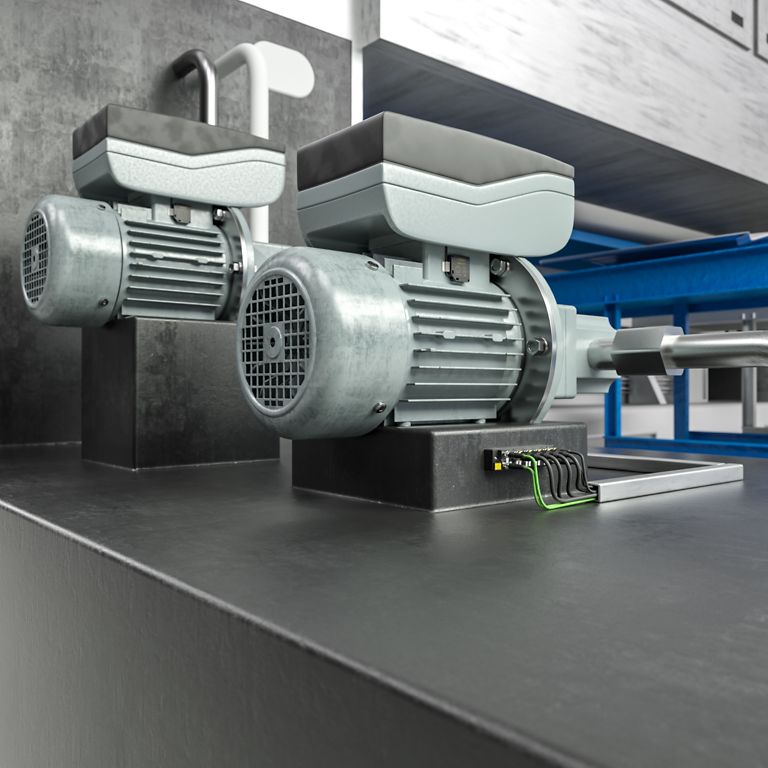

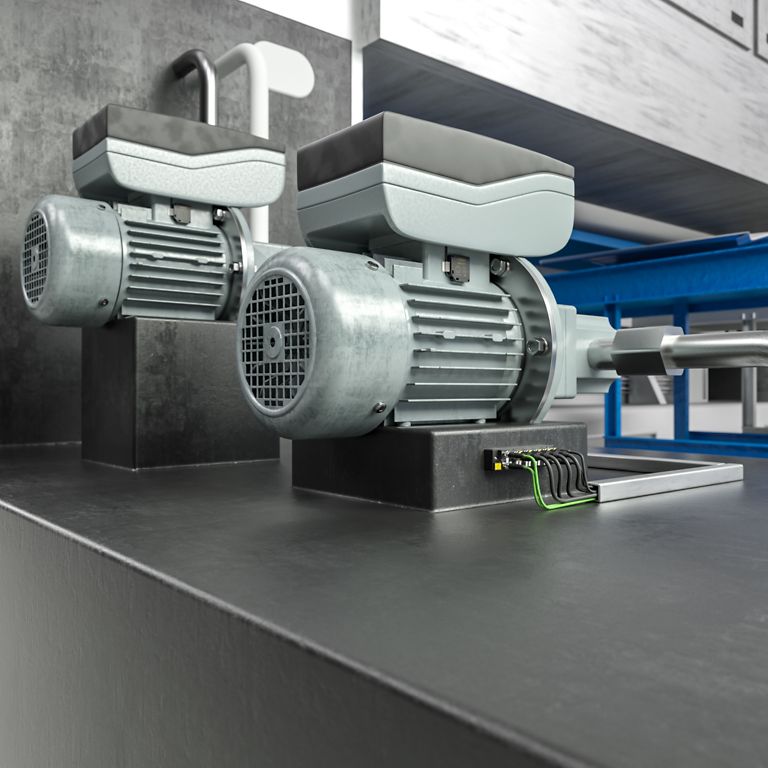

Motor control with condition monitoring

TBEN-S-2COM compact I/O module transmits process and status data via the same Ethernet cable

