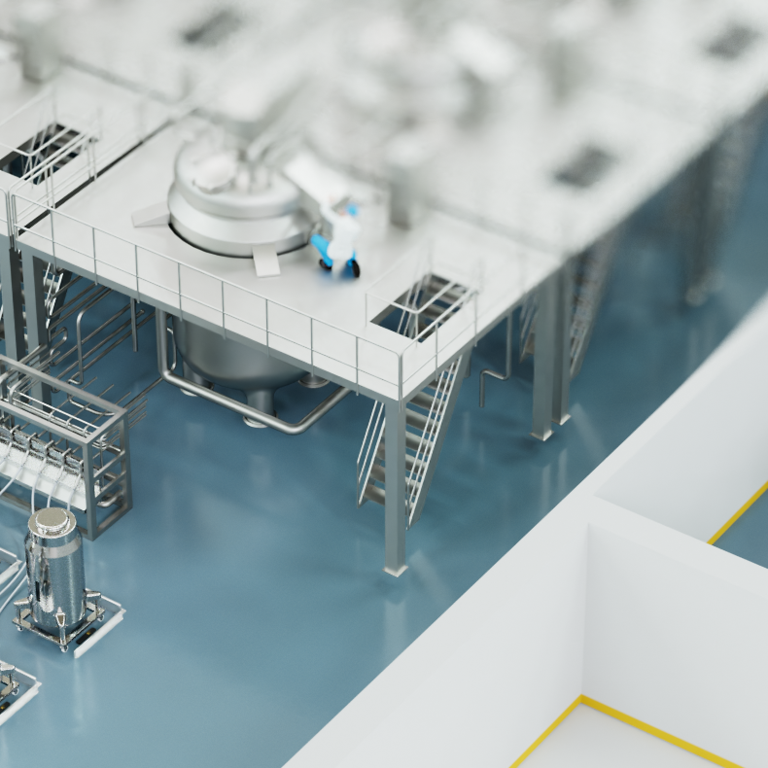

Challenge

In pharmaceutical and biopharmaceutical plants, numerous automation components must be installed securely and protected from environmental influences and cleaning processes. Standard solutions do not always perfectly match the individual requirements of the application. As a rule, there is little time for wiring in the plant. Assembling and wiring protective enclosures at the end customer's site

often

takes too long. In addition, the individual installation conditions are not always

suitable for

off-the-shelf protective enclosures.

