Automotive

Automation solutions for automotive production: robust, smart, decentralized

Whether in evolution or architecture: in the end, it's flexibility, not size, that counts.

How do your processes remain flexible, scalable and available despite the growing variety of variants and volatile supply chains?

With a partner who uses scalable I/O solutions to set up your plants in a modular and future-proof manner. A partner for the "out-of-the-box" means implementing automation even without control cabinets. A partner who speaks the language of the industry and is valued by automotive manufacturers, suppliers and integrators worldwide.

Solutions for automotive production

See the advantages that TURCK solutions offer in automotive production: data-driven and digitally networked for maximum availability and smart processes.

Find your solutions

Automation solutions and products from TURCK increase the availability and efficiency of your machines and systems in numerous industries.

Insights for automotive production

Discover relevant content for your industry, from trends and best practices to efficient automation approaches and innovative technologies that make processes more transparent, flexible, and secure.

Decentralized? Of course.

Security technology in particular offers many advantages when designed to be decentralized: offline testing and good scalability to name just two of them.

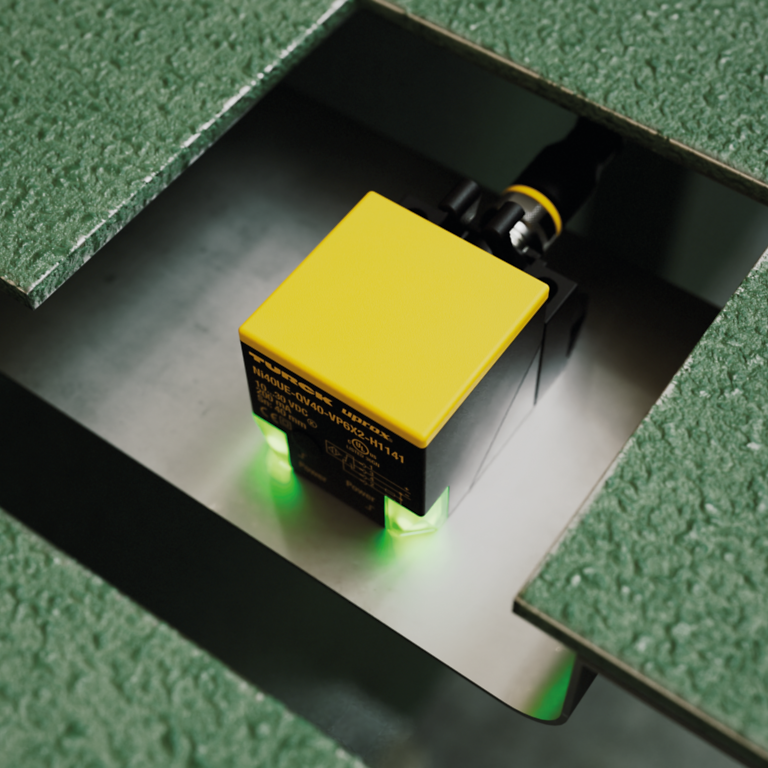

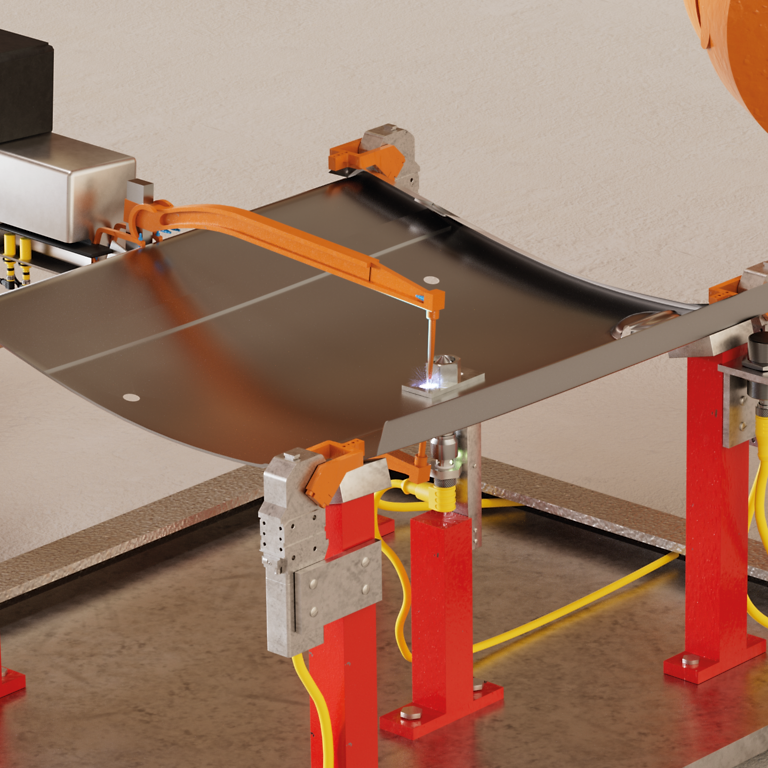

Weld nut sensor detects and fixes weld nuts

NIMFE sensors are the solution for high-performance spot welding applications.

