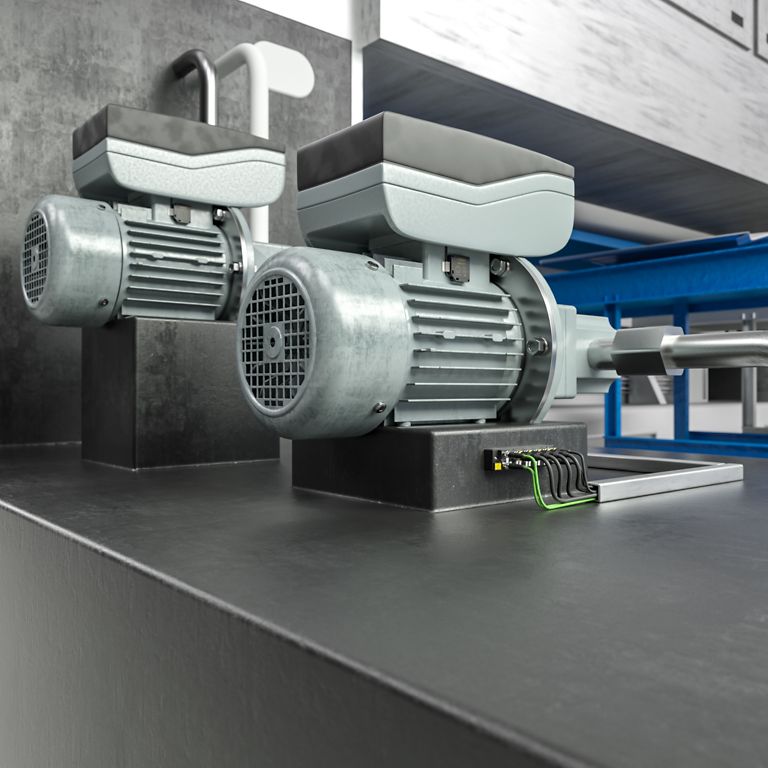

Unusual engine vibrations? High temperature in the field device? Foam formation in the tank? Getting close to maximum operating hours of interchangeable tools?

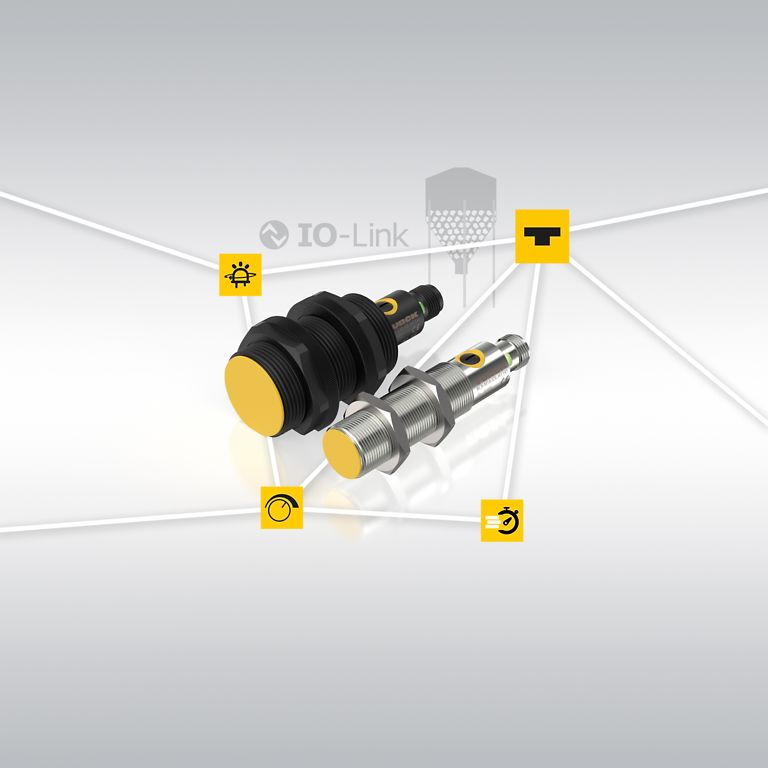

As soon as status information is sent from the sensor to the IIoT in a targeted manner, status queries become digital added value. Find out more about Turck's versatile system solutions for new systems — whether you want to collect data directly on the machine (IP67) or in the control cabinet (IP20).

