Condition monitoring of cables thanks to M12Plus connectors

TURCK shifts cable condition monitoring directly to the connector itself — including wireless transmission of measurement values via Bluetooth Low Energy

Quick read

Faulty wiring and contact problems can lead to costly plant downtime and unplanned maintenance, and are among the most common causes of failure. TURCK's smart M12Plus connectors can now provide a solution and enable condition monitoring of the cable and contacts by measuring current and voltage. The cable is constantly being analyzed and drops in voltage can be identified at an early stage. Fault sources can be easily identified and located because each connector is assigned a unique address. This ensures smooth plant operation and prevents costly outages or unplanned maintenance. The M12Plus connector opens the door to a completely new approach to predictive maintenance.

Despite the development of wireless systems and communication links, the digital transformation of industry will continue to require secure wired connection solutions in the future. Given the increased adoption of the Industrial Internet of Things (IIoT), even smart and networked devices always require a reliable communication link and power supply. This means that connection technology also plays a crucial role in the digital transformation of industry.

TURCK has been expanding its portfolio for decades with a wide range of connection technology, from standard M12 connectors and splitters in countless variants to customer-specific cord sets. With numerous connection types and cable variants, TURCK's wide range of products offers flexible combination options that cover a large number of applications.

Technology for early detection of problems

Just as in other fields, connection technology is constantly evolving. One of the most recent innovations in this field is TURCK's M12Plus, an M12 connector with integrated voltage- and current-monitoring electronics, which was developed in cooperation with IMS Connector Systems and Fraunhofer EMI. The M12Plus connector shifts the condition monitoring of highly stressed cables directly to the connection technology.

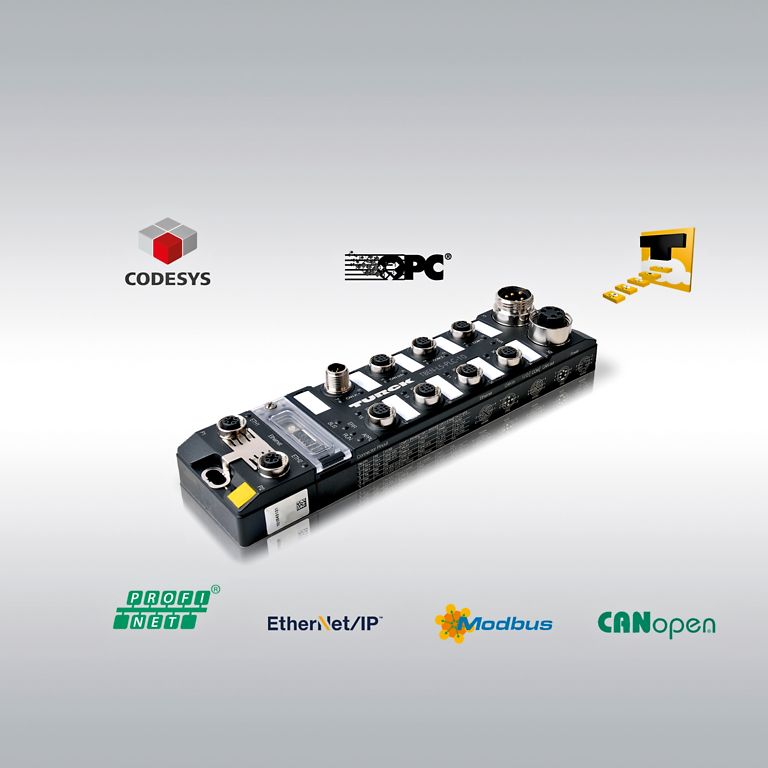

In addition to the measurement electronics, the M12Plus also has a Bluetooth chip on board. This allows the connector to measure voltages and currents and send these measurements to a data interface in the plant, for example to the TURCK TBEN-PLC. A Bluetooth dongle enables the robust IP67 controller to read a wide range of Bluetooth -enabled devices, with application-specific polling intervals to ensure optimum performance. The data pertaining to the cables is transmitted to the controller in real time. This information can be used for purposes such as identifying potential problems—including voltage drops in the cable or plug contact—before the connection actually fails. If necessary, the controller can be programmed to trigger an alarm when a certain threshold is reached.