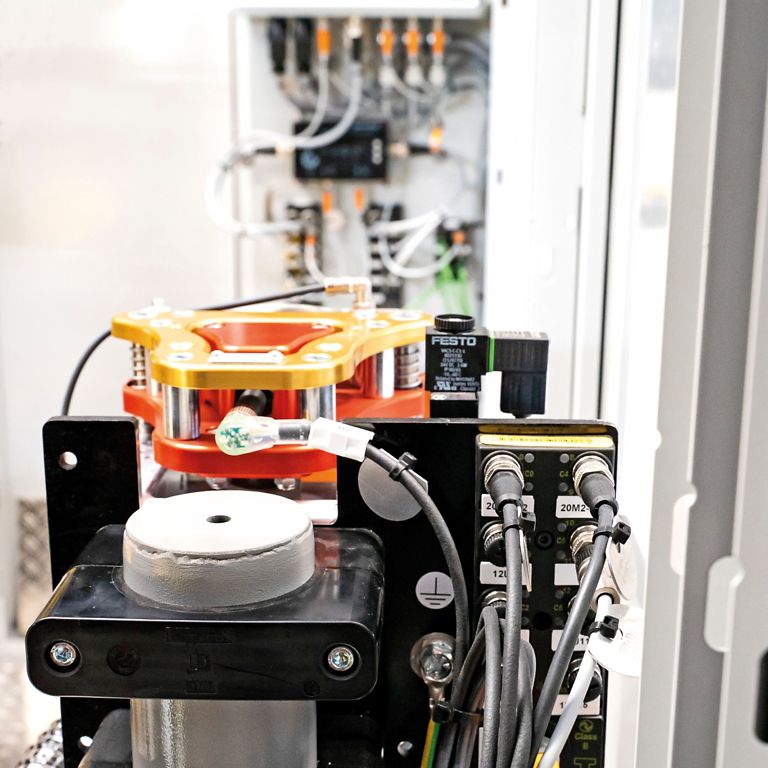

Decentralized safety technology for modular production

AWL-Techniek uses scalable safety technology directly on the modules, implemented with TURCK's IP67 IO-Link and safety I/O concept

Innovative Automation for Automotive Transformation (NEV)

Whatever the mobility of the future may be, TURCK smart automation solutions ensure efficient and flexible production.

Fast turnaround times

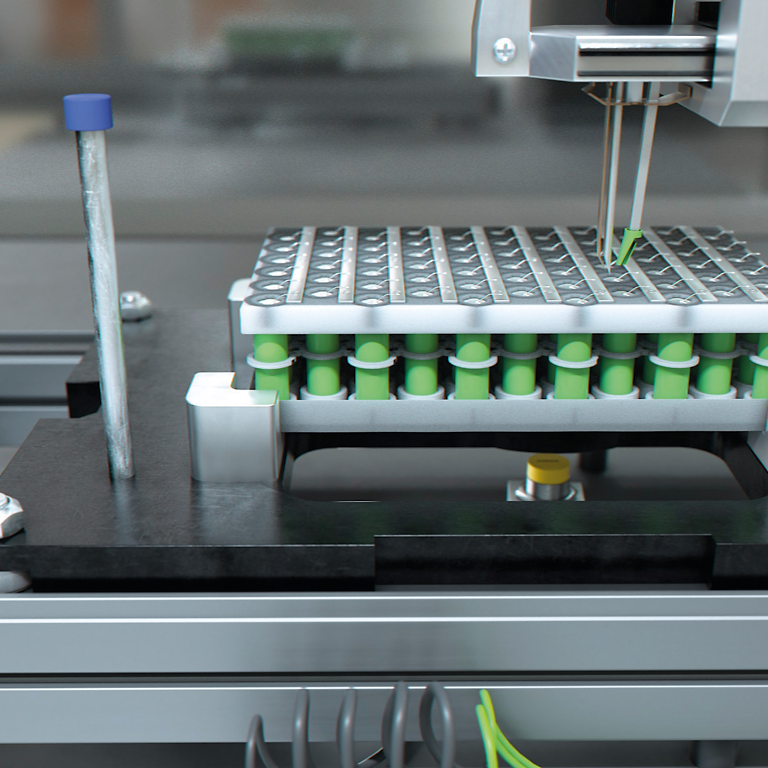

High-speed data communication, decentralized signal processing and control plus identification with RFID ensure a highly efficient flow of materials.

