Food and Beverage

Automation technology for food and beverage production: available, hygienic, transparent

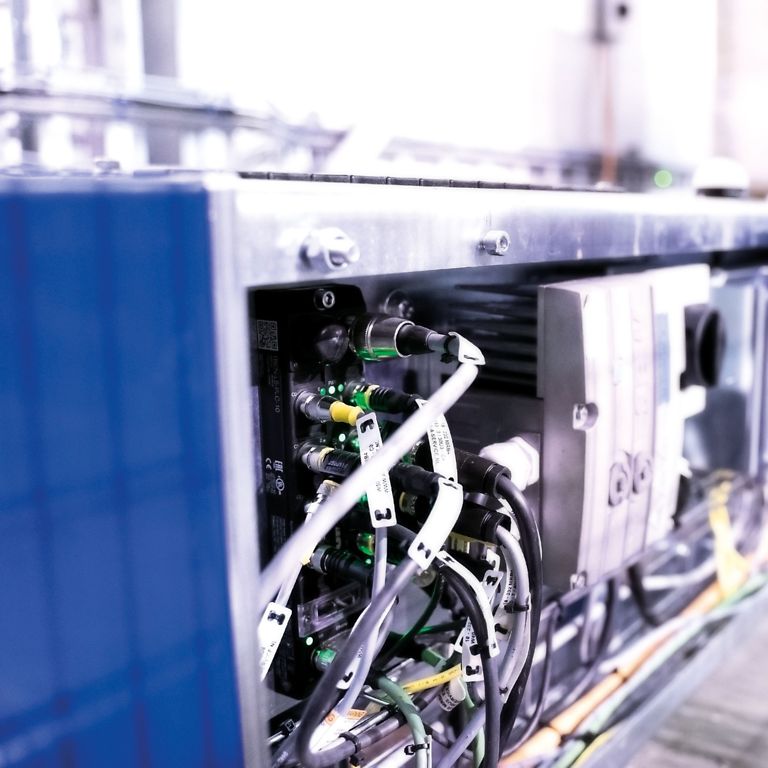

Automation power for safe food production

How do you increase your OEE when food safety, product quality, and efficiency are all top priorities?

With a partner whose robust RFID, sensor, and I/O solutions combine maximum food safety with high availability. A partner who does not lock you into a closed system. A partner who understands your industry and works with you worldwide to drive the automation and digitalization of your production lines.

Solutions for food production

See the advantages that TURCK solutions offer in food production: data-driven and digitally networked for maximum availability and smart processes.

Find your solutions

Automation solutions and products from TURCK increase the availability and efficiency of your machines and systems in numerous industries.

Insights for food and beverage production

DDiscover relevant content for your industry, from trends and best practices to efficient automation approaches and innovative technologies that make processes more transparent, flexible, and secure.

