Mobile Equipment

Automation solutions for mobile machines: robust, smart, networked

Intelligence and ease for heavy machines

How can machines become smarter and yet easy to operate and resistant to damage?

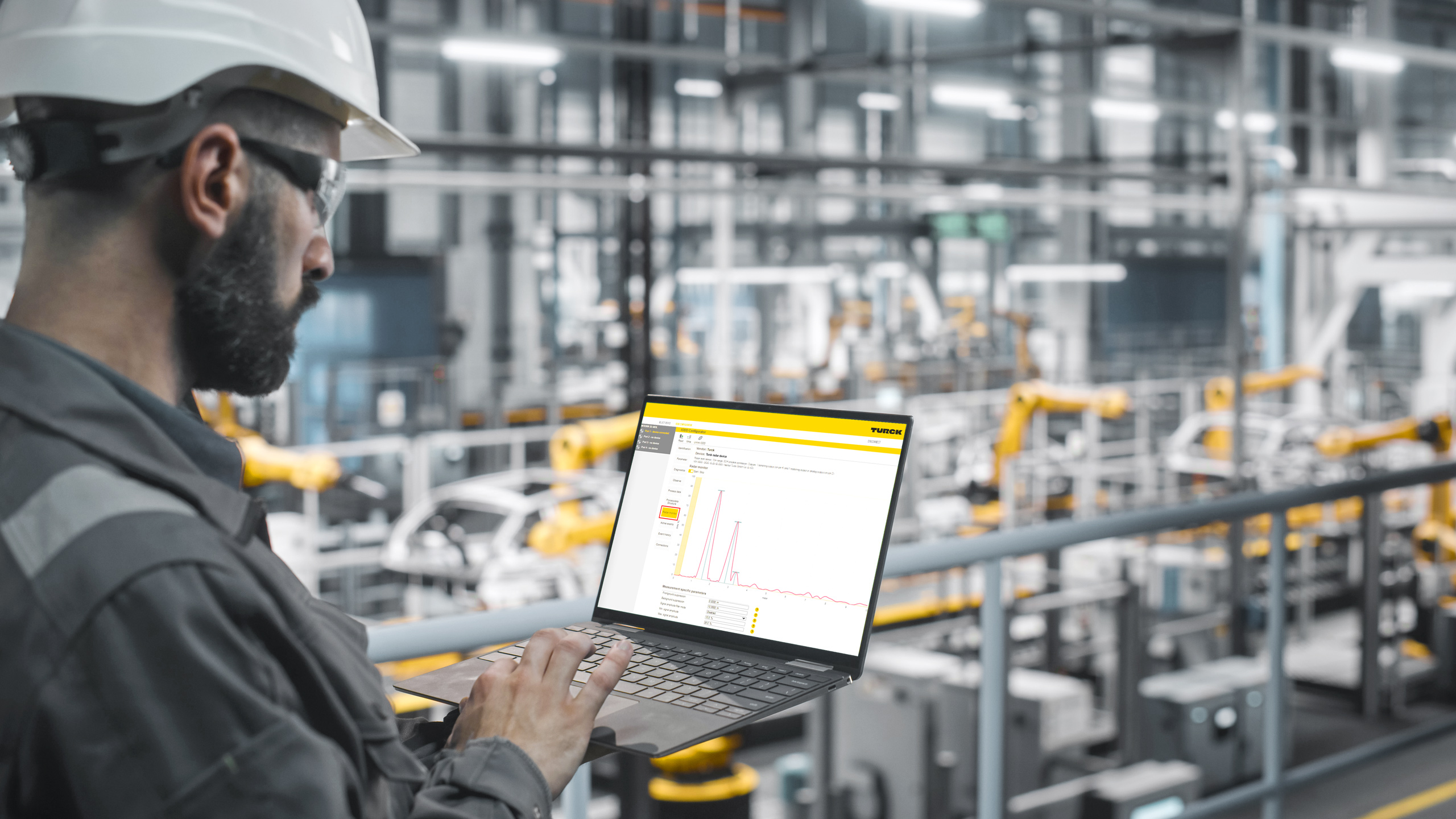

With robust automation solutions that enable data integration, diagnostics, and control in the machine or via the cloud. With smart sensors and I/O modules that detect critical changes at an early stage, and with special connectivity for mobile machinery.