Effective protection against cable failures

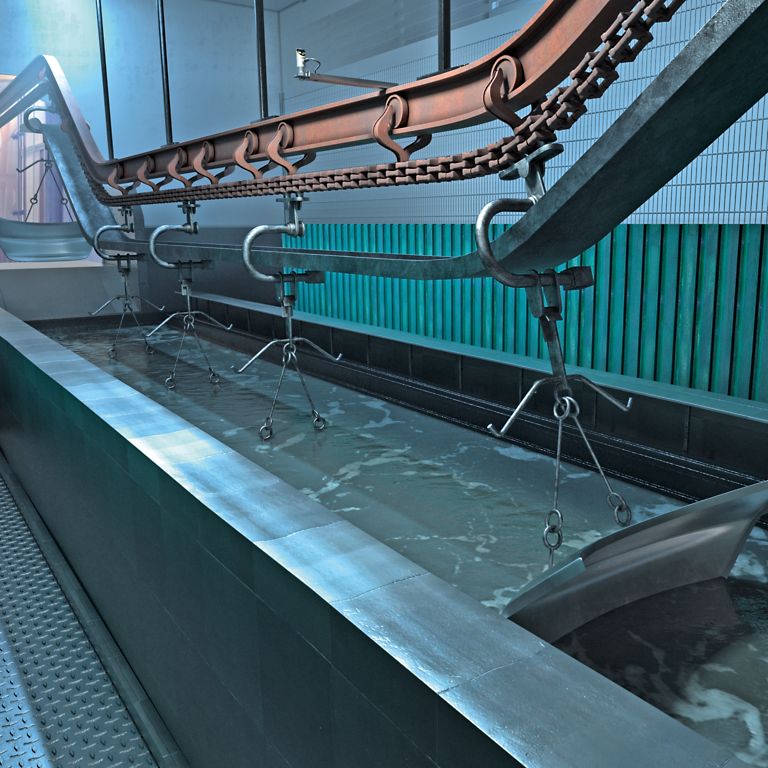

In applications in which cables in drag chains or on robots are repeatedly bent, copper is more likely to degrade over time. The millions of tensile and compression loads in these applications impair the copper quality, which can lead to breaks in cores or stranded wires.

The intelligent M12Plus connectors with integrated measurement electronics consist of a 4-wire, flexible cable (4 × 0.34 mm²) from the TXL product series with a polyurethane outer jacket, which is intended for use in drag chains. A-coded M12 connectors are fitted at both ends of the sensor/actuator cable. This design complies with the common standard used in many industrial plants.

The sensors installed in the M12Plus connectors enable voltage and current to be measured at the male connector and the female connector. In this way, by comparing input and output values, impairments such as cable kinks, cable breaks or insufficient power supply can be detected at an early stage. These high-precision measurement values also enable precise monitoring of contact quality, ensuring long-lasting and reliable performance of the connection technology. Factors such as corrosion of contacts or wear caused by repeated plugin processes are taken into account.

Optimization of plant availability through precise location of cables

In a plant with thousands of connections, there is clearly a major problem: If a cable connection fails, a technician must first locate the fault on site — and of course do so as quickly as possible in order to minimize the financial losses caused by the plant's downtime. Such troubleshooting is far more complex in IP67 connector technology than in control cabinet wiring.

TURCK's smart M12Plus connector remedies this problem and offers a decisive advantage in terms of locatability: The individual MAC address of each M12Plus connector means that the cable at risk of failure can be directly identified using the plant documentation. Without wasting valuable time searching, a technician can now go to the plant with the appropriate spare part at a chosen time and directly replace the affected cable so that the plant can continue operation without unplanned downtimes.