Put additional information to good use

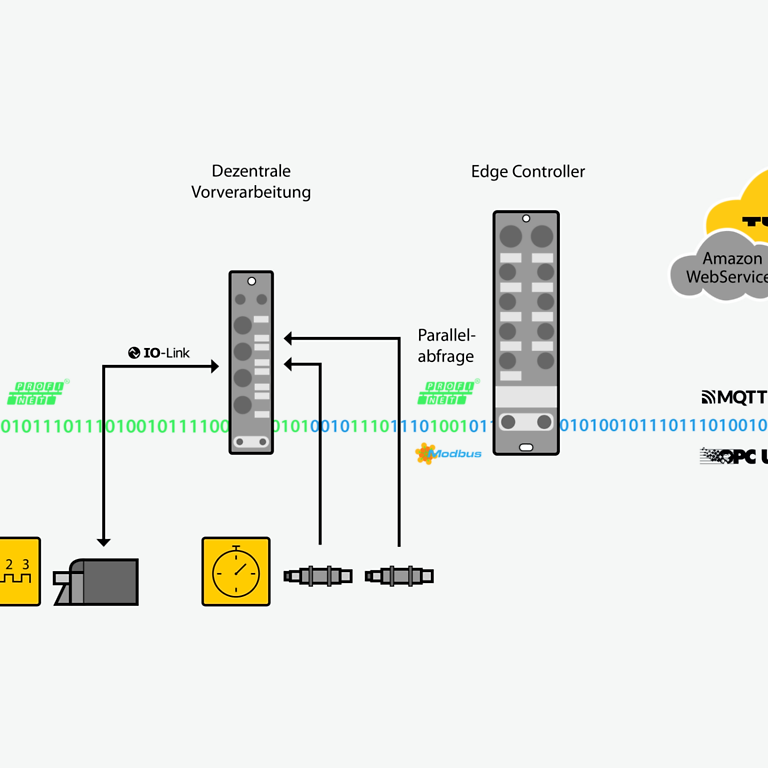

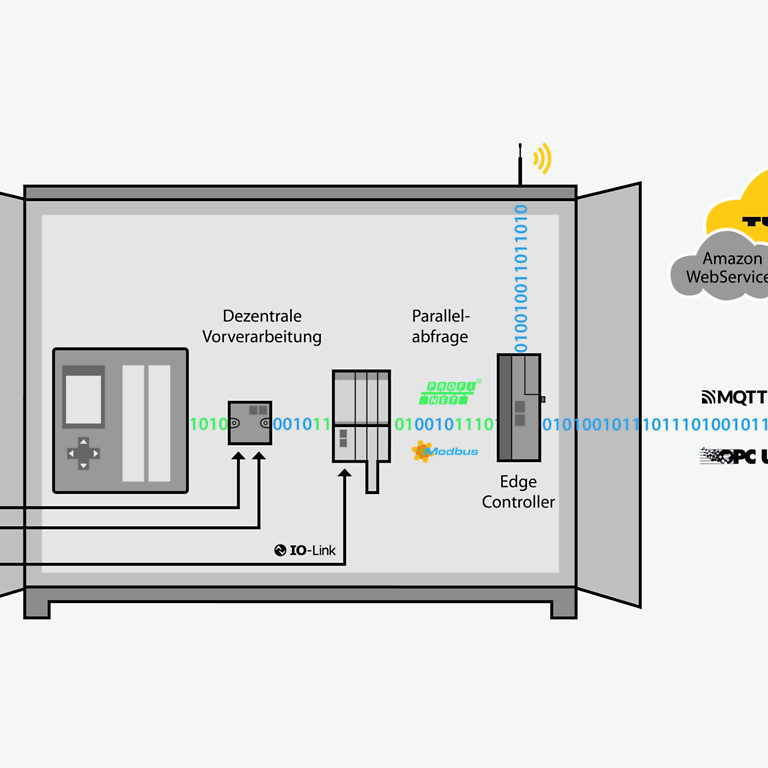

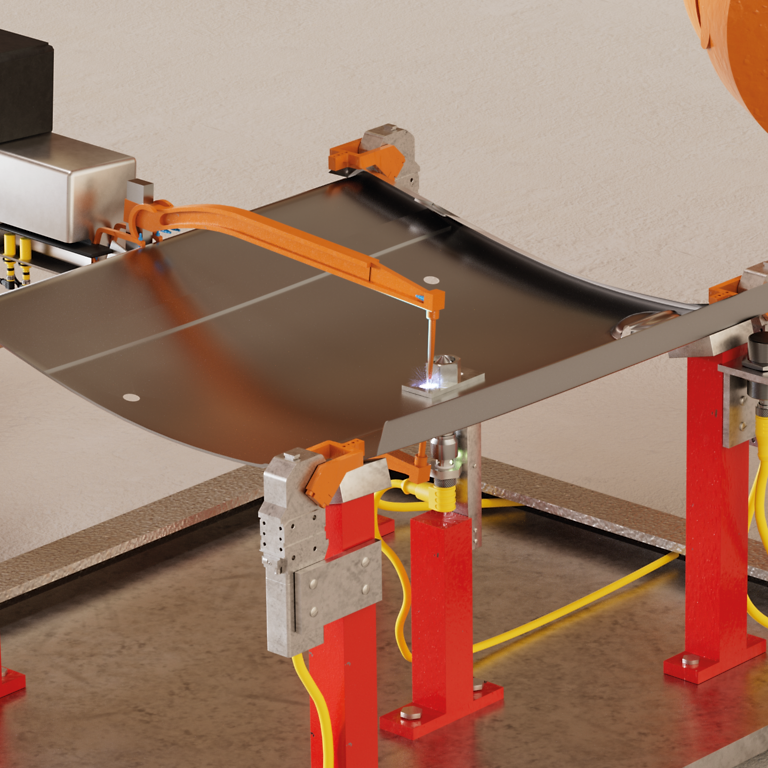

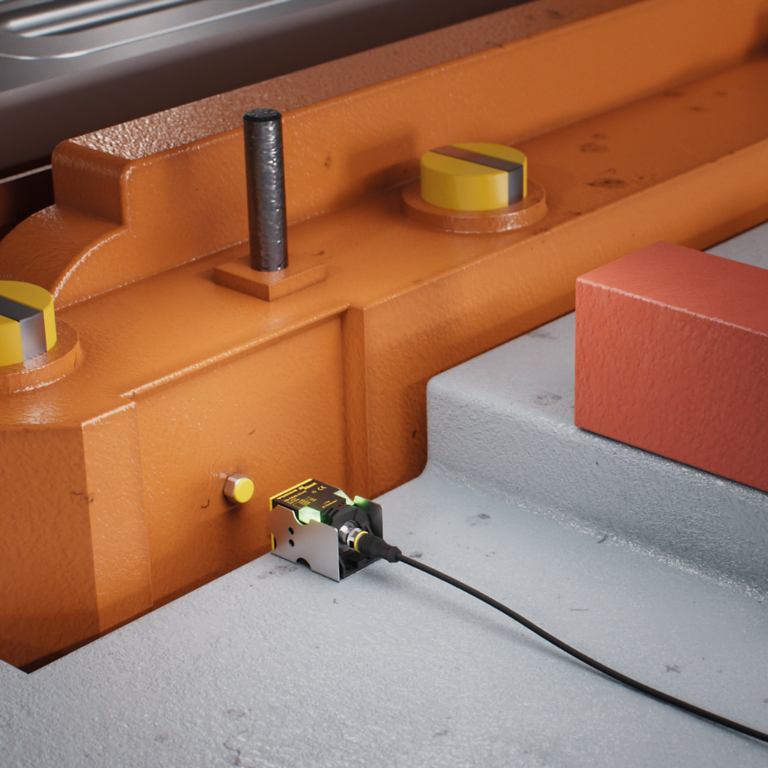

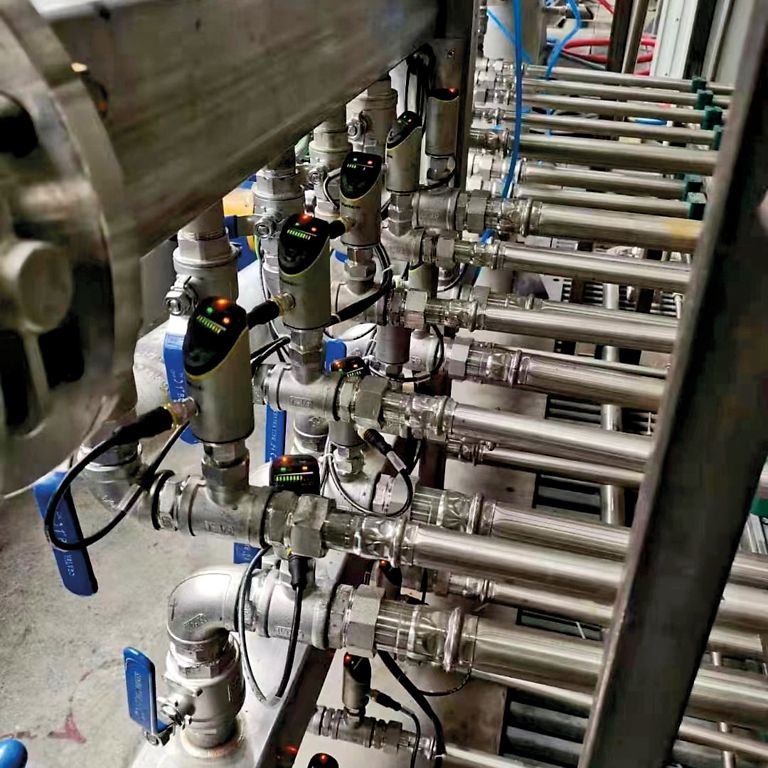

In order to monitor critical values, a separate sensor is usually not required for condition monitoring tasks. Instead, IO-Link devices supply both process data and acyclic device data, i.e. parameters or diagnostics. A standard sensor can also provide important additional information using the appropriate