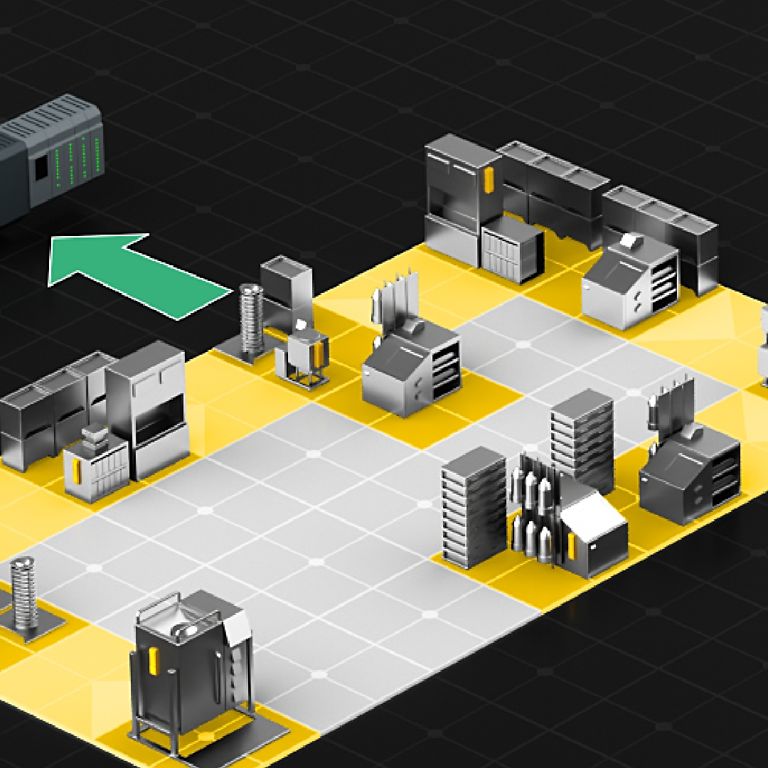

Solution

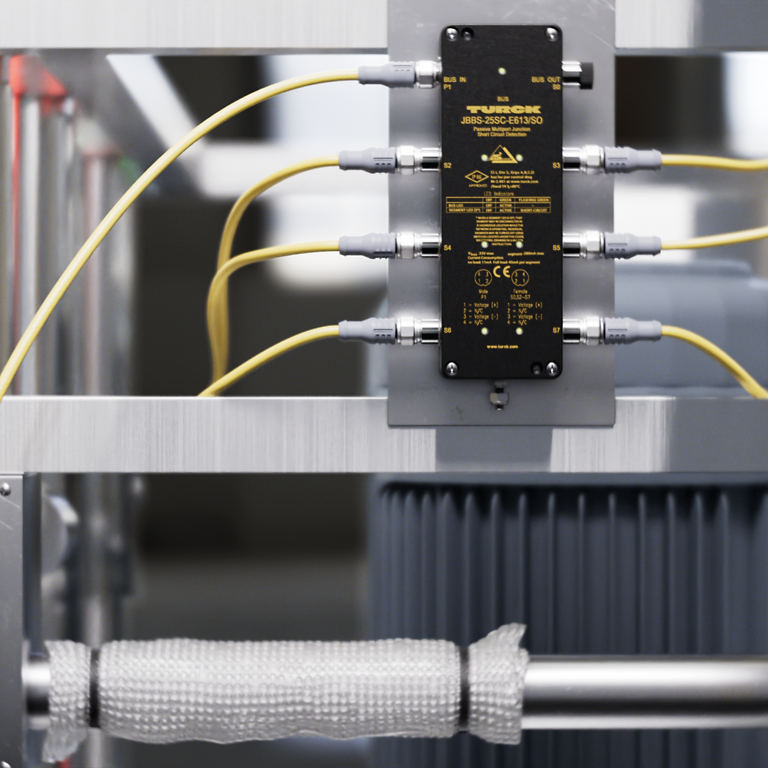

Many plant manufacturers and engineering service providers have defined standard loops for various sensor types and actuators such as valves. This is because there is little time to set up the plant. TURCK and its partners benefit here from the expertise of their in-house control cabinet manufacturer Turck

Mechatec

.

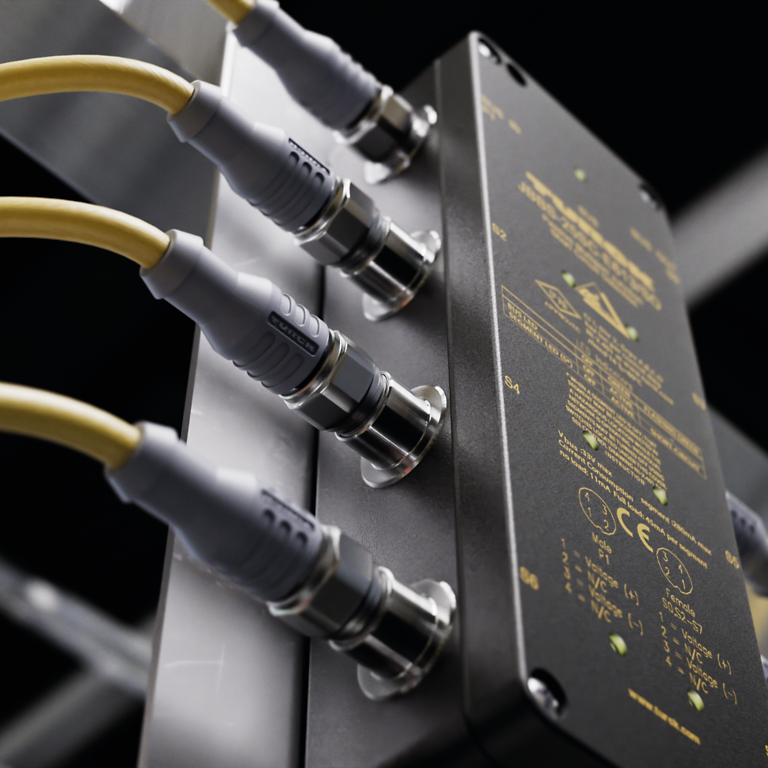

Turck

Mechatec

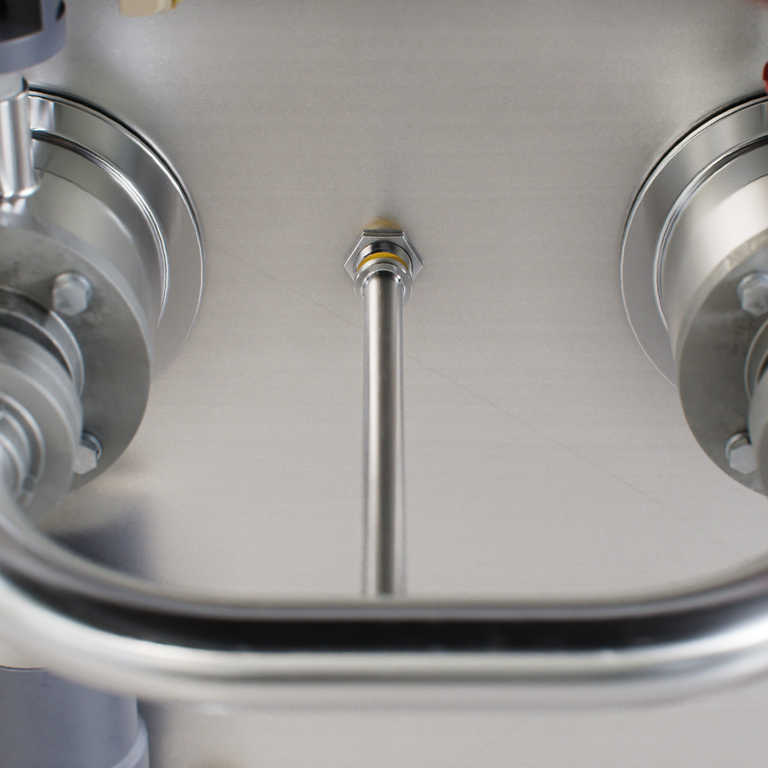

manufactures the desired components ready for connection in customized protective enclosures for the safe and efficient integration of fieldbus components in pharmaceutical plants. The aluminum or stainless steel enclosures are equipped with plastic or stainless steel cable glands. They offer protection against moisture, dust, and mechanical influences, ensuring that sensitive fieldbus devices operate reliably.

Customers benefit from comprehensive planning, with protective enclosures tailored precisely to their requirements. In addition to the actual fieldbus components, distribution stations, power supplies or surge protection can also be integrated. This ensures fast, clear and standard-compliant installation. Plant manufacturers and operators receive a highly reliable solution that optimally meets their requirements. For applications in hazardous areas, Turck

Mechatec

is authorized to implement intrinsically safe solutions.