Solutions for mobile equipment

See the advantages that TURCK solutions offer in mobile equipment: data-driven and digitally networked for maximum availability and smart processes.

Find your solutions

Automation solutions and products from TURCK increase the availability and efficiency of your machines and systems in numerous industries.

Insights for mobile machinery

Discover relevant content for your industry, from trends and best practices to efficient automation approaches and innovative technologies that make processes more transparent, flexible, and secure.

Autonomous asparagus harvesting robot

AvL Motion is breaking new ground with a machine for selective harvesting of white asparagus, packed with high-precision sensors as well as RFID and fieldbus technology from TURCK

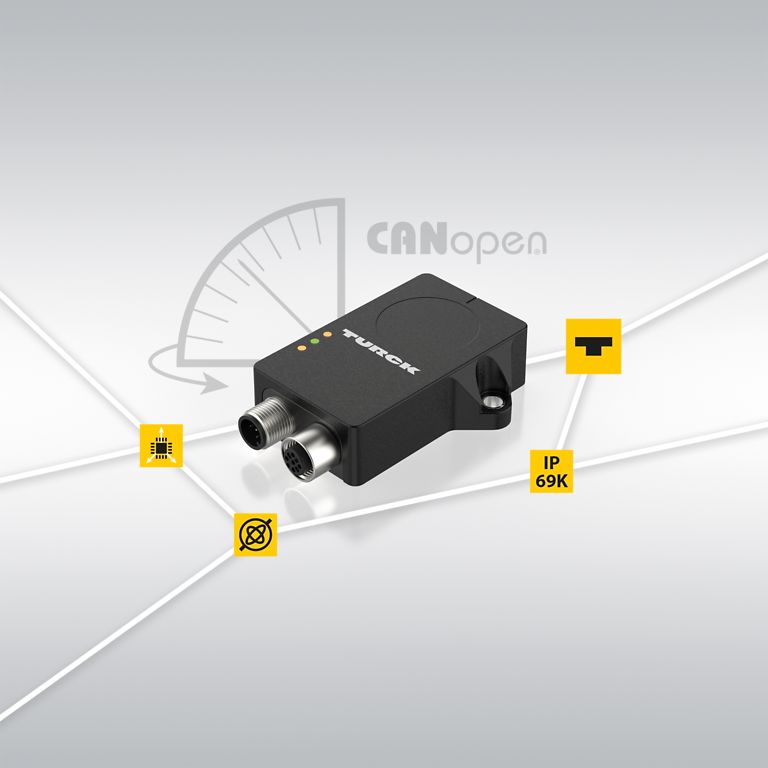

Inclinometer with CANopen interface

TURCK's MEMS/gyroscope sensors are available with a CANopen interface for mobile machines