fieldbus station. The ARGEE programming environment allows you to easily store conditions and actions—from simple to complex—in Turck's IP67 block I/O modules.

Direct path to IIoT

Turck's Ethernet-enabled I/O hardware supports three protocols: Profinet, EtherNet/IP and Modbus TCP. Because of this "multilingualism," I/O systems or block modules can transfer pre-processed status data to an edge controller via a dedicated protocol without impairing the communication of process data to the controller. Depending on the monitoring requirements, the information flow from there leads either to the process control system or to a cloud, for example via OPC UA or MQTT.

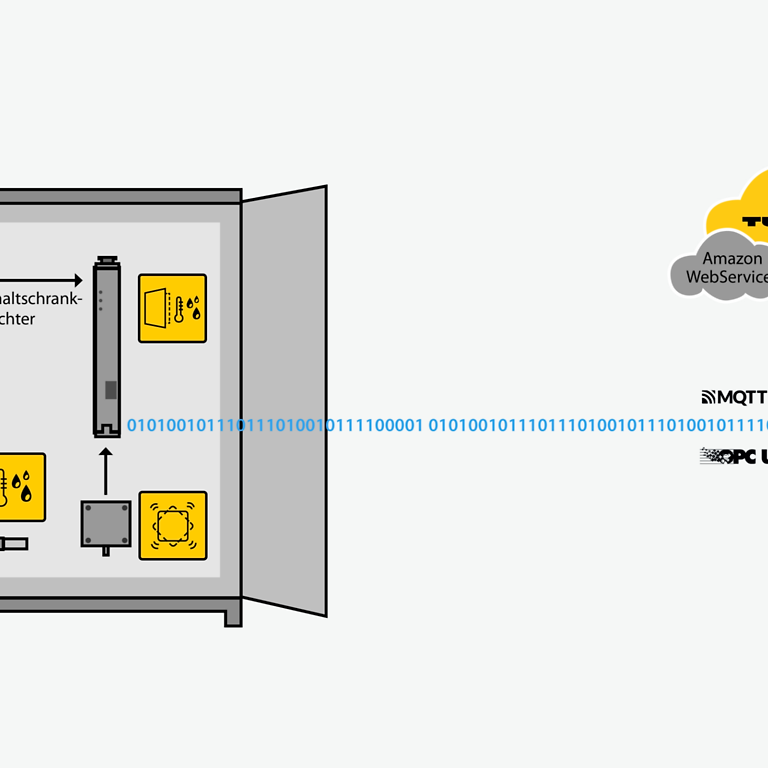

Control cabinet at a glance

Increased temperatures, high humidity or improperly closed doors are just a few of the many potential hazards for control cabinets and their sensitive components. Users can play it safe with compact control cabinet monitors that keep an tabs on important values via internal or external sensor. Turck's IM18-CCM even sends this data to the IT environment via Ethernet.