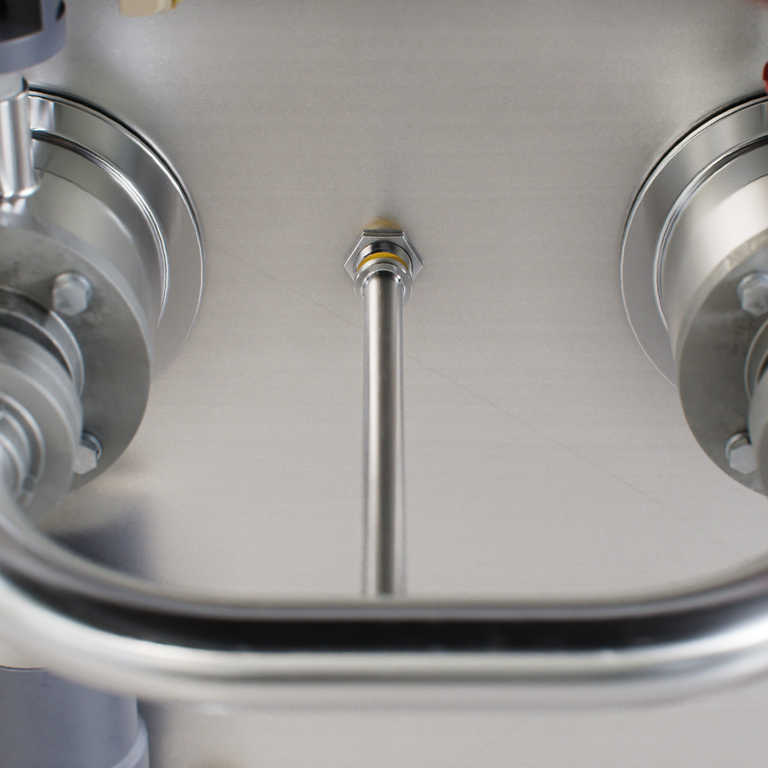

Cloud-based remote maintenance for steam generators

Certuss relies on TURCK's TX series HMI controllers for its EMX electric steam generators, including condition monitoring and remote maintenance via TURCK Cloud Solutions

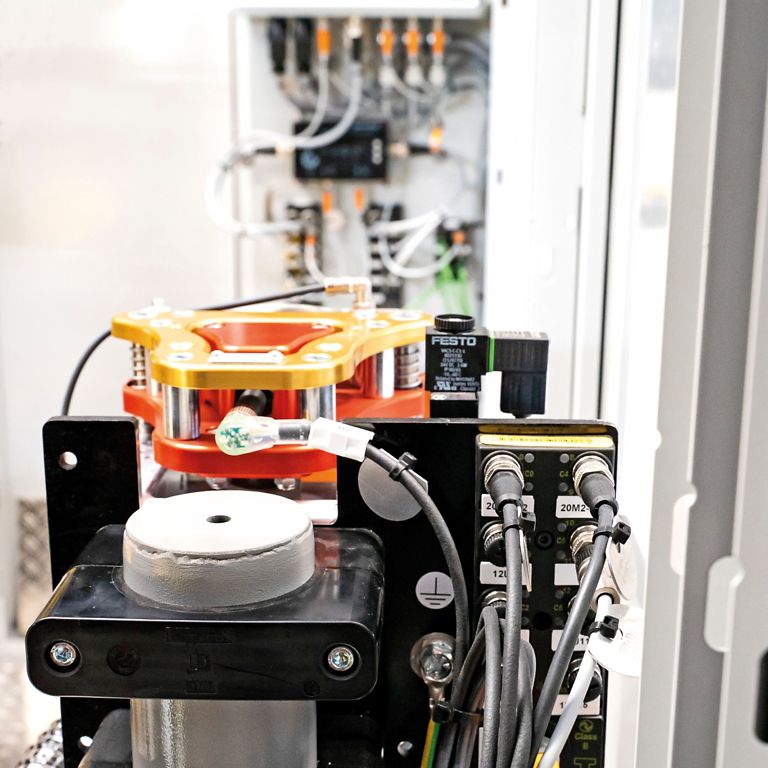

Reliable Linear Position Detection in Ex Zone 22

In order to meet the requirements of the Swiss Bühler AG for the MHSA oats peeler, TURCK has certified its non-contact Li linear position sensor for use in hazardous areas

IP67 PLC controls transport modules in cold storage

Asbreuk Service B.V. equipped a Dutch logistics service provider with a modular, fully automated truck loading and unloading system, controlled decentrally by TURCK's robust TBEN-L IP67 PLC modules at -25 °C

Contactless encoder in potato processing

In potato processing at Dutch manufacturer Schaap, TURCK's QR24 encoder demonstrates the advantages of its contactless measuring principle on a buffer conveyor

Fast audits and compliance

End-to-end data for complete documentation for FDA inspections and other audits.