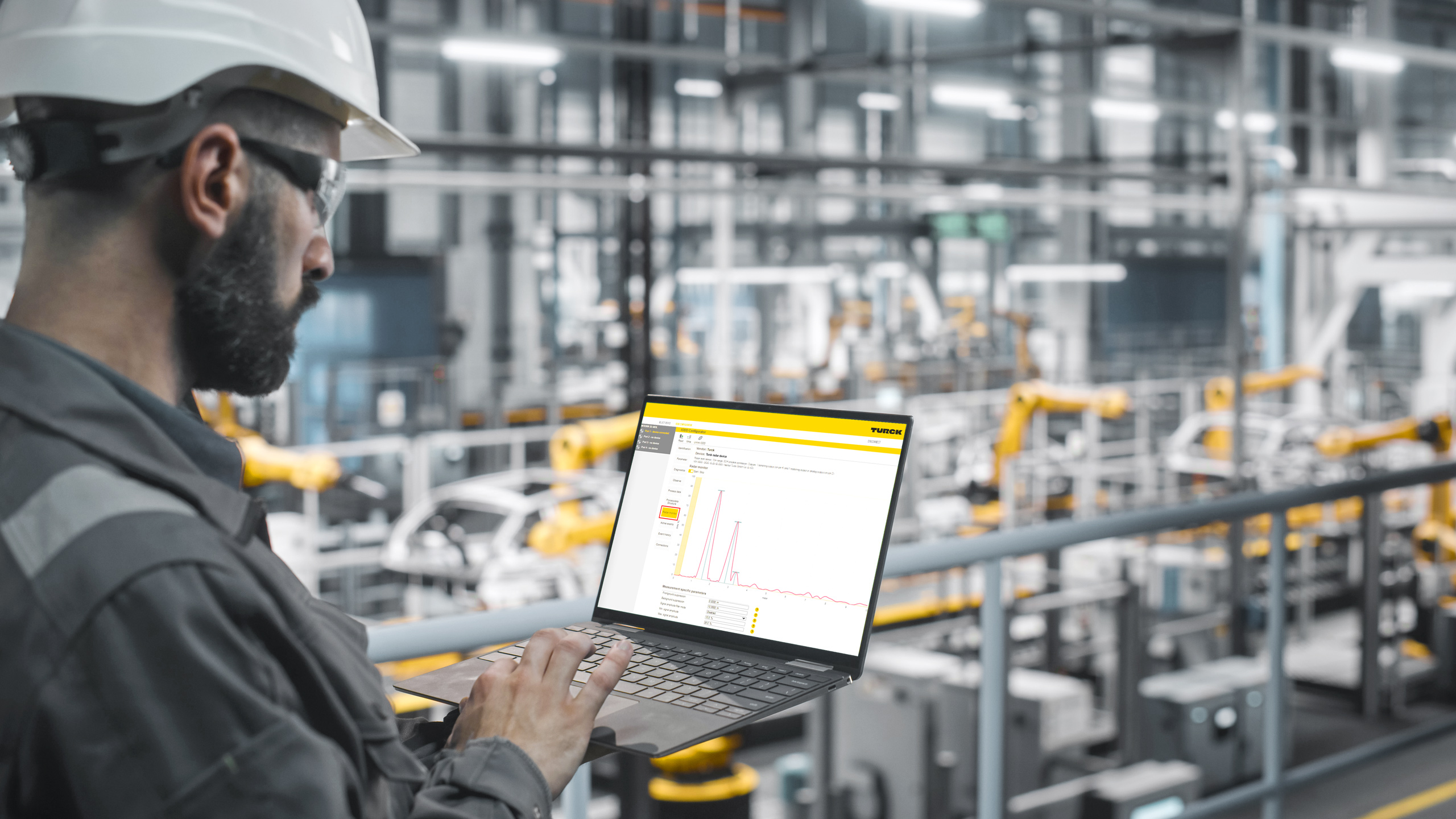

Maximum availability

Condition monitoring, predictive maintenance and robust sensor technology combined with IP67-rated I/O, control and identification technology prevent unplanned plant downtime.

End-to-end traceability

With track-and-trace systems ranging from tags to software, you have permanent access to every workpiece carrier, every product and every delivery.