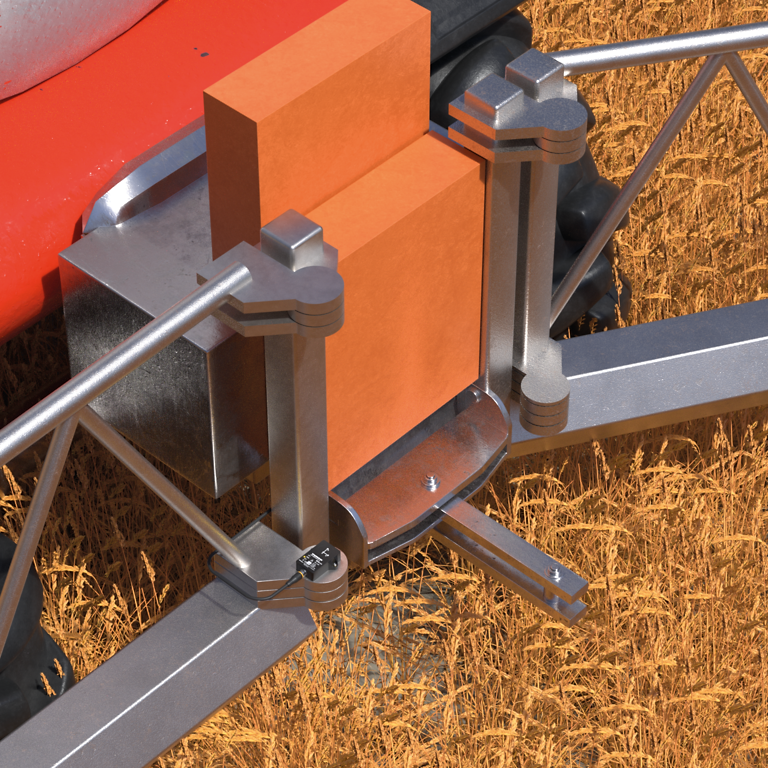

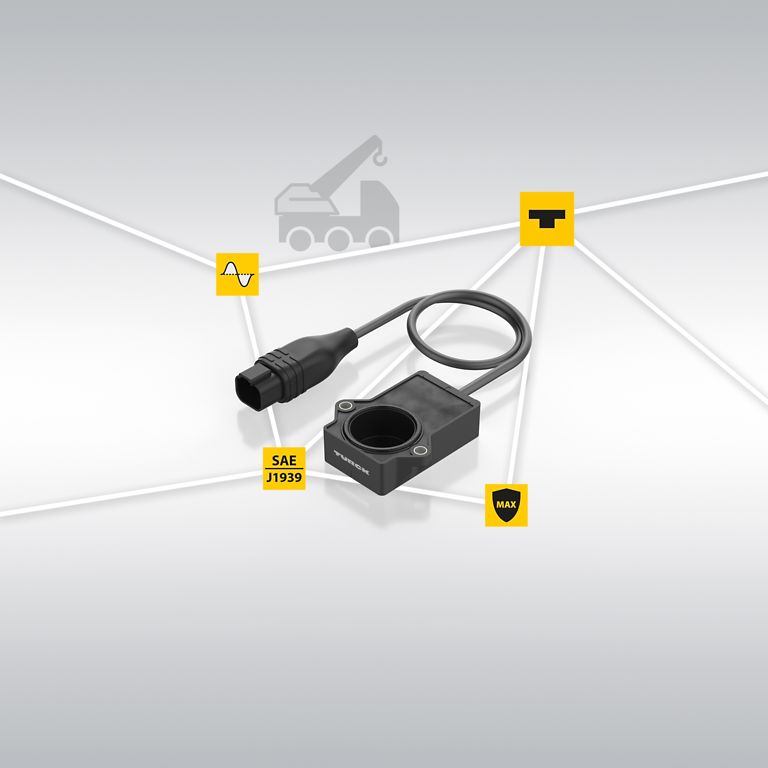

Robust angle measurement for mobile equipment

TURCK's robust QR20 sensors with SAE-J1939 and Deutsch connectors guarantee reliable angle detection on mobile equipment

