Webinar: Machine Digitization with IO-Link

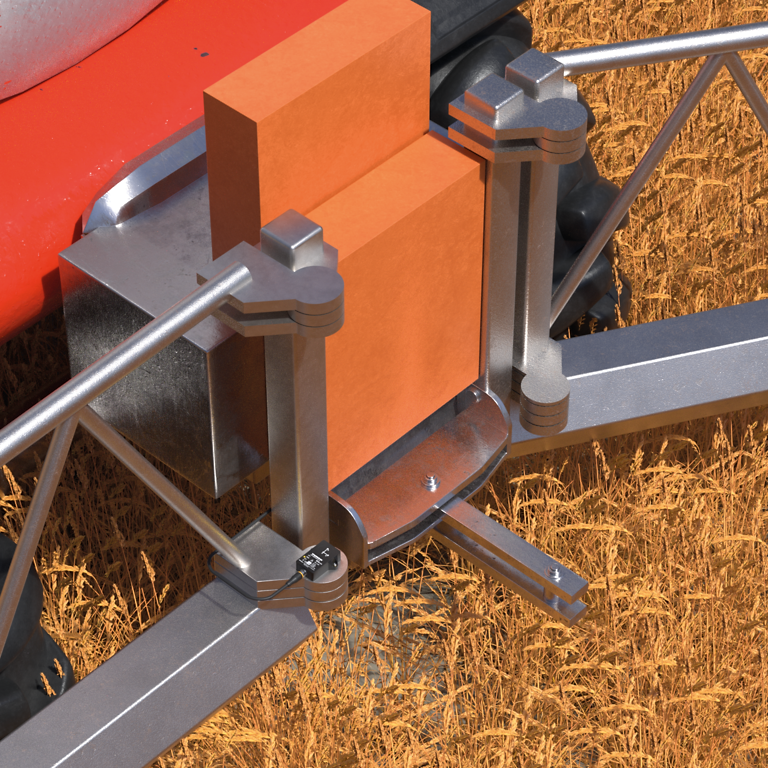

How can you significantly reduce assembly costs? What data helps you to better understand your machine? Answers to these and other questions can be found in the English webinar recording “Machine Digitization with IO-Link” by Dustin Küpper, Product Manager Position/Proximity Sensors.

In this webinar, you will learn:

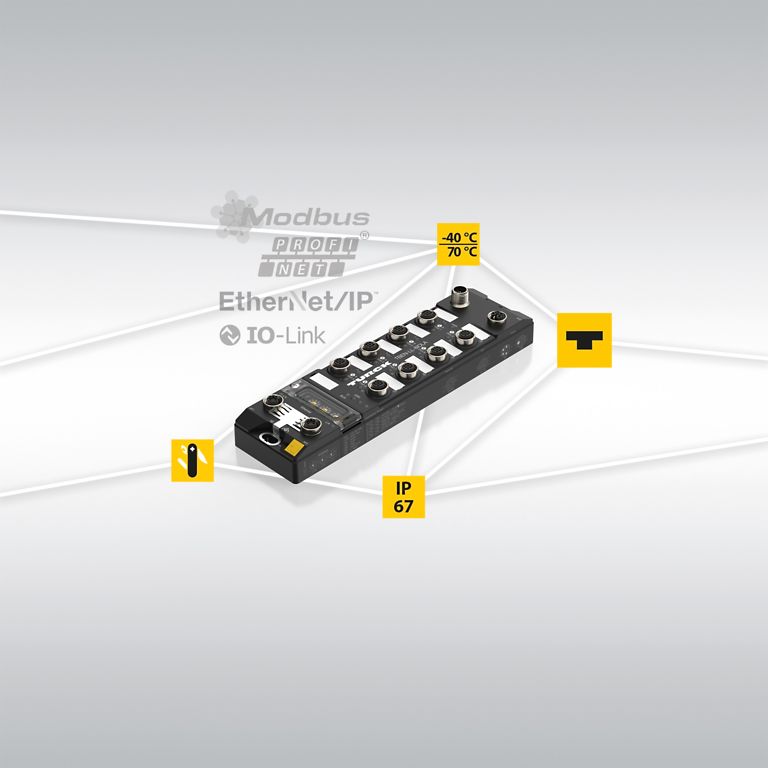

- How to reduce commissioning time and build more efficient I/O networks

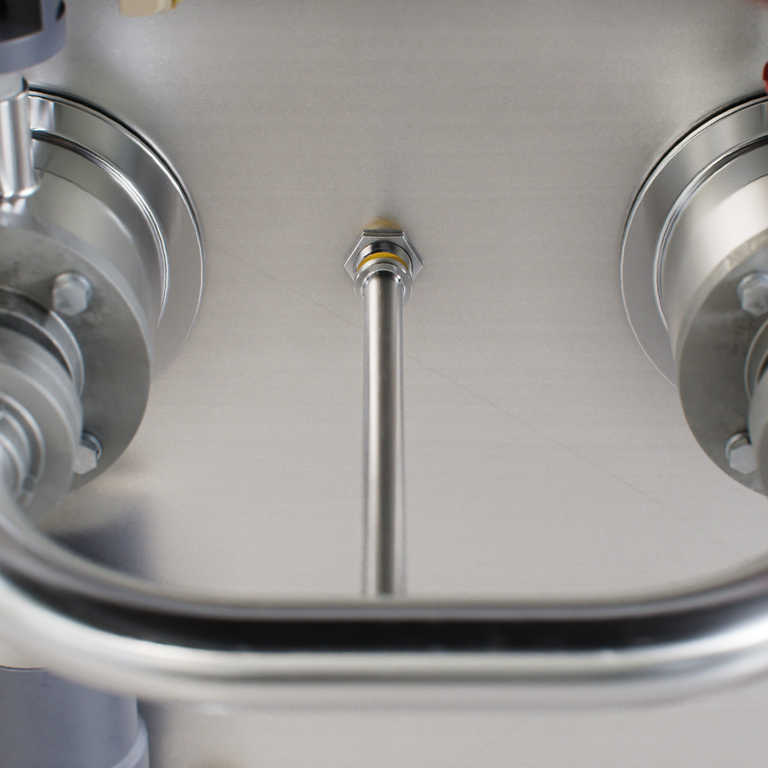

- How IO-Link enables condition monitoring with data on the status and condition of the machine

- Why usage, lifecycle information, and operating hours can be important

- What IO-Link has to do with the digital twin