Turck Vilant Systems supports customers from consulting and process analysis through solution development to installation and commissioning. Customers benefit from over 20 years of experience with complex processes and sophisticated software solutions that are customized to their individual needs.

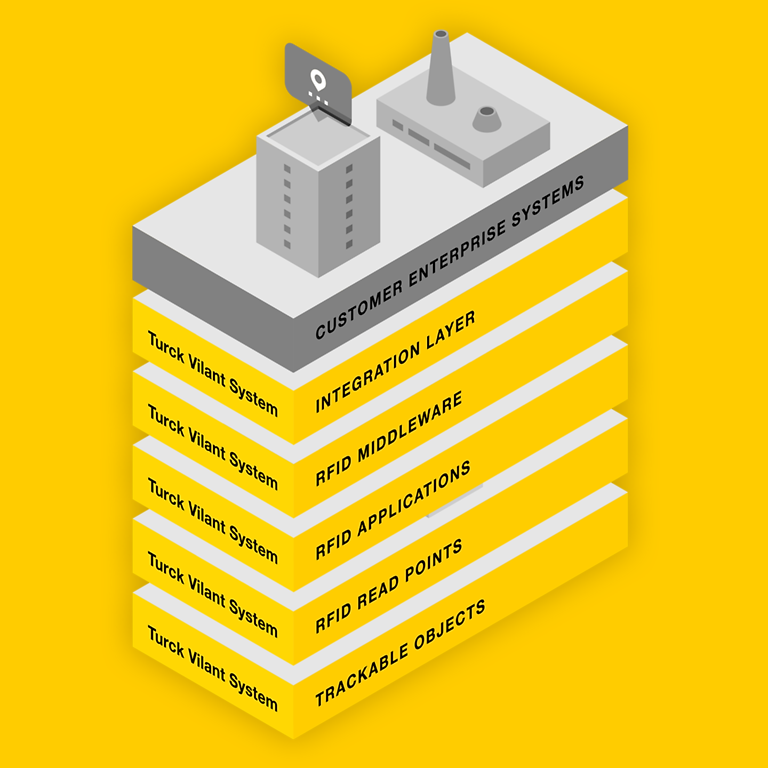

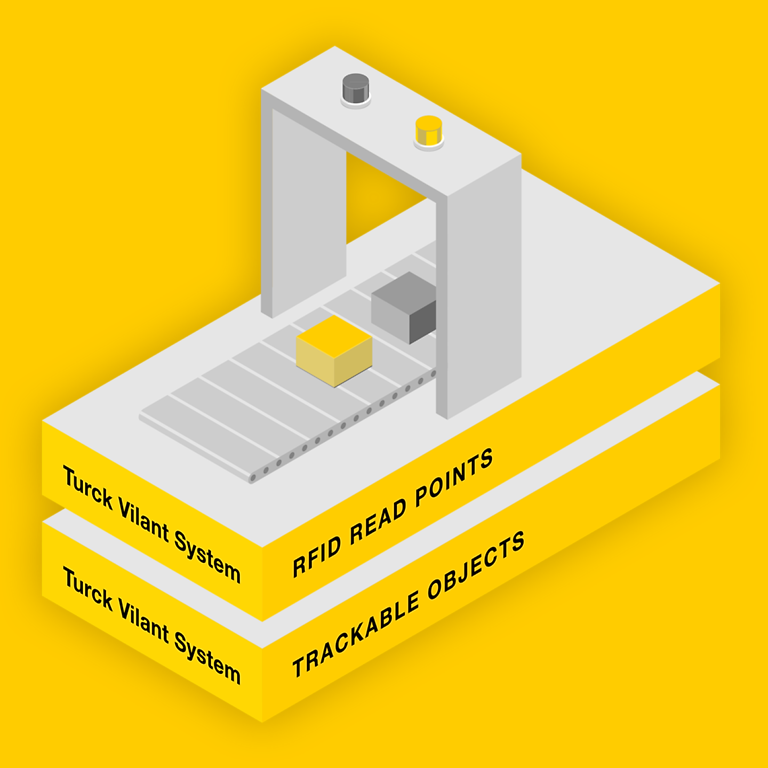

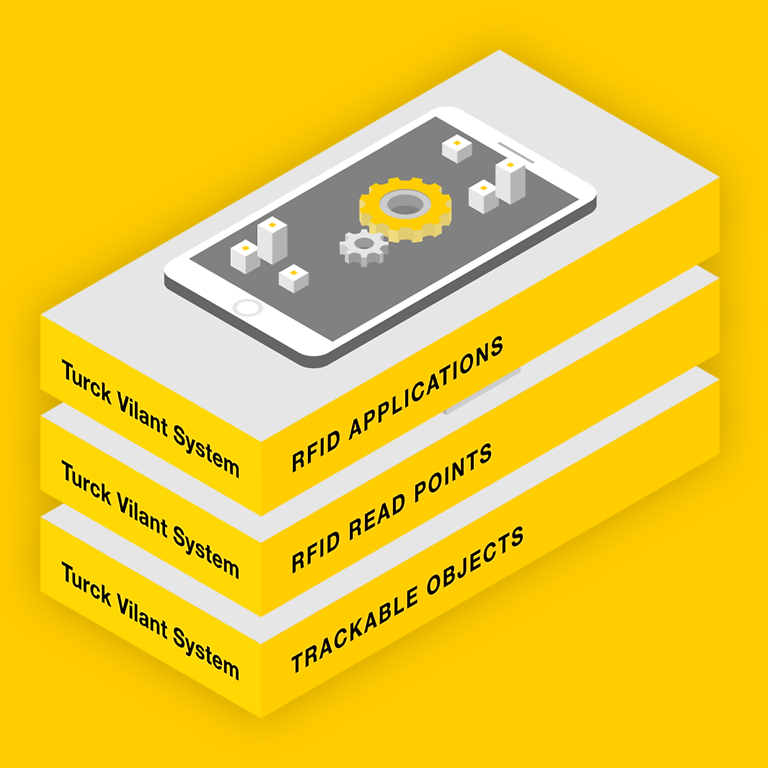

The TVS track-and-trace platform offers an intelligent RFID system that enables forklifts, mobile devices, or conveyor technology to reliably record documents, materials, products, containers, or pallets. The solution complies with GS1 standards and provides ready-to-use components for common RFID applications. It can be optionally expanded to include active tracking technologies such as BLE, GPS, or other IoT devices.

RFID middleware connects different reading points, while a local or cloud-based RFID server enables data mining, system management, and integration into enterprise IT systems such as ERP and WMS. This allows work areas, storage zones, loading ramps, vehicles, and devices to be consistently tracked with RFID and monitored in real time.