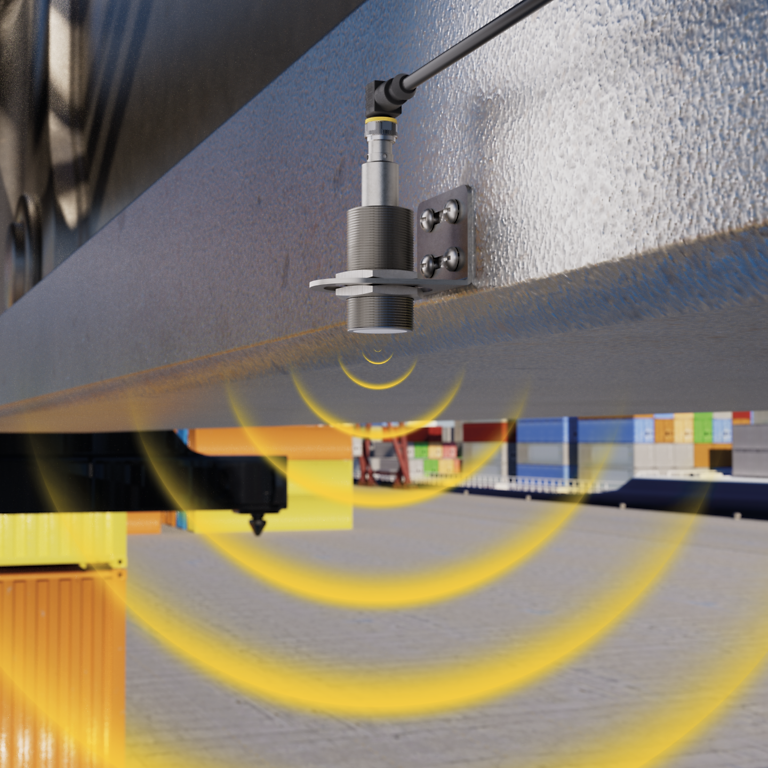

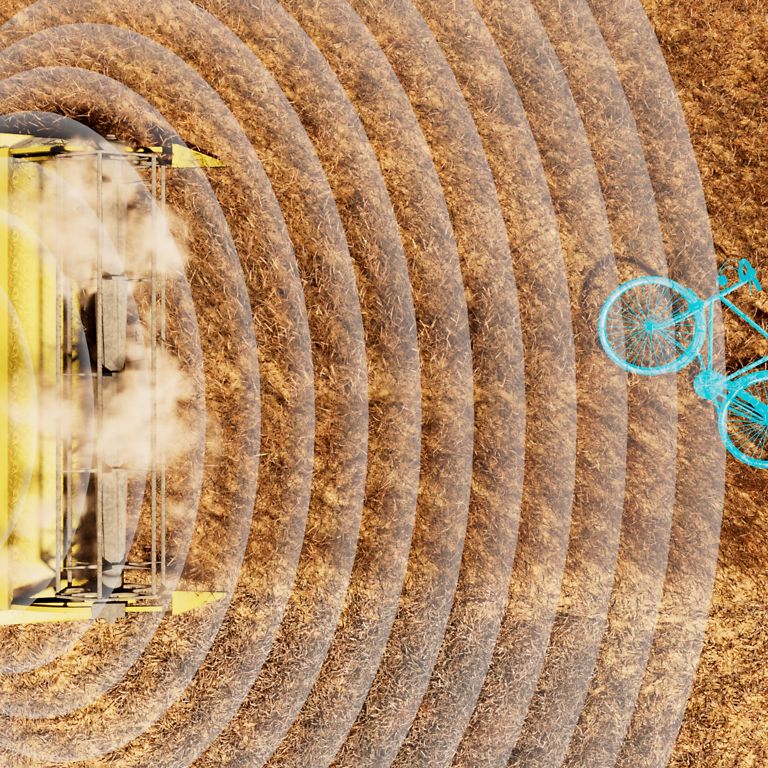

Radar sensor for 3D object detection

TURCK's MR15-Q80 3D radar scanner ensures reliable object detection and collision avoidance: from mobile work machines to intralogistics