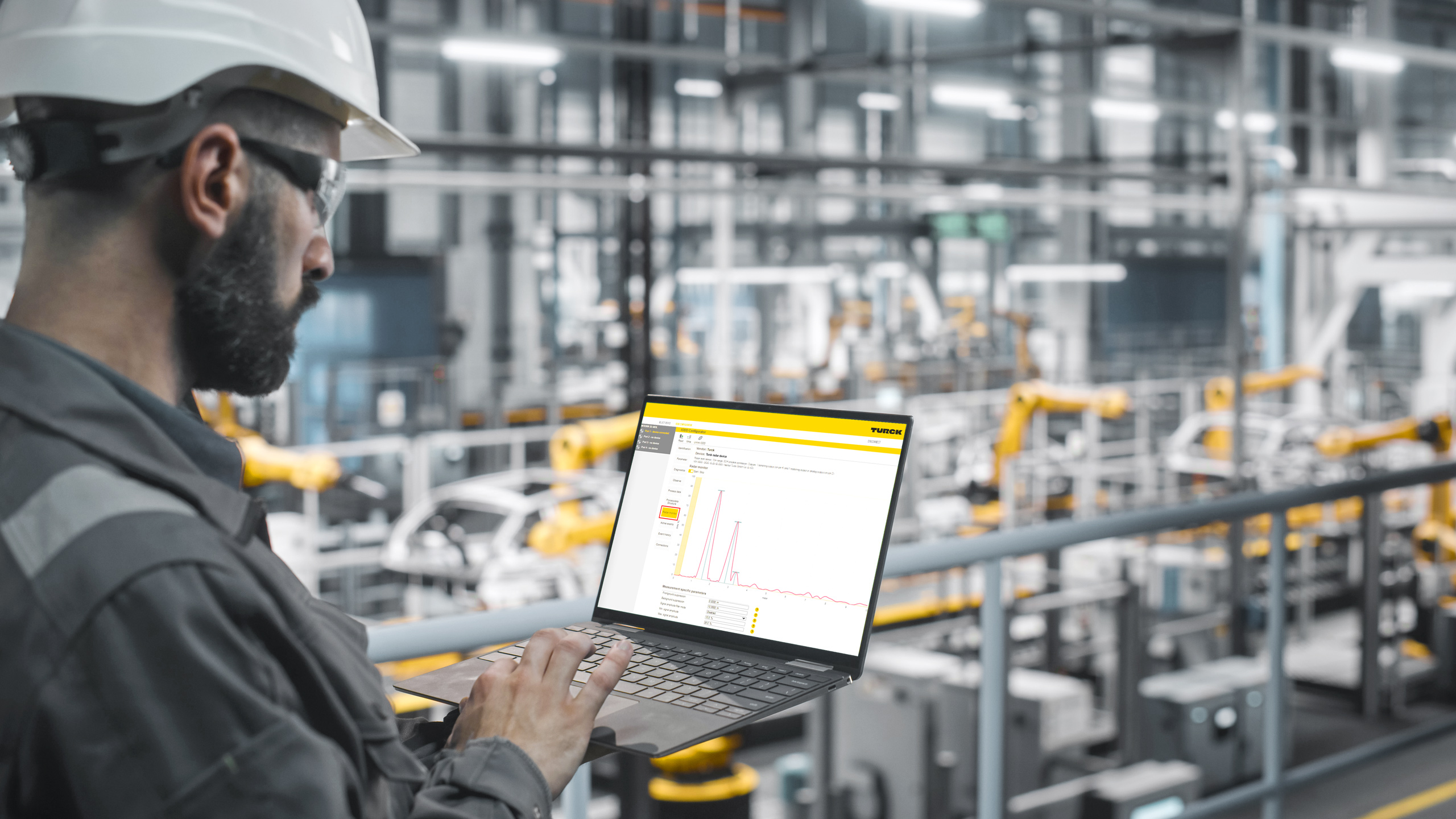

Maximum available lines

Robust hardware coupled with smart data for predictive maintenance protects against unplanned plant downtime.

End-to-end traceable production

RFID and sensor technology create transparency from the raw material through to delivery.