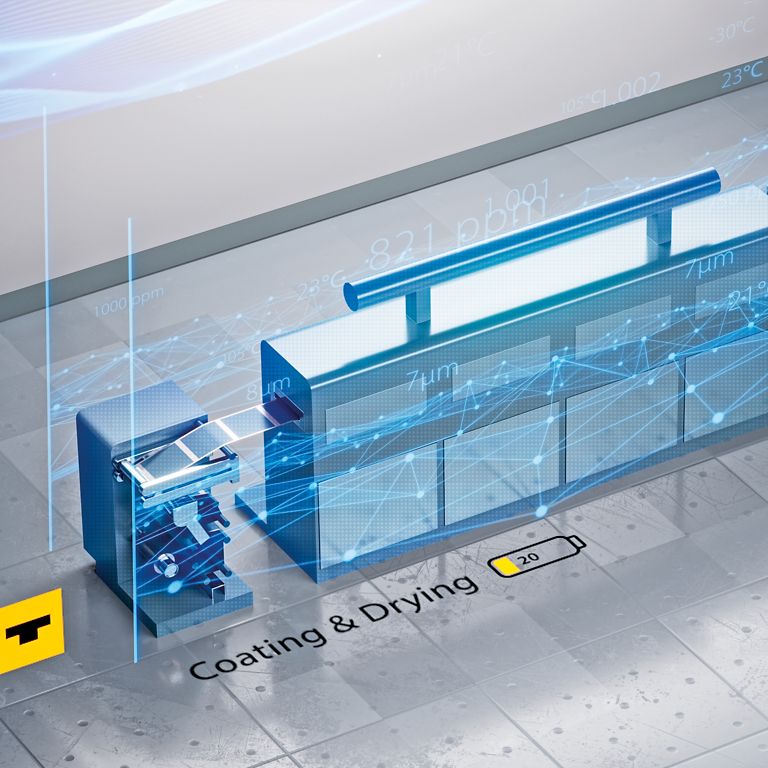

Robotic assembly of windows and attachments

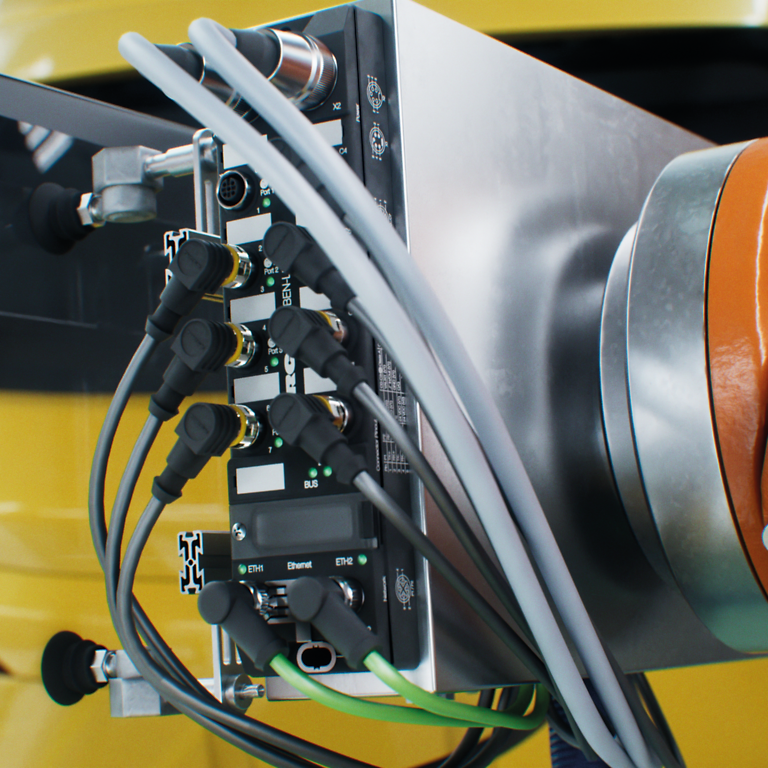

Block I/O modules speed up tool changes around the world in PROFINET, Ethernet/IP and Modbus TCP networks

Benefits

Space-saving design and quick installation

TURCK's multiprotocol allows one module to be used in PROFINET , EtherNet /IP and Modbus TCP networks

With Fast-Startup/Quick-Connect feature for applications with tool changes

Challenge

In vehicle final assembly, robots install windows, doors and attachments with high precision. Short cycle times are key to achieving production targets. For example, when changing tools, control components must be ready for use almost instantly to avoid delays. The modules must also be compatible with different Ethernet protocols to enable the same automation technology to be used worldwide.

Solution

TURCK's block I/O modules enable highly dynamic and standardized automation in vehicle final assembly. With ultra-fast startup times of just 150 ms in Fast-Startup mode (PROFINET ) and 90 ms in Quick-Connect mode (EtherNet/IP), the devices minimize downtimes during tool changes and significantly increase the productivity of the robot stations.

The robust design of the modules makes them highly resistant to vibrations, temperature changes and other industrial loads, which is ideal for continuous use in demanding production environments.

Another key feature is their multiprotocol functionality. The modules support PROFINET, EtherNet/IP and Modbus TCP in parallel without manual configuration. This enables standardized solutions to be implemented worldwide, which simplifies both commissioning and spare parts inventory.

"Our block I/O modules are fast, robust and can be used worldwide. They are the key to maximum efficiency in final assembly."

Aurel Buda | Director Product Management Factory Automation Systems | TURCK GmbH