materials involved in the reactions, such as the electrolyte or catalyst, can also be optimized.

Technical test bench

In order to be able to test its own fuel cell systems, FutureE developed a test bench, as it could also be used in a laboratory environment. And testing in this case means more than just a quality check at the end of production. Testing is the main part of the development work, because how well a fuel cell works depends on a number of parameters that are played through in countless iterations in order to determine the ideal operating parameters for different load scenarios of a fuel cell system. This ensures that the system is always operated with the ideal operating parameters under different ambient conditions – both at zero degrees and five percent humidity as well as at tropical 40 degrees and 80 percent relative humidity.

"The TBEN-S are ideal for climate tests in particular. We install them directly in the climate chamber and only have to draw a single line. And in the climate chamber, we can then add more modules flexibly – without having to pull out new lines. This flexibility is a great advantage for us.

Siegfried Limmer | FutureE

LabVIEW: quasi-standard for test benches

National Instruments' LabVIEW software is virtually the standard when it comes to extensive testing procedures in research. However, LabVIEW is also used for the operation of test benches in product development and increasingly in parallel with production. "Especially when calculating with array functions, the programming effort for a PLC is much higher. Even in the design of the graphical user interface, LabVIEW offers significantly more possibilities than a PLC, explains Albert Wais. He has known Siegfried Limmer for years, including from their time working together at a fuel cell manufacturer. Wais specializes in LabVIEW programming and supports FutureE in ongoing projects. For Wais, LabVIEW was essentially the software used to operate the test rig. The program can be used to automate entire test series and carry them out independently.

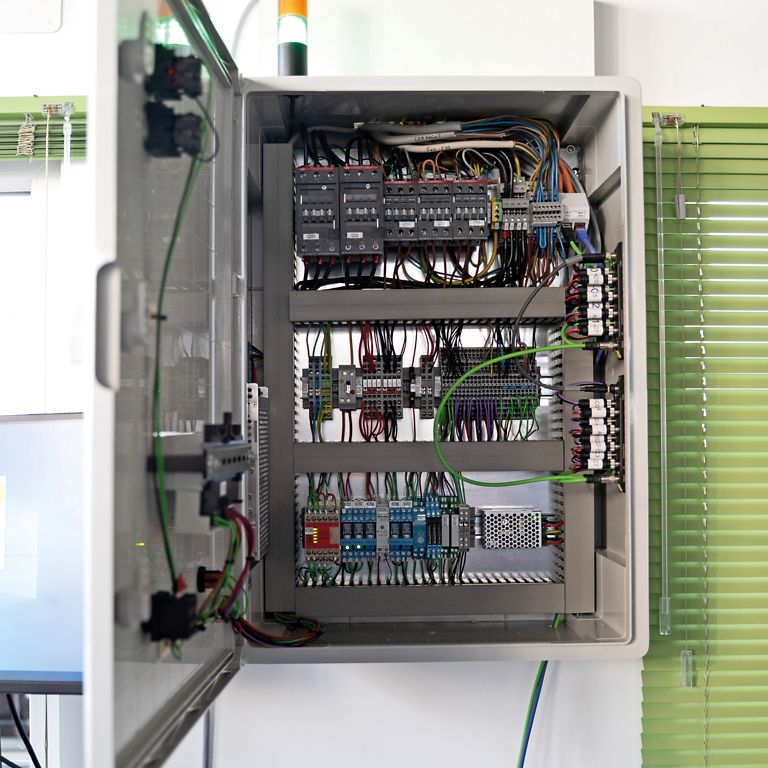

Signal connection in the control cabinet: unpopular as established

In research, benches are usually set up with a control cabinet, which houses measurement and regulation technology as well as control, IT and communication technology. The control cabinet is usually located outside the test room, as challenging climatic conditions are simulated inside. The cables to the sensors and actuators on the test bench and on the test object must therefore be routed individually from the test room to the control cabinet.

Questions often arise during the tests that could not yet be foreseen during the planning phase. "This requires additional signals. You always plan reserve channels, but in the end it's too little," says Wais, describing the dilemma from his experience. "Then a number of cables from the control cabinet must be laid in the test and laboratory area, which requires a great deal of mechanical effort and may involve new approval procedures."

