Access control with RFID system

TURCK's IO-Link RFID system ensures high-voltage tests at the Belgian railway SNCB

Quick read

To ensure safe working conditions, companies must ensure that only persons with the appropriate training are allowed access to certain areas and facilities. The Belgian railway company SNCB uses an RFID system from TURCK to monitor access to the high-voltage test areas of its central workshop in Mechelen. There, train sets are maintained, rebuilt and overhauled. In a new laboratory, SNCB tests the power converters of the trains at 3000 volts.

"The risks of a 3000 V installation should not be underestimated," says Kristof Honee, responsible for the electronics department at the central workshop of the Belgian railway SNCB in Mechelen. "Even if the voltage is switched off, there may still be charge in the coils and capacitors. That is why the work must always be carried out systematically, according to established procedures and by people who are aware of the risks." In Belgium, the overhead lines for the trains have a DC voltage of 3000 volts. Converters in the trains convert the high voltage into lower voltages for the drives, the air conditioning system and all other devices.

Laboratory power supply supplies 3000 volts

"In the new laboratory, we have three test areas to test the converters after an overhaul or repair," says Honee. "Many components can be tested with lower voltages, but for the final test we use a laboratory power supply that can supply 3000 V, just like the overhead line." The tests must be carried out according to strictly regulated procedures, with great attention being paid to the safety risks.

SNCB commissioned Belgian system integrator Dymotec – specialized in industrial electrical installations and automation – to develop a system that is able to manage the test procedures and control access, taking all the required safety aspects into account. It is crucial to manage permissions and track all operations.