Benefits

- Higher machine availability due to timely warnings of impending damage

- No additional wiring thanks to communication via existing Ethernet cables

- Parallel query with lower priority avoids interaction with the machine controller

- Decentralized integration of motors with serial interfaces into Industrial Ethernet networks

Challenge

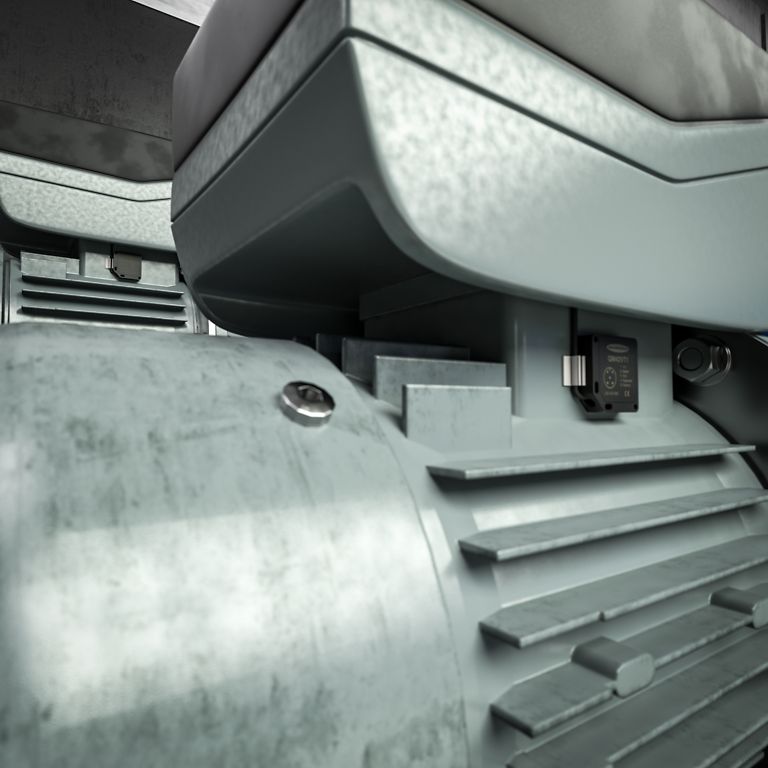

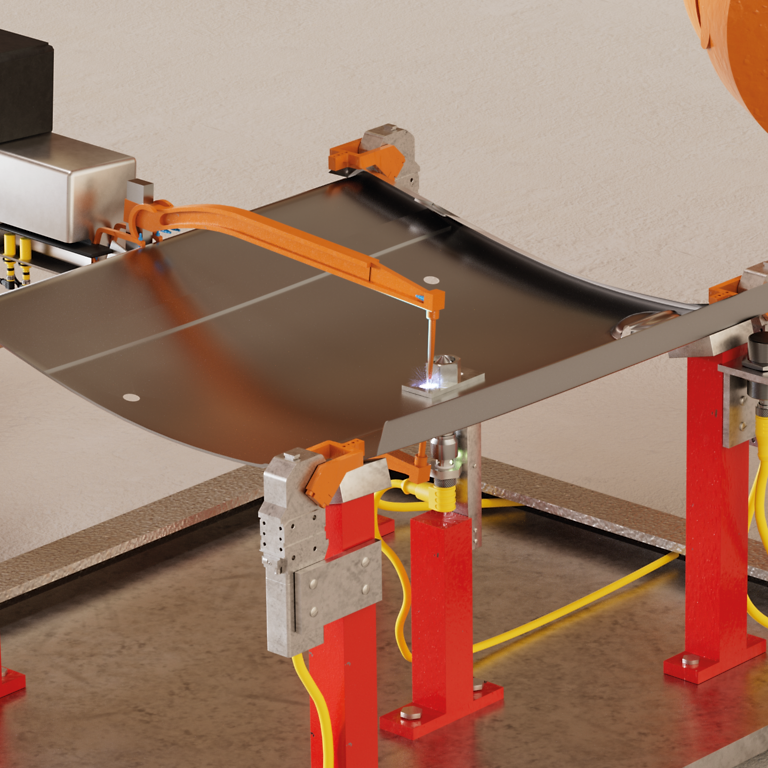

When controlling motors, both process data for operation and status data for condition monitoring must be transmitted efficiently. Vibration sensors provide valuable information about anomalies such as imbalance or bearing damage, which must be detected at an early stage. The challenge is to provide this data in real time without the need for additional network interfaces or complex hardware in order to ensure continuous machine availability.

Solution

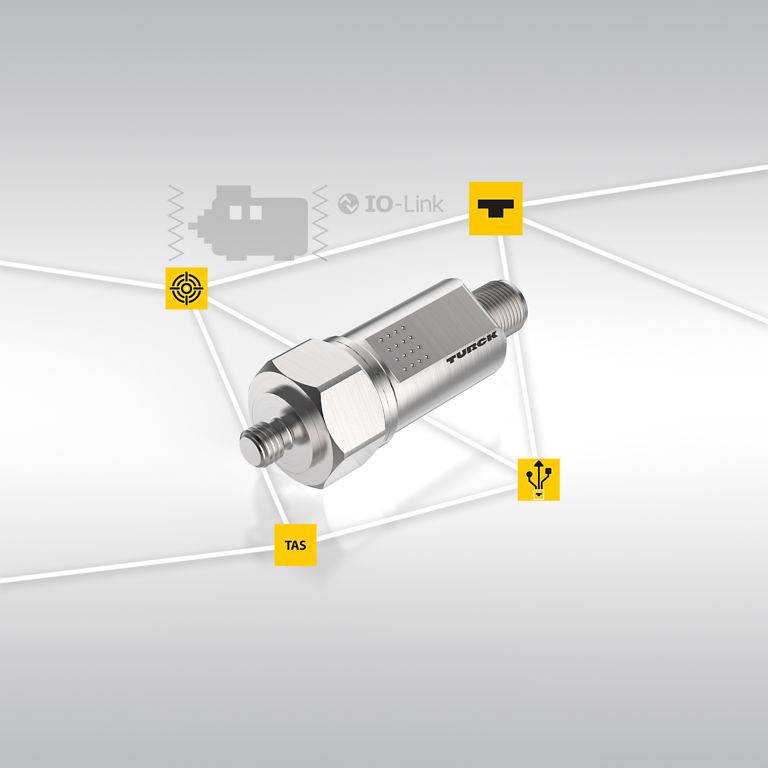

The compact TBEN-S-2COM I/O module combines motor control and condition monitoring on a single Ethernet line. Vibration sensors such as the QM30VT2 record vibration and temperature values and send them to the I/O module. At the same time, the module transmits process data from the PLC to the motor – either via RS485 or RS232.

Thanks to multi-protocol technology, TBEN-S-2COM communicates simultaneously with controllers, HMIs or cloud applications. Motor control remains prioritized, while vibration data is transmitted with lower priority, ensuring reliable data transmission.

For further analysis, the recorded status data can be pre-processed via edge controllers such as the TX700 or forwarded directly to cloud systems via MQTT or OPC-UA. Individual dashboards visualize the data and proactively inform maintenance personnel when limit values are exceeded. This reduces downtime and enables predictive maintenance planning – for efficient and reliable machine monitoring.

"We can efficiently combine standard motor control and condition monitoring in a single solution. Our TBEN-S2-2COM-4DXP module ensures reliable production with minimal installation effort."

Nitsche Frederik | Product Manager Factory Automation Systems | TURCK GmbH

Learn more about our products