Decentralized signal connection

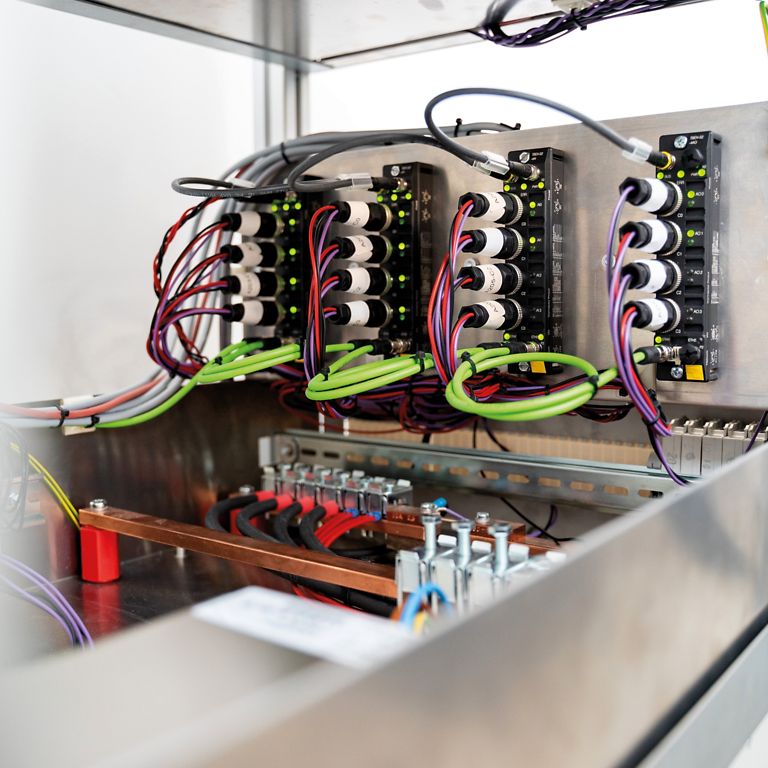

In the meantime, decentralized signal connection has become established in industry as an alternative to point-to-point connection. I/O modules with IP67 protection class are mounted directly on the machine, receive signals and transfer them to the control panel via a single Ethernet cable. To date, IP67 I/O solutions have been rarely used for communication with test benches, partly because the I/O modules designed for Industrial Ethernet can hardly communicate with LabVIEW. Albert Wais explains the situation by saying, "There is an NI driver for Ethernet/IP, but it is so rudimentary that you can't really work with it." It is understandable that National Instruments does not regard Ethernet/IP as a priority for LabVIEW, especially since the software has only been used for tests during production for several years.

Unique: IP67 I/O modules with LabVIEW driver

Albert Wais himself helped close this gap. For a project with special machine builder Kirschenhofer and Britax Römer, Wais and Kirschenhofer employees have developed a LabVIEW driver for TURCK's TBEN-S decentralized I/O modules. "This involved a herculean effort because right at the start of this project we had selected the most complex module in the TBEN-S family with the RFID module." But the work has paid off: users can now find LabVIEW drivers for most of TURCK's IP67 I/O modules in the NI driver database.

Consequently, Wais also recommended using TURCK's TBEN-S modules for signal connection with LabVIEW for the FutureE test bench. "The TBEN-S are ideal for climate tests in particular. We install them directly in the climate chamber and only have to draw a single line. And in the climate chamber, we can then add more modules flexibly – without having to pull out new lines. This flexibility is a great advantage for us," confirms Siegfried Limmer.

End customer benefits from flexibility

In addition to the signals for the sensors, actuators must also be connected to the test bench, for example for cooling water control and the cooling fan. The flexibility is also provided by the modules themselves. This means that the DXP channels of the TBEN-S can be used as input or output without configuration. Use of the modular I/O system on the test bench will also bring advantages for FutureE customers. "After all, our customers usually get involved in development themselves after we have handed over a system. They then also benefit from simply redrawing functions later or expanding the system." The system is handed over so that the customer can later run their own test scenarios via the LabVIEW interface. The user can then define these routines.

Summary

Managing Director Limmer is just as satisfied with the test rig project as he is with the I/O modules. "The requirements change with every customer. Sometimes we develop systems for a forklift truck, sometimes for a heating system or a portable generator. These are always different requirements, but we can all map them with the I/O modules. We value the modules very much for this. They make our work easier."

Customer | www.future-e.com

Ralf Moder is a sales specialist at TURCK