RFID Read/Write Heads and Display Lamps

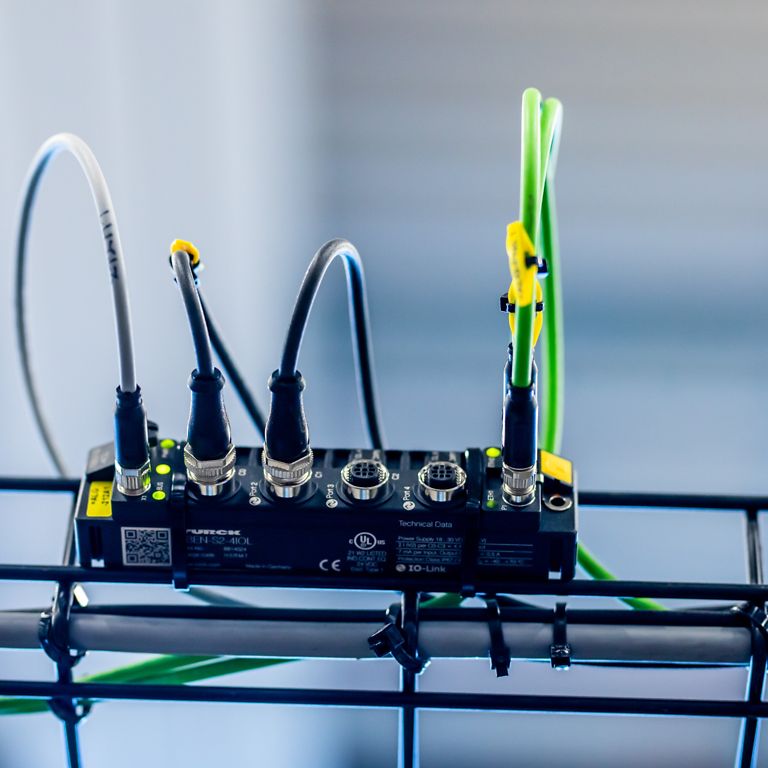

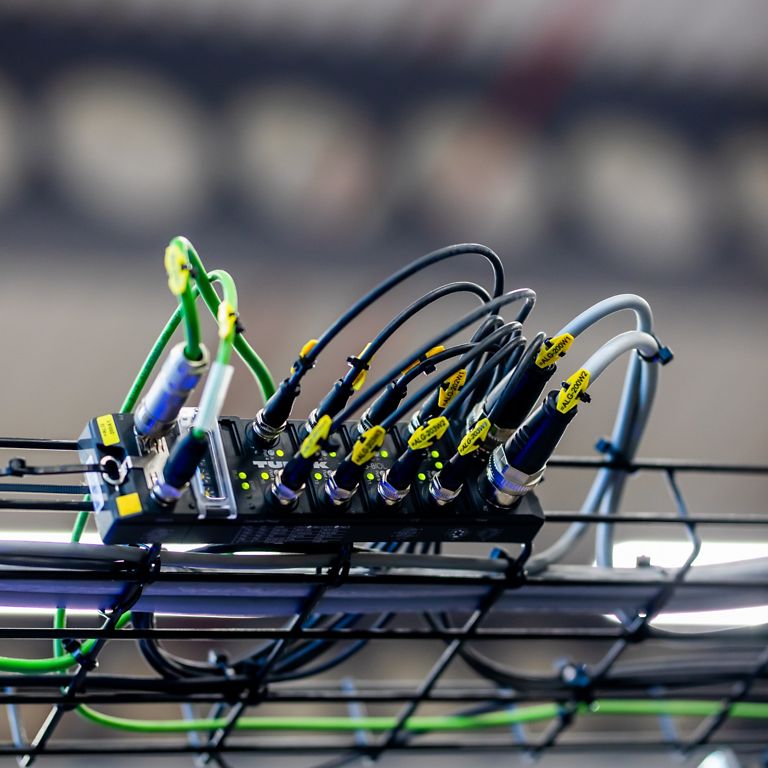

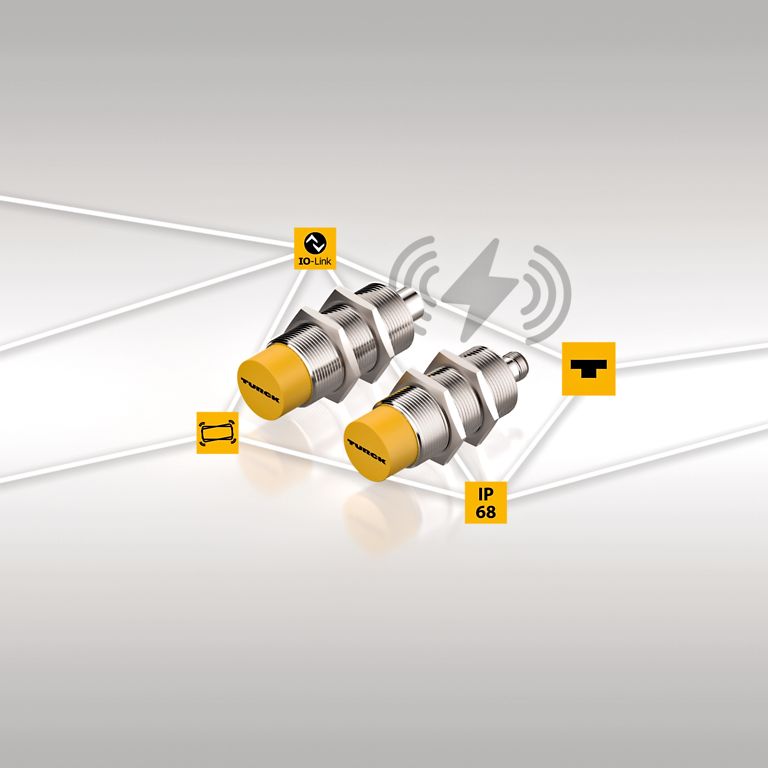

Dymotec uses the RFID system from TURCK for this purpose. The RFID read/write heads read in the ID of a card and transfer it to the PLC via IO-Link. "The RFID system can be implemented very easily," says Jimmy Volders, project manager at Dymotec. "The RFID readers and the signal lamps are connected to the IO-Link master via IO-Link. These also provide the power supply, so that a lot of cabling is not required."

The TBEN-L5-8IOL IO-Link masters communicate with the PLC via Profinet. The masters form a line topology via the integrated two-port switch of the IO-Link modules, meaning that only one Profinet line needs to be routed from access door to access door, which in turn saves cabling work.

The test areas are equipped with Banner Engineering K50 signal lamps, which are controlled by the PLC to change their color. In contrast to conventional color tower lights in rod design, one light per entrance door is therefore sufficient. Programming does not have to be limited to selecting a single color. The LEDs in the light can be controlled individually. The control units have been equipped with tower lights with a sound function, so that the system can also output acoustic warning signals.

Thanks to the automation of the test facility, all safety procedures are now implemented effectively – without slowing down the processes by means of manual processes. The complete traceability of each action is ensured throughout the process.

Customer | www.belgiantrain.be/de

Danny D’hollander is a sales specialist at Turck Multiprox in Belgium