Maximum machine availability

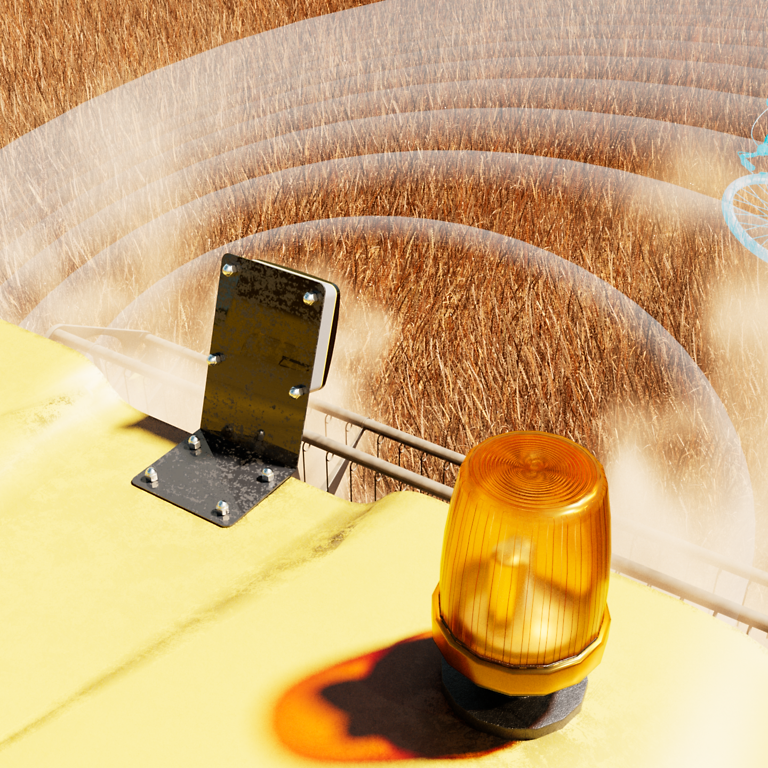

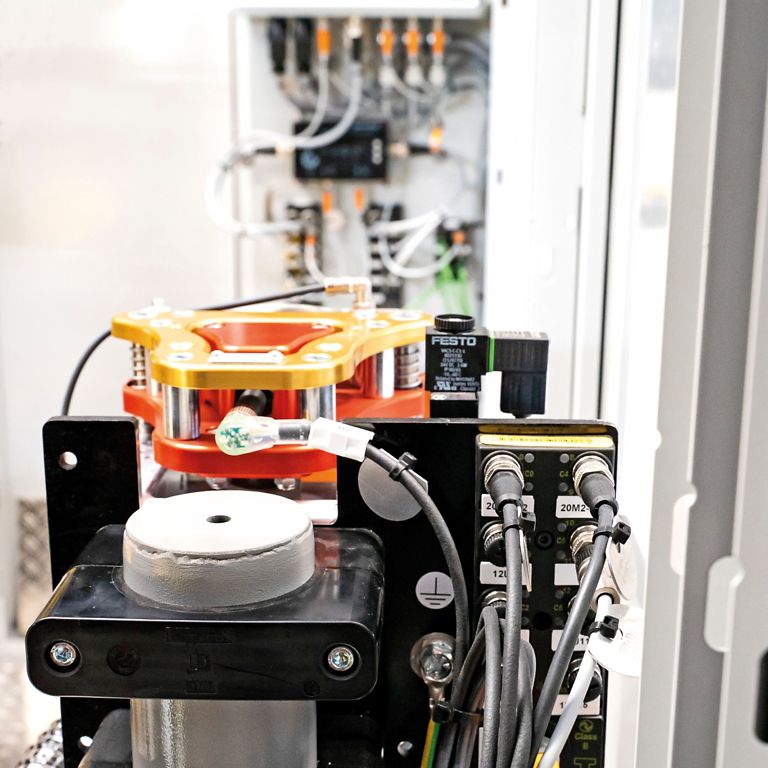

Robust, fully encapsulated solutions ensure the availability of your device

Speak the language of industry

Solutions with CANopen, SAE J1939 or fully encapsulated Deutsch connectors are in demand.

Efficient data integration

Sensor and I/O solutions with IO-Link supply valuable data for condition monitoring and predictive maintenance.