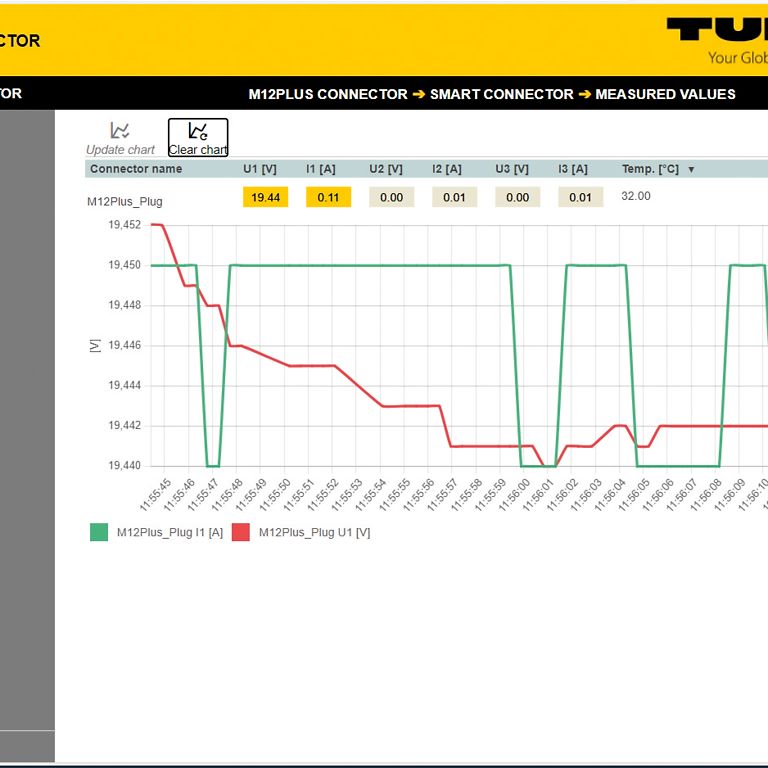

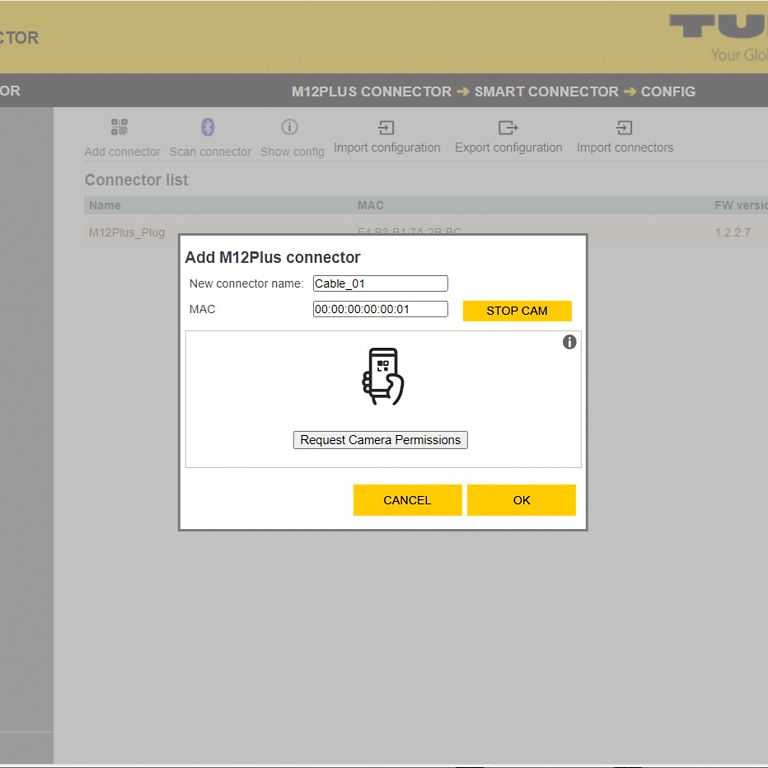

Configuration via the TURCK Automation Suite

The M12Plus connectors can be configured and the measured values visualized conveniently using TURCK's IIoT and service tool TAS (TURCK Automation Suite). To support this, the browser‑based toolkit has been extended to include the required functionalities in the latest release. For example, each M12Plus can be given an individual designation via TAS. If a specific connector needs to be located within a plant, it can be made to flash with just a click. The current and voltage values that are present can also be retrieved via TAS at the click of a mouse.

Outlook

The M12Plus now being showcased is the first model in a new generation of smart connectors that are conceivable in numerous other variants and can be tailored specifically to individual requirements. This includes further developments such as application-specific designs, cables with different cross-sections, varying numbers of cores and a wide range of voltage ranges.